Related Blogs

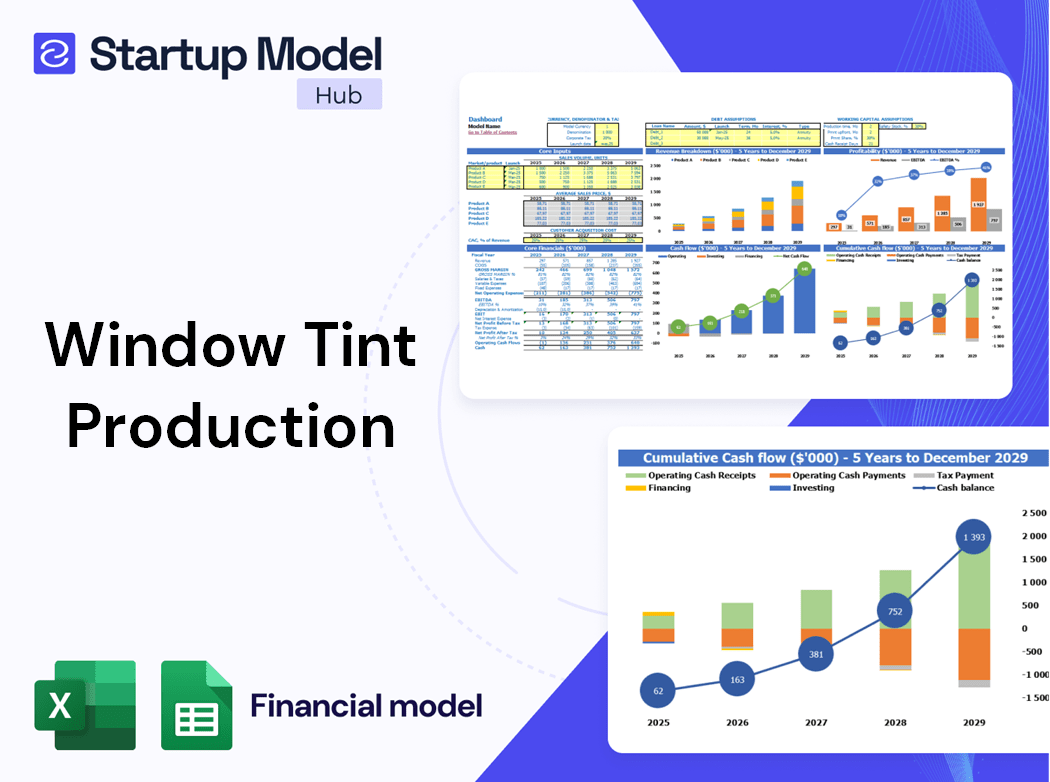

Are you ready to elevate your window tint production business? Understanding the core 7 KPI metrics is essential for tracking success and making informed decisions. From the Production Efficiency Ratio to Net Profit Margin, knowing how to calculate these metrics can significantly impact your bottom line. Dive deeper into this crucial aspect of your business by exploring our comprehensive financial model tailored for the window tint industry at Financial Model Templates.

Why Do You Need To Track KPI Metrics For Window Tint Production Business?

Tracking KPI metrics for window tint business is essential for maintaining operational excellence and achieving financial success. In the competitive landscape of the window tint industry, understanding key performance indicators (KPIs) allows businesses like ClearVision Tints to make informed decisions that drive growth and sustainability.

Here are several reasons why monitoring these metrics is vital:

- Performance Measurement: KPIs provide measurable insights into production efficiency and overall business performance, enabling companies to identify areas for improvement.

- Financial Health: Tracking financial metrics for window tint helps in understanding profitability and cost management. For instance, a company with a net profit margin of 15% is performing well, while below 5% may indicate financial distress.

- Operational Efficiency: Metrics such as average production time indicators and material waste in manufacturing help in optimizing processes, ultimately reducing costs and increasing output.

- Customer Satisfaction: Monitoring customer satisfaction metrics ensures that the products meet market demands, fostering customer loyalty and repeat business.

- Strategic Alignment: KPIs allow businesses to align their operational goals with long-term strategies, ensuring that daily activities contribute to overarching business objectives.

- Market Competitiveness: Regularly reviewing window tint industry benchmarks against internal KPIs can highlight competitive advantages or weaknesses, guiding strategic initiatives.

For example, companies that effectively track their employee productivity in manufacturing can achieve up to a 20% increase in output by addressing inefficiencies. Furthermore, the use of a KPI dashboard for window tint companies can streamline data visualization, making it easier to identify trends and make quick adjustments.

Tips for Effective KPI Tracking

- Utilize software tools to automate data collection and reporting for real-time insights.

- Regularly review and adjust KPIs to ensure they remain aligned with market conditions and business goals.

- Engage employees in the KPI process to foster a culture of accountability and continuous improvement.

Ultimately, the importance of KPIs in production cannot be overstated. They serve as the backbone of strategic decision-making, helping businesses like ClearVision Tints navigate challenges and seize opportunities in the evolving window tint market.

What Are The Essential Financial KPIs For Window Tint Production Business?

In the competitive landscape of the window tint production sector, financial metrics for window tint businesses play a crucial role in determining success and sustainability. For a company like ClearVision Tints, focusing on essential financial KPIs helps track profitability, manage costs, and ensure overall business health.

- Net Profit Margin: This metric indicates the percentage of revenue that exceeds total expenses. A healthy net profit margin for window tint businesses typically ranges from 10% to 20%. To calculate, use the formula:

Net Profit Margin (%) = (Net Profit / Revenue) x 100

- Return on Investment (ROI): Measuring the ROI is essential for evaluating the profitability of investments in production and marketing. An ROI above 15% is generally considered acceptable in the manufacturing industry. The formula for ROI is:

ROI (%) = (Net Profit / Cost of Investment) x 100

- Sales Growth Rate: Tracking the annual increase in sales helps gauge market trends and customer preferences. A typical growth rate of 5% to 10% annually is ideal for window tint production. It is calculated as follows:

Sales Growth Rate (%) = [(Sales This Year - Sales Last Year) / Sales Last Year] x 100

- Average Production Cost Per Unit: Understanding the cost associated with producing each unit of window tinting film is vital. Aiming for a production cost below $100 per unit can enhance profit margins. Calculate it using:

Average Production Cost Per Unit = Total Production Costs / Total Units Produced

- Material Waste Percentage: Keeping material waste below 5% is crucial for maintaining profitability. This is calculated as:

Material Waste Percentage = (Waste Material / Total Material Used) x 100

Tips for Effective KPI Tracking

- Regularly update your financial KPI dashboard to reflect changes in the market and production.

- Benchmark against industry standards to ensure your KPIs align with window tint industry benchmarks.

- Involve key team members in KPI discussions to develop a cohesive strategy for financial health.

By diligently monitoring these core KPIs for manufacturing, ClearVision Tints can make informed decisions that drive growth, improve efficiency, and maintain competitiveness in the window tint production market. Proactive KPI management ensures that the company aligns its financial strategies with its long-term goals, paving the way for sustainable success in an evolving industry landscape.

Which Operational KPIs Are Vital For Window Tint Production Business?

In the window tint production industry, tracking operational KPIs is essential for enhancing efficiency and ensuring high-quality output. These KPIs help businesses like ClearVision Tints monitor internal processes, optimize workflow, and maintain a competitive edge. Below are the core operational metrics critical for assessing performance:

- Production Efficiency Ratio: This KPI measures the efficiency of production processes. Aiming for a ratio of 85% or higher can indicate a well-optimized manufacturing system.

- Average Production Time Per Unit: This metric calculates the time required to produce one unit of tinted film. The industry standard is typically around 30 minutes, but reducing this time can significantly enhance productivity.

- Material Waste Percentage: Tracking the percentage of raw material wasted during production is crucial. The goal should be to keep this metric below 5% to ensure profitability and sustainability in operations.

- Employee Productivity Rate: Measuring the output per employee can reveal operational strengths and weaknesses. Aiming for productivity levels of 75-80% is often seen as optimal in manufacturing.

- Customer Satisfaction Score: This metric gauges how well the products meet customer expectations. A score above 90% typically reflects a successful alignment with market demands.

- Return on Equipment Investment (ROEI): Calculating the return on investment in machinery is vital for understanding asset effectiveness. A benchmark of 15-20% return is usually expected within the first few years of equipment acquisition.

Tips for Effective KPI Tracking

- Implement a KPI dashboard to visualize and monitor operational metrics regularly.

- Set clearly defined goals for each operational KPI to facilitate continuous improvement.

- Use digital tools to automate data collection for accurate and timely KPI reporting.

These operational KPIs not only provide insights into production efficiency, but also impact overall profitability and customer satisfaction in the window tint industry. Regularly reviewing and updating these metrics ensures that businesses like ClearVision Tints stay agile and responsive to market trends.

How Frequently Does Window Tint Production Business Review And Update Its KPIs?

In the dynamic field of window tint production, regularly reviewing and updating KPI metrics for window tint business is critical for staying competitive and ensuring operational efficiency. For businesses like ClearVision Tints, a suggested review frequency is at least quarterly to assess and recalibrate performance against set objectives. This approach allows for an agile response to market changes and internal challenges.

Tracking methods should include a combination of both financial metrics for window tint and operational metrics for window tint. This dual focus not only provides a comprehensive view of business health but also facilitates strategic decision-making.

Specific benchmarks for different KPIs can be set annually, with adjustments made based on industry benchmarks. For instance, a typical net profit margin in the window tint industry is around 10-15%, whereas companies may aim for an employee productivity rate enhancement of at least 5-10% year-on-year.

Tips for Effective KPI Review

- Utilize a KPI dashboard for window tint companies that consolidates data visually for timely insights.

- Involve cross-functional teams during KPI reviews to gather diverse perspectives.

- Regularly benchmark against competitors to identify areas needing improvement.

Additionally, businesses should not overlook the importance of ensuring that KPI tracking methods are efficient and scalable. Implementing automated data collection tools can significantly reduce manual errors and provide real-time insights, ensuring that the importance of KPIs in production is maximized.

Lastly, the integration of strategic business KPIs is paramount. These should align with long-term goals, such as sustainability initiatives and market expansion strategies. Establishing clear objectives for each KPI, such as a targeted sales growth rate of 10-20% per quarter, will guide the business towards achieving its overarching mission.

What KPIs Help Window Tint Production Business Stay Competitive In Its Industry?

In the highly competitive window tint production industry, tracking the right KPI metrics for window tint business is crucial for staying ahead. These metrics help businesses like ClearVision Tints optimize operations, improve financial health, and enhance customer satisfaction. By focusing on essential KPIs, companies can navigate challenges and seize market opportunities effectively.

Some of the most impactful KPIs that can help window tint production businesses remain competitive include:

- Production Efficiency Ratio: Measuring the amount of output relative to input can help identify bottlenecks and streamline operations. Aiming for an efficiency ratio above 80% is typically considered optimal in manufacturing.

- Customer Satisfaction Score (CSAT): Monitoring customer feedback and satisfaction levels is vital. Aiming for a CSAT score exceeding 90% can significantly enhance customer loyalty and retention.

- Material Waste Percentage: Keeping track of material waste is essential for sustainability and cost-effectiveness. Businesses should strive to maintain waste below 5% to improve profitability metrics for businesses.

- Average Production Time Per Unit: Calculating the time taken to produce a unit can pinpoint inefficiencies. A target of under 3 hours per unit is a standard benchmark.

- Net Profit Margin: This financial metric should be closely monitored, with a target of at least 15% for a healthy bottom line in the window tint industry.

- Sales Growth Rate: Tracking the percentage increase in sales year-over-year is critical for assessing market position. A favorable growth rate of over 10% annually is ideal.

- Return On Investment (ROI): This indicates the profitability of investments in production capacity or technology, with an ROI above 20% being a common benchmark.

- Employee Productivity Rate: Monitoring how much output each employee generates can provide insights into workforce efficiency. A productivity rate exceeding 100% is a strong indicator of a well-run operation.

- Market Share Percentage: Understanding one’s share of the market can guide strategic decisions. Aiming for a market share growth of more than 5% annually is often a goal for competitive businesses.

Employing KPI tracking methods such as dashboards and regular reporting can ensure that these key metrics are continually monitored and adjusted. By leveraging window tint industry benchmarks, companies can better understand where they stand in relation to competitors.

Tips for Effective KPI Monitoring

- Regularly review your KPI dashboard to stay informed about performance and adjust strategies as needed.

- Engage your employees in understanding the importance of KPIs; their involvement can lead to innovations and improvements.

- Benchmark your KPIs against industry standards to identify areas for enhancement and to remain competitive.

By focusing on these critical core KPIs for manufacturing, ClearVision Tints can effectively position itself within the market, meet customer demands, and drive sustainable growth.

How Does Window Tint Production Business Align Its KPIs With Long-Term Strategic Goals?

Aligning window tint production KPIs with long-term strategic goals is essential for businesses like ClearVision Tints to stay competitive in an evolving market. By carefully selecting and tracking key performance indicators (KPIs), companies can ensure that their operations not only meet immediate production needs but also support broader objectives such as sustainability, customer satisfaction, and market growth.

Establishing strategic business KPIs that resonate with long-term goals involves the following steps:

- Identify Key Objectives: Goals may include increasing market share, enhancing customer loyalty, and promoting eco-friendly practices. Align KPIs such as customer satisfaction scores and market share percentage with these objectives.

- Measure Financial Performance: Utilize financial metrics for window tint production, like net profit margin and sales growth rate, to evaluate the business's fiscal health and sustainability.

- Track Operational Excellence: Operational KPIs, such as material waste percentage and average production time per unit, help streamline processes to meet environmental goals and enhance product quality.

- Regular Reviews and Adjustments: Consistent evaluation of KPIs ensures that they remain relevant to the business's strategic goals. Reviewing KPIs in window tint production should occur quarterly or bi-annually to adapt to market changes.

The window tint industry benchmarks reveal that companies with aligned strategies and KPIs tend to outperform their competitors. For example, organizations that implement effective KPI tracking methods often see a reduction in material waste in manufacturing by as much as 20% while improving production efficiency KPIs.

Tips for Aligning KPIs with Long-Term Goals:

- Involve stakeholders in the KPI-setting process to ensure accountability and commitment across all levels of the organization.

- Utilize a KPI dashboard for window tint companies to visually track progress and adjustments over time.

- Benchmark against industry leaders to identify gaps and opportunities in your current KPI framework.

Ultimately, aligning core KPIs for manufacturing with long-term strategic goals creates a roadmap for success in the window tint production industry. As ClearVision Tints navigates the challenges of UV exposure and heat mitigation, the careful integration of KPIs will be crucial in driving innovation and enhancing customer satisfaction.

What KPIs Are Essential For Window Tint Production Business’s Success?

Tracking the right KPIs for window tint production is crucial for the success of a business like ClearVision Tints, which aims to lead the industry in premium, eco-friendly films. These KPIs not only provide insights into operational efficiency but also guide financial strategies that drive profitability and customer satisfaction.

Here are the essential KPIs to monitor:

- Production Efficiency Ratio: This measures the output of your production processes against the inputs used. A ratio above 85% is generally considered optimal in manufacturing. This KPI helps pinpoint areas for improvement in material waste in manufacturing.

- Customer Satisfaction Score: Use surveys to gauge customer satisfaction. Scores above 80% typically indicate a thriving business. This metric is essential for assessing customer satisfaction metrics and aligning with market demands.

- Material Waste Percentage: Monitor the percentage of materials wasted during production. Keeping this under 5% is a common benchmark to strive for in the window tint industry.

- Average Production Time Per Unit: Keep track of the time taken to produce each unit. An efficient production line should aim for a time frame of under 30 minutes per unit. This KPI is critical for assessing average production time indicators.

- Net Profit Margin: Calculate your net profit margin by dividing net income by total revenue. A margin above 15% is often regarded as healthy for production businesses.

- Sales Growth Rate: Track the percentage increase in sales over a specific period. A growth rate of at least 10% annually is a solid target for sustainable growth.

- Return On Investment (ROI): Measure your ROI by comparing the profit gained from investments against their cost. An ROI of over 20% is generally seen as favorable.

- Employee Productivity Rate: Assess productivity by measuring the output per employee. A good benchmark is at least $75,000 in sales per employee annually in the window tint sector.

- Market Share Percentage: Regularly analyze your sales relative to the total market size. Aiming for a market share above 10% positions your business favorably against competitors.

Tips for Effective KPI Tracking

- Utilize a KPI dashboard for window tint companies to visualize critical metrics for quick assessment.

- Regularly review KPIs against window tint industry benchmarks to ensure you remain competitive and aligned with market standards.

Adopting these core KPIs for manufacturing will not only allow ClearVision Tints to optimize operations but also enhance financial performance and customer engagement. By effectively implementing and regularly reviewing these metrics, the business can continually adapt to market conditions and customer expectations.

Production Efficiency Ratio

The Production Efficiency Ratio (PER) is a crucial KPI metric for window tint production businesses like ClearVision Tints. This metric provides insights into how well the production process converts raw materials into finished products. A higher ratio indicates a more efficient production process, leading to better profitability and sustainability.

To calculate the Production Efficiency Ratio, use the following formula:

PER = (Total Output / Total Input) x 100

Where:

- Total Output: The total amount of product produced in a specific timeframe.

- Total Input: The total amount of resources (materials, labor, etc.) used in production during that timeframe.

In the window tint production industry, industry benchmarks typically suggest that a PER greater than 85% is indicative of a well-optimized process. Businesses falling below this threshold may need to investigate their operations for waste reduction opportunities, particularly in areas like material waste and labor efficiency.

According to recent industry data, the average PER for successful window tint manufacturers ranges between 75% and 90%. Companies achieving a PER above 90% often benefit from lower operational costs and higher customer satisfaction due to shorter lead times and consistent product quality.

Tips to Improve Production Efficiency Ratio

- Invest in training programs to enhance employee productivity in manufacturing processes.

- Utilize real-time data tracking systems to monitor production efficiency and identify bottlenecks.

- Implement lean manufacturing principles to minimize waste and streamline production workflows.

By actively monitoring the Production Efficiency Ratio, ClearVision Tints can gain valuable insights into their operational metrics for window tint production. This not only helps in optimizing resource allocation but also supports long-term strategic goals such as increasing profitability and market share.

The alignment of this KPI with other financial metrics for window tint businesses, such as the Net Profit Margin and Sales Growth Rate, is vital for driving comprehensive performance improvement. For example, a 5% increase in PER can result in a significant reduction in production costs, enhancing overall profitability.

| KPI Metric | Calculation Formula | Industry Benchmark |

|---|---|---|

| Production Efficiency Ratio | (Total Output / Total Input) x 100 | > 85% |

| Material Waste Percentage | (Material Waste / Total Input) x 100 | < 5% |

| Average Production Time Per Unit | Total Production Time / Total Units Produced | < 2 hours/unit |

Effective tracking methods for this KPI include implementing a KPI dashboard for window tint companies. This dashboard can visually represent production data over time, making it easier to identify trends and areas for improvement.

Ultimately, the Production Efficiency Ratio serves as a foundational metric in the broader spectrum of operational KPIs to monitor in window tint production. By focusing on this core KPI, ClearVision Tints can not only meet the demands of the market but also enhance its overall strategic positioning within the window tint industry.

Customer Satisfaction Score

The Customer Satisfaction Score (CSAT) is a critical KPI metric for window tint production businesses like ClearVision Tints. This metric gauges how products and services meet customer expectations, playing a pivotal role in building brand loyalty and enhancing market reputation. In a highly competitive window tint industry, where customer preferences swiftly evolve, monitoring CSAT is essential.

To calculate the CSAT, businesses typically employ a straightforward formula:

CSAT = (Number of Satisfied Customers / Total Number of Respondents) x 100

For instance, if 80 out of 100 customers express satisfaction with their experience with your window tint products, the calculation would look like this:

CSAT = (80 / 100) x 100 = 80%

Achieving a high CSAT is particularly relevant for ClearVision Tints, which prioritizes customer feedback to drive continuous improvements in its production processes and customer service.

Tips for Improving Customer Satisfaction

- Implement a systematic feedback mechanism to gather insights from customers post-purchase.

- Analyze common complaints and address recurring issues to improve product quality.

- Train employees in customer service to enhance the overall interaction experience.

According to recent industry benchmarks, a CSAT score of around 75% to 85% is considered optimal in the manufacturing sector, including window tint production. Scores above 85% indicate exceptional service, while scores below 75% may suggest the need for strategic adjustments.

| CSAT Score Range | Description | Improvement Action |

|---|---|---|

| 90% and above | Exceptional Satisfaction | Maintain quality and seek innovations |

| 80% to 89% | Good Satisfaction | Identify areas for further enhancement |

| 70% to 79% | Moderate Satisfaction | Implement improvement plans immediately |

| Below 70% | Poor Satisfaction | Conduct comprehensive reviews and rectifications |

Additionally, integrating customer satisfaction metrics into the wider framework of KPI tracking methods will enable ClearVision Tints to align its operational and financial metrics effectively. By doing so, the business can identify trends, assess the impact of its innovations, and make informed decisions to stay competitive in the market.

Ultimately, measuring and improving the Customer Satisfaction Score is not just about responding to feedback; it’s about creating a culture of excellence that resonates with customers, aligns with strategic business KPIs, and ensures sustainable growth. For a detailed analysis of the financial aspects of running a window tint production business, including KPIs, visit this financial model resource.

Material Waste Percentage

The Material Waste Percentage is a critical KPI metric for window tint production businesses like ClearVision Tints, which focuses on sustainability and eco-friendly products. By effectively monitoring this metric, businesses can not only enhance their operational efficiency but also align their processes with their commitment to sustainability.

To calculate the Material Waste Percentage, use the following formula:

| Metric | Formula | Example |

|---|---|---|

| Total Material Used | - | 1000 kg |

| Total Material Waste | - | 100 kg |

| Material Waste Percentage | (Total Material Waste / Total Material Used) x 100 | (100 kg / 1000 kg) x 100 = 10% |

By keeping the Material Waste Percentage low, ClearVision Tints can improve production efficiency and reduce costs associated with wasted resources. In the window tint industry, benchmarks suggest that leading manufacturers aim for a waste percentage below 5%. A waste percentage higher than this can signal inefficiencies in the production process, which may lead to increased costs and lower profitability metrics for businesses.

Tips for Reducing Material Waste

- Implement lean manufacturing techniques to identify and eliminate wasteful practices.

- Invest in quality control measures to ensure that materials are used effectively.

- Train employees on best practices for handling and cutting materials to minimize offcuts.

- Regularly review and adjust production processes to improve efficiency.

In addition to improving production efficiency KPIs, monitoring the Material Waste Percentage can also enhance customer satisfaction metrics by ensuring that products meet quality standards with minimal defects. As ClearVision Tints continues to focus on eco-friendly solutions, maintaining a low material waste percentage will be integral to its brand identity and operational success.

Ultimately, the importance of KPIs in production cannot be overstated. Tracking material waste in manufacturing is not just about improving internal processes; it's about positioning ClearVision Tints as a leader in the window tint industry—committed to sustainability while delivering high-performance products. Regular reviews of KPI tracking methods will help ensure that ClearVision Tints remains aligned with its long-term strategic goals of enhancing efficiency and reducing environmental impact.

Average Production Time Per Unit

The average production time per unit is a critical operational KPI for any window tint production business, including ClearVision Tints. This metric measures the time taken to produce each unit of window film, from raw materials to finished products. By closely monitoring this KPI, manufacturers can identify efficiencies and inefficiencies in their production processes, thereby enhancing overall productivity.

In the window tint industry, the average production time can vary significantly based on several factors including the type of film being produced, machinery efficiency, and labor productivity. According to industry benchmarks, the typical production time ranges from 30 minutes to 2 hours per unit. For ClearVision Tints, targeting a production time of 45 minutes per unit would place them in a competitive position within the market.

To calculate the average production time per unit, the formula is:

Average Production Time Per Unit = Total Production Time / Total Units Produced

This calculation helps identify trends and areas that need improvement. For example, if the total production time for a batch of 100 units is 75 hours, then the average production time per unit would be:

Average Production Time Per Unit = 75 hours / 100 units = 0.75 hours (or 45 minutes)

Improving average production time not only enhances efficiency but also impacts customer satisfaction positively. Long lead times can lead to delays that may frustrate customers, especially in a market demanding quick turnaround times. Therefore, consistent monitoring of this KPI is essential in the window tint production sector.

Tips to Improve Average Production Time

- Invest in modern, efficient machinery to reduce production bottlenecks.

- Implement lean manufacturing practices to minimize waste and optimize workflow.

- Regularly train employees to enhance their productivity and operational understanding.

Additionally, understanding the factors that contribute to production delays can help in strategizing improvements. These might include:

- Machine downtime due to maintenance or failure.

- Employee absenteeism or productivity issues.

- Supply chain delays affecting the availability of raw materials.

By analyzing these elements, ClearVision Tints can set more realistic production goals and achieve operational efficiency. Furthermore, comparing their average production time against industry standards can provide insights into where they stack up against competitors, aiding in strategic planning.

| KPI Metric | ClearVision Tints Target | Industry Benchmark |

|---|---|---|

| Average Production Time Per Unit | 45 minutes | 30 - 120 minutes |

| Employee Productivity Rate | 80% | 75-85% |

| Material Waste Percentage | 5% | 3-7% |

In conclusion, tracking the average production time per unit is vital for ClearVision Tints to remain competitive, optimize their operations, and align with their long-term strategic goals. This KPI not only reflects production efficiency but also plays a significant role in customer satisfaction and financial success.

For more insights into essential financial metrics for window tint production, consider exploring our comprehensive financial model at Window Tint Production Financial Model.

Net Profit Margin

The Net Profit Margin is a crucial financial metric for any business, including those in the window tint production industry. This metric reflects the percentage of revenue that remains as profit after all operating expenses, taxes, and costs have been deducted from total revenue. For a company like ClearVision Tints, which focuses on providing premium, eco-friendly window films, understanding this metric can help gauge overall profitability and operational efficiency.

To calculate the Net Profit Margin, the formula used is:

Net Profit Margin (%) = (Net Income / Total Revenue) x 100

For instance, if ClearVision Tints generates a total revenue of $500,000 and incurs total expenses of $450,000, the net income would be $50,000. The Net Profit Margin would then be calculated as follows:

Net Profit Margin = ($50,000 / $500,000) x 100 = 10%

A 10% net profit margin indicates that for every dollar of revenue, ClearVision Tints retains a profit of 10 cents after covering all costs. This figure must be monitored closely as it serves as a benchmark for assessing the company’s financial health against industry standards.

Industry Benchmarks for Net Profit Margin

- The average net profit margin for the manufacturing sector, including window tint production, typically ranges between 5% to 20%.

- Understanding specific benchmarks aids in evaluating performance; for example, a company with a net profit margin of 15% is performing significantly better than one at 5%.

Comparing Net Profit Margin against other key performance indicators (KPIs) is essential for a comprehensive analysis. Here are some important operational KPIs for window tint production:

| Key Performance Indicator | Metric | Industry Average |

|---|---|---|

| Net Profit Margin | 10% | 5% - 20% |

| Sales Growth Rate | 8% | 5% - 10% |

| Return on Investment (ROI) | 12% | 10% - 15% |

Enhancing this profitability metric can empower ClearVision Tints to invest more in research and development, marketing, and employee training, thereby improving overall company performance. Moreover, it is essential that ClearVision Tints closely monitors factors affecting the Net Profit Margin, such as:

- Changes in production costs, especially with eco-friendly materials.

- Market price fluctuations and competitive pricing strategies.

- Operational efficiencies to minimize waste and improve margins.

Understanding the importance of KPIs in production, especially the Net Profit Margin, allows ClearVision Tints to align its business strategy with its long-term goals. This alignment ensures that resources are allocated effectively, maximizing profitability and market competitiveness.

Tips for Improving Net Profit Margin

- Regularly review pricing strategies to reflect production costs and market demand.

- Invest in training employees to enhance productivity and reduce error rates, thereby minimizing material waste.

- Explore opportunities for bulk purchasing to reduce material costs, which directly impacts profits.

By maintaining a keen focus on the Net Profit Margin, ClearVision Tints not only tracks its financial health but also positions itself strategically within the window tint production market. For those looking to delve deeper into financial modeling for window tint production, exploring resources such as this financial model can provide valuable insights and tools for setting achievable goals.

Sales Growth Rate

The Sales Growth Rate is a vital KPI metric for window tint production businesses like ClearVision Tints. It measures the rate at which sales revenue increases over a specific period, providing insights into the company's market acceptance and overall performance. In the competitive window tint industry, tracking this metric is essential for understanding how well the business is doing in comparison to its peers.

To calculate the Sales Growth Rate, you can use the following formula:

Sales Growth Rate (%) = [(Current Period Sales - Previous Period Sales) / Previous Period Sales] x 100

For example, if ClearVision Tints generated $500,000 in sales last year and $600,000 this year, the Sales Growth Rate would be:

Sales Growth Rate = [(600,000 - 500,000) / 500,000] x 100 = 20%

This indicates a robust growth trajectory, suggesting effective marketing strategies, customer satisfaction, and overall demand for eco-friendly window films.

When setting benchmarks, it is useful to compare your Sales Growth Rate against industry averages. According to the latest reports, the window tint industry has an average annual growth rate of approximately 5-10%. This means that a 20% growth rate, like that achieved by ClearVision Tints, is significantly above average, demonstrating a solid positioning in the market.

Tips for Improving Your Sales Growth Rate

- Invest in targeted marketing strategies that highlight the unique benefits of your eco-friendly products.

- Analyze customer feedback to enhance product offerings and improve customer satisfaction metrics.

- Monitor market trends to identify new opportunities and remain competitive within the window tint industry benchmarks.

Monitoring the Sales Growth Rate as part of the overall KPI tracking methods allows ClearVision Tints to pivot quickly, should market conditions shift. By focusing on both operational and financial metrics for window tint, such as customer satisfaction and material waste percentages, the company can maintain a comprehensive view of its business health.

Sales Growth Rate Benchmarks

| Industry | Average Sales Growth Rate (%) | High-Performing Companies Sales Growth Rate (%) |

|---|---|---|

| Window Tint Industry | 5-10% | 15-20% |

| Automotive Aftermarket | 6-12% | 20-30% |

| Manufacturing & Production | 4-8% | 10-15% |

ClearVision Tints can leverage its Sales Growth Rate not only to measure performance but also to set future strategic business KPIs. Growth in sales can directly influence other areas, such as investment in production efficiency KPIs and employee productivity in manufacturing.

Return On Investment (ROI)

Calculating Return on Investment (ROI) is crucial for the success of any business, including those in the window tint production industry. ROI measures the profitability of an investment relative to its cost, allowing businesses to assess the effectiveness of their expenditures in achieving profit. For a company like ClearVision Tints, with its focus on eco-friendly films, understanding ROI can help justify investments in sustainable materials and innovative production methods.

To calculate ROI for the window tint production business, the formula is straightforward:

| Formula | Components | Explanation |

|---|---|---|

| ROI = (Net Profit / Cost of Investment) x 100 | Net Profit | Total revenue generated from window tint sales minus the costs associated with production and operations. |

| Cost of Investment | Total expenses incurred in purchasing equipment, materials, and labor. |

For instance, if ClearVision Tints invests $200,000 in machinery and materials and generates $350,000 in revenue, the calculation would be:

- Net Profit = $350,000 - $200,000 = $150,000

- ROI = (150,000 / 200,000) x 100 = 75%

This figure indicates that for every dollar invested, the company earns an additional $0.75. A high ROI signifies effective investments and strong financial health, making it one of the core KPI metrics for window tint business.

Tracking ROI aligns closely with other financial metrics for window tint. It provides insights that can influence strategic decisions concerning:

- New product development

- Marketing strategies

- Operational improvements

Tips for Improving ROI in Window Tint Production

- Invest in automation technologies to streamline production and reduce labor costs.

- Regularly review operational efficiencies to identify and eliminate waste.

- Enhance customer satisfaction to stimulate repeat business and referrals, driving up sales.

Furthermore, understanding ROI as a core KPI enables ClearVision Tints to benchmark against industry standards. According to recent studies within the window tint industry benchmarks, companies with an ROI exceeding 50% are considered successful. Tracking and analyzing ROI regularly ensures that the company remains competitive, adapting strategies to maximize profitability.

In essence, ROI serves as a guiding metric that can influence various aspects of the business. By regularly calculating and analyzing ROI, businesses in the window tint production sector can make informed decisions, ultimately enhancing their market position and profitability. To delve deeper into the financial aspects of a window tint production business, consider investing in comprehensive financial modeling tools available at this link.

Employee Productivity Rate

In the window tint production business, the Employee Productivity Rate is a critical KPI that significantly influences overall operational efficiency. This metric reflects how effectively your workforce is contributing to production goals and can directly impact your bottom line. To calculate this KPI, you can use the following formula:

Employee Productivity Rate = (Total Output / Total Hours Worked)

For example, if your team produces 500 units of window tint in a 40-hour work week, the productivity rate would be:

Employee Productivity Rate = (500 units / 40 hours) = 12.5 units per hour

This number can serve as a benchmark for your business, allowing you to gauge how well your employees are performing in comparison to industry standards. According to industry benchmarks, an optimal productivity rate in the window tint production sector typically ranges between 10 to 15 units per hour.

Monitoring the Employee Productivity Rate not only helps in evaluating workforce efficiency but also serves as a guide for resource allocation, training needs, and operational improvements.

Tips for Improving Employee Productivity

- Implement regular training sessions to enhance skills and knowledge.

- Utilize technology and automation to streamline production processes.

- Establish clear performance metrics and provide feedback to employees.

- Encourage employee engagement and satisfaction through rewards and recognition programs.

In addition to tracking the Employee Productivity Rate, it is important to assess related operational metrics that contribute to overall productivity. Here are some of the vital KPIs to consider:

| KPI | Target Value | Current Value |

|---|---|---|

| Material Waste Percentage | 5% | 6% |

| Average Production Time Per Unit | 30 minutes | 35 minutes |

| Employee Turnover Rate | 10% | 12% |

By understanding how the Employee Productivity Rate aligns with these operational metrics, you can make more informed decisions to enhance efficiency in your window tint production business. Also, keep in mind that consistently reviewing your KPIs allows for agile adjustments to align with your strategic business goals, ultimately leading to improved operational performance and profitability.

Regular reviews of employee productivity also provide insights into workforce satisfaction and engagement, both of which play a pivotal role in maintaining a productive environment. Utilize various KPI tracking methods, including dashboards and monthly reports, to ensure that you stay aligned with your business objectives.

As you implement these practices, remember that the goal of tracking the Employee Productivity Rate and related KPIs is to create a workforce that is not only efficient but also motivated and engaged in their work. This will contribute to the overall success of ClearVision Tints, driving innovation and excellence in the window tint production industry.

For more detailed financial modeling and KPI analysis specific to window tint production, check out this resource: Window Tint Production Financial Model.

Market Share Percentage

Tracking the market share percentage is crucial for any window tint production business, including ClearVision Tints. It provides insights into how well the company is performing relative to its competitors within the window tint industry. By understanding market share, businesses can identify growth opportunities, optimize marketing efforts, and assess their competitive position.

To calculate market share percentage, use the following formula:

Market Share Percentage = (Company Sales / Total Industry Sales) x 100

For instance, if ClearVision Tints generates $250,000 in sales while the total sales in the window tint industry is $2,500,000, the market share calculation would be:

- Market Share Percentage = ($250,000 / $2,500,000) x 100 = 10%

A 10% market share means that ClearVision controls a notable portion of the market, which signals a strong positioning against competitors. In the window tint production industry, an ideal market share can vary, but businesses typically aim for 15% to 20% for sustained growth.

Benchmarking against industry standards is also essential to evaluate this KPI effectively. According to recent market reports, leading window tint companies generally hold a market share ranging from 12% to 18%. Monitoring these metrics allows for strategic adjustments to marketing campaigns or production capabilities.

Tips for Improving Market Share

- Conduct regular market analysis to identify trends and competitor movements.

- Engage in targeted marketing strategies that focus on attracting specific customer segments.

- Enhance product offerings with innovative and eco-friendly options that align with consumer preferences.

Implementing a strategy to improve market share should also involve evaluating customer feedback through metrics like customer satisfaction scores. Understanding customer needs can lead to enhanced product development, driving higher market penetration.

| Company | Market Share % | Sales ($) |

|---|---|---|

| ClearVision Tints | 10% | $250,000 |

| Competitor A | 15% | $375,000 |

| Competitor B | 20% | $500,000 |

Establishing a solid presence in the window tint market entails understanding both sales figures and the competitive landscape. By leveraging tools and resources, such as a comprehensive financial model, businesses can set benchmarks for their goals and continuously re-evaluate their market share in alignment with the industry's evolution.