Related Blogs

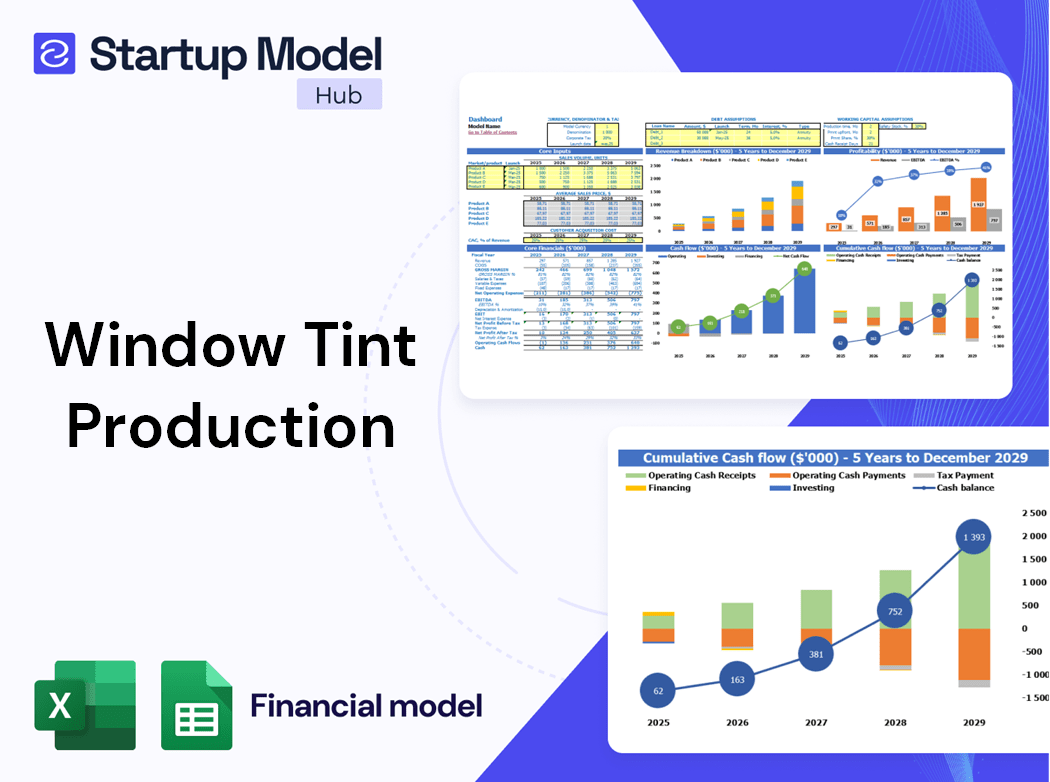

Are you considering diving into the lucrative world of window tint production? Understanding the top nine startup costs is crucial for your success. From equipment purchases to licensing fees, each expense plays a significant role in your financial planning. Curious about the details? Explore this comprehensive business plan to ensure you’re fully prepared: Window Tint Production Financial Model.

How Much Does It Cost To Start A Window Tint Production Business?

Starting a window tint production business, such as ClearVision Tints, involves several key expenses that can vary based on location, scale, and operational strategy. On average, the startup costs for a window tint business can range from $50,000 to $150,000, depending on the level of investment and the specific needs of the business.

The primary window film manufacturing expenses include:

- Equipment Purchase for Film Production: Essential equipment such as laminators, cutters, and printers can cost between $20,000 and $60,000.

- Raw Materials for Tint Film Manufacturing: Initial inventory of tint films may require an investment of around $10,000 to $30,000.

- Facility Lease or Purchase Costs: Depending on the size and location, leasing a production facility may cost between $1,500 and $5,000 monthly.

- Initial Marketing and Branding Expenses: Allocating around $5,000 to $15,000 for branding and promotional activities is crucial for market entry.

- Licensing and Permits Fees: Depending on local regulations, these fees can range from $1,000 to $5,000.

- Machinery Installation and Setup Costs: Setting up the equipment can incur costs of about $2,000 to $10,000.

- Technology and Software for Production Management: Investing in software tools for inventory and production management may cost around $1,000 to $3,000.

- Initial Staff Recruitment and Training Costs: Hiring skilled staff and training them could require an investment of approximately $5,000 to $20,000.

- Insurance Premiums for Business Protection: Obtaining necessary insurance can cost between $1,000 and $3,000 annually.

With these figures in mind, budgeting for window tint manufacturing is essential. A detailed financial plan will help in forecasting operating costs for window tint production and ensuring sustainability.

Tips for Reducing Startup Costs

- Consider a low-cost window tint production setup by sourcing second-hand equipment or leasing instead of purchasing.

- Utilize digital marketing strategies to minimize initial marketing expenses.

- Explore funding options for tint production startups such as small business loans or grants to ease financial burden.

For more detailed insights into how to finance a window tint business, including real-life statistical data and benchmarks, check out this article on profitability in window tint production: Profitability of Window Tint Production.

Is It Possible To Start A Window Tint Production Business With Minimal Investment?

Starting a window tint production business like ClearVision Tints with minimal investment is indeed possible, but it requires careful planning and strategic decision-making. The initial startup costs for a window tint business can vary widely, typically ranging from $10,000 to over $100,000 depending on the scale of operations and the type of equipment used. However, there are ways to significantly reduce these expenses.

One of the key factors in minimizing costs is to focus on essential equipment and prioritize quality over quantity. For instance, instead of investing in a full suite of state-of-the-art machinery, consider starting with low-cost window tint production setup options that still meet industry standards.

Here are some strategies to consider for starting with a limited budget:

Tips for Reducing Startup Costs

- Consider leasing equipment instead of purchasing it outright, which can spread costs over time.

- Utilize local suppliers for raw materials to avoid high shipping fees and support the community.

- Explore co-working spaces or shared facilities for your production to lower facility lease or purchase costs.

- Outsource non-core business functions such as marketing or accounting to freelancers rather than hiring full-time staff.

- Implement a pre-sale strategy to generate revenue before making significant investments in production.

Additionally, analyzing window film manufacturing expenses closely can help identify where you can cut costs. For example, choosing eco-friendly materials can often lead to cost savings in the long run due to potential tax incentives and a growing consumer base interested in sustainable practices.

It’s also crucial to engage in thorough financial planning for your window tinting business. A well-prepared budget can provide clarity on operational costs and help allocate resources effectively. According to research, businesses that diligently manage their startup budgets are more likely to survive their first few years, with success rates increasing up to 70% for those who actively monitor their operating costs for window tint production.

Finally, consider various funding options for tint production startups. Sources such as small business loans, grants, or crowdfunding can provide the necessary capital to launch while keeping personal investments low. Understanding the permitting requirements for window tint manufacturing and securing the necessary licenses early on can also prevent costly delays that might impact your budget.

Which Costs Can Be Reduced For A Window Tint Production Business?

Starting a window tint production business like ClearVision Tints involves several significant startup costs. However, understanding which expenses can be minimized is essential for maintaining a low-cost window tint production setup. Here are some of the top areas where you can reduce costs:

- Equipment Purchase: One of the largest expenses in window tint manufacturing is the machinery. To reduce these costs, consider purchasing refurbished equipment or leasing rather than buying outright. This can cut initial equipment costs by up to 30-50%.

- Raw Materials: Negotiate bulk purchase discounts with suppliers for tint film raw materials. Additionally, exploring alternative materials can sometimes yield lower costs without sacrificing quality.

- Facility Leasing: Instead of leasing a large space immediately, start with a smaller facility and expand as your business grows. This can save you 15-25% on initial leasing expenses.

- Initial Marketing Costs: Utilize social media and word-of-mouth marketing strategies to promote your window tinting services. Digital marketing can be more cost-effective compared to traditional advertising methods, potentially reducing marketing expenses by as much as 40%.

- Training Costs: Instead of hiring seasoned professionals, consider training entry-level employees, which can significantly cut recruitment costs. Implementing a structured training program can do this efficiently.

- Software Costs: Opt for open-source or low-cost software for managing window tint production rather than investing in expensive proprietary solutions, which can save you hundreds of dollars annually.

- Insurance Premiums: Shop around for insurance providers to find the best rates. Bundling policies may result in lower premiums, thereby reducing your insurance expenses significantly.

- Permits and Licensing: Research your local regulations to ensure you apply for the necessary permits efficiently and avoid unnecessary delays or fees, which can help you save on administrative costs.

- Operational Efficiency: Streamlining production processes can reduce waste and increase efficiency, ultimately lowering your overall operating costs for window tint production.

Tips for Reducing Startup Costs

- Network with other local tint businesses to share resources and knowledge, which can help reduce training and equipment costs.

- Consider crowdfunding or small business loans specifically designed for startups in the manufacturing sector to ease financial pressures.

By strategically reducing costs in these areas, you can manage the startup costs for your window tint business more effectively and establish a foundation for sustainable growth.

Examples of Startup Budgets for Window Tint Production Businesses

Starting a window tint production business can vary greatly in costs depending on the scale of operations and the initial investment approach. Below is an illustrative example of a startup budget that reflects the **startup costs for a window tint business** based on essential categories.

- Equipment Purchase for Film Production: $20,000 - $50,000

- Raw Materials for Tint Film Manufacturing: $10,000 - $15,000

- Facility Lease or Purchase Costs: $2,000 - $5,000 per month

- Initial Marketing and Branding Expenses: $3,000 - $10,000

- Licensing and Permits Fees: $1,000 - $3,000

- Machinery Installation and Setup Costs: $5,000 - $10,000

- Technology and Software for Production Management: $1,500 - $4,000

- Initial Staff Recruitment and Training Costs: $5,000 - $12,000

- Insurance Premiums for Business Protection: $1,000 - $3,000

Considering these factors, the total **expenses for starting a window tint production** operation can range from approximately **$48,500 to $113,000**. This variance depends largely on the scale of equipment and manufacturing capabilities you intend to implement, as well as any associated operating costs for window tint production during the initial phase.

Tips for Reducing Startup Costs

- Source used or refurbished equipment to lower window tint equipment costs.

- Consider a shared workspace to cut down on facility lease or purchase costs.

- Utilize digital marketing strategies that require minimal investment to reach new customers.

- Negotiate with suppliers for better prices on raw materials and establish relationships for bulk purchasing discounts.

If you're looking for further insights into managing **window tinting business financial planning**, consider exploring tools and templates available specifically for this industry. Resources like those found on this website can provide valuable benchmarks to refine your budget.

Ultimately, an efficient startup budget for a **window tint production business** not only addresses initial costs but also prepares for sustainability in the competitive market of tint film production. Careful planning and capital allocation will be crucial as you embark on this entrepreneurial journey.

How to Secure Enough Funding to Start a Window Tint Production Business?

Securing adequate funding is crucial for the success of your window tint production business, especially when considering the various startup costs for window tint business. A well-structured financial plan can help you identify potential funding sources and create a strong case for investors or lenders. Here are some effective strategies to finance your window tint production venture:

- Bootstrapping: Many entrepreneurs start by using personal savings or income from existing jobs. This is often the simplest way to fund initial expenses for starting a window tint company on a budget.

- Bank Loans: Traditional loans from banks or credit unions can be a viable option. Prepare a detailed business plan, including your estimated window tint manufacturing costs and expected revenue, to present to lenders.

- Government Grants and Loans: Investigate local, state, and federal programs aimed at supporting small businesses. These can provide favorable terms for funding your window tint production business.

- Angel Investors and Venture Capital: Attracting investors who are interested in sustainable businesses can provide substantial capital. Highlighting your eco-friendly approach at ClearVision Tints may resonate well with potential investors.

- Crowdfunding: Platforms like Kickstarter or Indiegogo allow you to present your business idea to the public and raise funds from interested backers who believe in your vision.

- Partnerships: Collaborating with industry veterans or businesses that complement your services could lead to shared resources and reduced costs, helping to finance aspects like equipment purchase for film production.

- Family and Friends: Don’t underestimate support from your personal network. They may be willing to invest in your venture with less stringent terms than traditional investors.

Tips for Efficient Funding

- Prepare a comprehensive budget that includes all window film manufacturing expenses and potential operational costs for window tint production.

- Demonstrate a clear understanding of the market and your unique selling proposition, such as the focus on eco-friendly products.

- Network with professionals in the industry to gain insights and potentially open doors to funding opportunities.

As you explore these funding options, consider the benefits of creating a solid business plan to outline your vision for ClearVision Tints. This plan should detail startup costs, projected revenues, and financial forecasts to attract investors and ensure your venture's long-term success. For further insights, you can refer to articles on window tint production profitability and key performance indicators at Financial Model Templates.

How to Use the Financial Plan for Your Window Tint Production Business?

A well-structured financial plan is crucial for the successful launch and sustainability of your window tint production business. It provides a roadmap for managing your startup costs, forecasting profits, and securing funding. A comprehensive financial strategy will guide your decision-making process and enable you to navigate the complex landscape of window film manufacturing expenses.

To effectively leverage your financial plan, consider the following key components:

- Startup Costs Analysis: Accurately estimate the startup costs required to start a window tinting company. This includes equipment, raw materials, facility leasing, and initial marketing expenses. For instance, window tint equipment costs can range from $10,000 to $50,000 depending on the level of automation.

- Cash Flow Projection: Develop monthly cash flow projections to forecast your revenues and expenses. This helps you understand when you might experience cash shortages and plan accordingly.

- Break-Even Analysis: Calculate your break-even point to determine how much revenue is needed to cover your operating costs for window tint production. Knowing this number allows you to set realistic sales targets.

- Funding Strategy: Your financial plan should outline potential funding options for tint production startups, such as loans, grants, or investor contributions. Make sure to include considerations for how to finance a window tint business without jeopardizing your equity.

- Budgeting for Expenses: Include all recurring costs such as insurance for your window tint production business, licensing fees, and staff salaries. A detailed budget allows you to track your spending and adjust as necessary.

Additionally, keeping your financial plan flexible is essential. Markets can change rapidly, and your ability to adapt will be crucial. Incorporate a contingency fund within your startup budget for tint business that covers unexpected costs, such as equipment repairs or sudden increases in material prices.

Tips for Effective Financial Planning:

- Regularly review and update your financial plan to accommodate market fluctuations and changing business needs.

- Utilize software for managing window tint production financials to streamline your budgeting and forecasting efforts.

- Engage with industry benchmarks from resources like this article to gauge your performance against peers.

In conclusion, a well-prepared financial plan serves as the backbone of your window tint production venture. By focusing on meticulous budgeting and strategic financial management, you can evolve your startup into a sustainable, profitable business in the competitive window tinting market.

What Are The Expenses To Start A Window Tint Production Business?

Starting a window tint production business like ClearVision Tints involves several key expenses that entrepreneurs must carefully consider. Understanding the window tint production business startup costs is essential for financial planning and securing the necessary funding. Here are the primary expenses for starting a window tint production business:

Equipment Purchase for Film Production

The initial investment in essential equipment for window tint business is significant. Equipment costs can range from $10,000 to $50,000 depending on the sophistication of the machinery needed for film production.

Raw Materials for Tint Film Manufacturing

Acquiring high-quality raw materials is crucial for producing eco-friendly films. Purchasing initial materials can cost around $5,000 to $20,000, depending on the scale of production and the quality of materials sourced.

Facility Lease or Purchase Costs

Location matters in the window tinting industry. Leasing a suitable facility typically costs between $1,000 to $5,000 per month, while purchasing a property could mean a hefty upfront investment of $150,000 or more.

Initial Marketing and Branding Expenses

To effectively reach potential customers, marketing strategies for tint production startups are crucial. Initial branding and marketing efforts could require approximately $2,500 to $10,000 for advertising, logo design, and promotional materials.

Licensing and Permits Fees

Before commencing operations, obtaining permits for window tint manufacturing is necessary. These fees can range between $500 to $2,000, depending on local regulations and requirements.

Machinery Installation and Setup Costs

Installing various machinery and ensuring they are operational can incur additional costs of around $5,000 to $10,000, which is a crucial step for effective tint film production.

Technology and Software for Production Management

Investing in software for managing window tint production can streamline operations. Budgeting approximately $1,000 to $5,000 for software solutions is essential to enhance efficiency.

Initial Staff Recruitment and Training Costs

Hiring and training staff is vital for the success of the business. Recruitment costs can vary significantly, but an initial budget of $3,000 to $15,000 should cover salaries during the training period.

Insurance Premiums for Business Protection

Insurance for window tint production business is an indispensable expense. Depending on the coverage, insurance premiums can run between $1,000 and $3,000 annually, safeguarding against potential risks.

Tips for Reducing Costs

- Consider financing options to spread out large expenses for equipment.

- Look for grants aimed at eco-friendly startups to fund initial materials.

- Network with local suppliers for discounts on raw materials and equipment.

In total, the startup costs for window tint business can range from $30,000 to well over $200,000, depending on the scale and scope of operations. Thorough budgeting for window tint manufacturing is critical, especially with the operating costs for window tint production that can accumulate as the business grows.

For a deeper insight into the financial aspects of starting a window tint production business, resources such as this article provide valuable benchmarks and data.

Equipment Purchase for Film Production

One of the most significant components of the startup costs for window tint business is the equipment needed for manufacturing tint films. Properly investing in high-quality equipment is crucial for ensuring efficiency, quality, and scalability in your window tint production business. Here, we break down some essential pieces of equipment and their associated costs.

- Film Cutting Machine: These machines range from $5,000 to $15,000 depending on brand and functionality. A reliable film cutter ensures precise cuts, which is vital for minimizing waste and improving production efficiency.

- Heat Guns: Essential for installation, heat guns can cost between $50 to $300 each. Investing in high-quality heat guns can drastically reduce the risk of film damage during application.

- Pressure Washers: Used for preparing vehicles and surfaces before application, these machines typically range from $300 to $2,000.

- UV Curing Equipment: This specialized equipment can range from $10,000 to $60,000, depending on the scale of production and technology used. It is vital for ensuring the durability and effectiveness of the tint films.

- Storage and Shelving Units: Proper storage solutions for raw materials and finished products can cost approximately $500 to $3,000.

Considering these costs, the total investment for essential window tint equipment can range from approximately $16,350 to $80,300. This is a significant portion of your window film manufacturing expenses, so it’s important to prioritize quality while also seeking ways to manage these costs.

Tips for Reducing Equipment Costs

- Consider purchasing second-hand equipment from reputable sources to save money.

- Look for package deals that include multiple types of equipment together.

- Research leasing options for expensive machinery to reduce initial investment burdens.

Furthermore, budgeting for regular maintenance of your equipment is crucial, as failing to do so can lead to unexpected breakdowns and production halts. Make sure to allocate a portion of your budget specifically for maintenance costs, which can range from 5% to 10% of the initial equipment investment annually.

| Equipment Type | Cost Range | Investment Type |

|---|---|---|

| Film Cutting Machine | $5,000 - $15,000 | Essential |

| Heat Guns | $50 - $300 | Essential |

| UV Curing Equipment | $10,000 - $60,000 | Critical |

| Pressure Washers | $300 - $2,000 | Important |

| Storage Units | $500 - $3,000 | Necessary |

Understanding the window tint manufacturing costs upfront can help you create a realistic budget as you consider funding options for tint production startups. For your financial planning, it may also be beneficial to utilize a comprehensive financial model specific to the window tint production business. This can help you visualize costs, revenue projections, and overall business viability. For more details, consider checking this resource: Window Tint Production Financial Model.

Raw Materials for Tint Film Manufacturing

In the window tint production business, sourcing high-quality raw materials is crucial for delivering top-notch products that cater to customer needs. The expenses for starting a window tint production typically encompass various materials that play a vital role in the manufacturing of tint films. Below are some of the primary raw materials you will need:

- Polyester Film: This is the base material for most window tints, providing strength and durability, with typical costs ranging from $0.50 to $1.00 per square foot.

- Adhesives: Quality adhesives are necessary to ensure proper adhesion of the tint to windows. Expect to invest around $0.20 to $0.50 per square foot for high-performance adhesive materials.

- UV Blocking Agents: These additives help protect against harmful UV rays, essential for producing effective films. Costs for these agents can be $2,000 to $5,000 depending on the quantity and quality.

- Color Dyes and Pigments: For aesthetic appeal and performance, these materials vary widely in cost but generally begin at around $500 for basic dye supplies.

- Protective Coatings: Used to enhance the durability and scratch resistance of the films, these coatings typically cost about $1,000 to $3,000 for initial quantities.

The overall window film manufacturing expenses can vary significantly based on the quality of materials and production scale. Typically, the raw materials can account for approximately 30% to 50% of the total startup costs for a window tint business.

Tips to Manage Raw Material Costs

- Establish long-term relationships with suppliers to negotiate better pricing and terms.

- Investigate bulk purchasing options to lower the cost per unit for essential materials.

- Stay updated on market trends to leverage discounts when new materials become available.

When budgeting for window tint manufacturing, it's also important to consider fluctuations in material prices. Recent data indicates that raw materials can experience a price increase of 5% to 10% annually, making it imperative to include potential future price adjustments in your financial planning.

| Raw Material | Estimated Cost Per Square Foot | Bulk Purchase Cost Estimate |

| Polyester Film | $0.50 - $1.00 | $5,000 (for 10,000 sq ft) |

| Adhesives | $0.20 - $0.50 | $4,000 (for 20,000 sq ft) |

| UV Blocking Agents | N/A | $3,000 (bulk purchase) |

| Color Dyes and Pigments | N/A | $500 (initial supply) |

| Protective Coatings | N/A | $2,000 (first stock) |

Effective budgeting for your window tint production business is essential to secure adequate funding and manage ongoing operating costs for window tint production. The link to explore a comprehensive financial model for this venture can be found here.

Facility Lease or Purchase Costs

Starting a window tint production business involves a variety of startup costs, and one of the most significant expenses you will face is the lease or purchase of a facility. The location of your business not only affects the cost but also impacts your accessibility to suppliers, workforce, and potential customers.

When planning for these window film manufacturing expenses, consider the following factors:

- Size and Layout: The size of your production facility will depend on your projected output. A smaller facility may be suitable for an initial operation, while larger spaces (2,000 - 5,000 square feet) accommodate growth.

- Location: Urban areas typically have higher lease rates. For instance, leasing a facility in a metropolitan area might cost around $15 to $25 per square foot annually, while rural areas can range from $7 to $12 per square foot.

- Type of Space: Consider whether you will lease a pre-existing industrial space that might require minimal renovations or if you will need to purchase land and construct a tailor-made facility.

The financial implications of leasing versus purchasing are considerable:

- Leasing: Allows for flexibility and lower initial investment but may result in higher long-term costs. Typical monthly leases can vary from $3,000 to $10,000 or more depending on location and size.

- Purchasing: Requires a significant upfront investment, potentially ranging from $200,000 to $1,000,000 depending on the location and size of the facility, yet you gain an asset that can appreciate over time.

Tips for Reducing Facility Costs

- Consider a shared workspace or incubator specifically designed for manufacturing to lower your initial startup budget for tint business.

- Negotiate multi-year leases for better rates and terms.

- Explore government grants or incentives for manufacturing businesses that may provide financial assistance for your facility purchase.

According to industry benchmarks, a typical startup budget for a window tinting business can allocate around 30% to 40% of total startup costs to facility expenses. For instance, if your total estimated costs reach $500,000, you could expect to spend between $150,000 and $200,000 on acquiring or leasing a facility.

| Facility Options | Cost Range (Annual) | Notes |

|---|---|---|

| Urban Leasing | $15 - $25/sq ft | High visibility and customer access. |

| Rural Leasing | $7 - $12/sq ft | Lower costs, but potential distance from suppliers. |

| Facility Purchase | $200,000 - $1,000,000 | Long-term investment with potential appreciation. |

In addition to these initial costs, ensure to budget for any necessary renovations to meet operational needs and compliance with health and safety regulations. Depending on the extent of renovations, this could add another $50,000 to $100,000 to your overall startup costs.

Acquiring the right facility for your window tint production business can set the foundation for your success, making financial planning and careful consideration of all related expenses essential for your venture.

Initial Marketing and Branding Expenses

Launching ClearVision Tints as a window tint production business involves several initial marketing and branding expenses that are crucial for establishing a market presence. These costs can significantly influence customer perception and impact sales. Let's explore the various components that contribute to these expenses.

- Brand Development: This includes creating a unique logo, color schemes, and overall brand identity. Depending on the designer's expertise, costs can range from $500 to $5,000.

- Website Creation: An informative and appealing website is essential. Professional website development can cost between $1,000 and $3,000, while ongoing maintenance may add $50 to $200 per month.

- Social Media Advertising: Platforms like Facebook and Instagram are effective for reaching potential customers. Initial advertising costs can range from $500 to $2,000 per campaign.

- Print Marketing Materials: Flyers, brochures, and business cards are essential for local visibility. Allocate around $300 to $1,000 for quality print materials.

- SEO & Online Marketing: Investing in search engine optimization helps improve visibility. This could cost between $500 and $2,000 initially, depending on the scope.

- Promotional Events: Organizing or participating in local events can build brand awareness. Budget around $1,000 to $3,000 for the event and marketing materials.

- Advertising Campaigns: Digital ads, such as Google AdWords, can drive traffic to your website. Expect to allocate at least $1,000 monthly for an effective campaign.

Having a structured budget for these marketing efforts is essential. Below is a simplified table outlining potential initial marketing costs for the startup of a window tint production business:

| Marketing Expense | Estimated Cost (Low) | Estimated Cost (High) |

|---|---|---|

| Brand Development | $500 | $5,000 |

| Website Creation | $1,000 | $3,000 |

| Social Media Advertising | $500 | $2,000 |

| Print Marketing Materials | $300 | $1,000 |

| SEO & Online Marketing | $500 | $2,000 |

| Promotional Events | $1,000 | $3,000 |

| Advertising Campaigns | $1,000/month | $1,000/month |

Tips to Optimize Marketing Expenses for Your Window Tint Business

- Utilize social media platforms for organic promotion to reduce initial costs.

- Leverage collaborations with local businesses for joint marketing efforts.

- Focus on targeted advertising to maximize the effectiveness of your marketing budget.

Effective financial planning and budgeting for the initial marketing and branding expenses can significantly reduce startup costs for a window tint business. By strategically allocating funds across different marketing channels, ClearVision Tints can successfully establish a strong brand presence while keeping window film manufacturing expenses in check. For a detailed financial model to guide your planning, consider checking this useful financial model resource.

Licensing and Permits Fees

When embarking on a window tint production business, one essential aspect to consider is the licensing and permits fees. These fees can vary significantly based on your location and the specific regulations governing your industry. In general, you should anticipate these costs as part of your initial startup costs for window tint business.

Licenses and permits are crucial for compliance with local, state, and federal regulations, ensuring that your operations are legal and sustainable. Depending on your area, you may need to acquire several permits, such as:

- Business operation licenses

- Building permits

- Health and safety permits

- Environmental permits

- Sales tax permits

On average, the total licensing and permit fees can range from $500 to $2,500, depending on the complexity of the permits required in your jurisdiction. For instance, areas with more stringent environmental regulations may impose higher fees. Additionally, businesses that manufacture products may need specific environmental permits, which can further escalate costs.

| Type of Permit | Estimated Cost | Time to Obtain |

|---|---|---|

| Business Operation License | $200 - $500 | 1 - 2 weeks |

| Environmental Permit | $1,000 - $1,500 | 4 - 8 weeks |

| Health and Safety Permit | $300 - $800 | 2 - 4 weeks |

Tips for Reducing Permitting Costs

- Research local regulations to ensure compliance and avoid fines.

- Consider applying for all necessary permits at once to potentially receive package discounts.

- Consult with experts to streamline the application process and reduce time.

In addition to direct fees, non-compliance can lead to fines or the revocation of your business license, which could have devastating impacts on your window tint manufacturing costs. Therefore, it is vital to allocate appropriate resources for ensuring that you have all necessary documentation in place.

Budgeting for these expenses for starting a window tint production involves careful planning and forecasting. Consider setting aside around 10% of your total startup budget for licensing and permits to avoid financial strain during your business launch. This allocation not only covers the fees but also provides flexibility for unforeseen costs that may arise during the application process.

Ultimately, being proactive about acquiring the right permits for window tint manufacturing will pave the way for a smoother start to your business, ensuring you can focus on growth and innovation in the industry.

Machinery Installation and Setup Costs

When venturing into the window tint production business, one of the most significant components of your startup costs involves machinery installation and setup. This phase entails various expenses associated with acquiring and operating specialized equipment required for producing high-quality window films.

The costs associated with installing machinery can vary greatly depending on the scale of your operations and the type of equipment you choose. Typically, you can expect to allocate between $20,000 to $100,000 for initial machinery, including automated cutting systems, laminators, and UV coating machines.

| Equipment | Estimated Cost | Notes |

|---|---|---|

| Automated Cutting Machine | $15,000 - $30,000 | Essential for precision cuts and reducing waste |

| Laminating Machine | $10,000 - $20,000 | Enhances durability and performance of window films |

| UV Coating Machine | $5,000 - $15,000 | Improves scratch resistance and longevity |

In addition to the initial equipment cost, there are also expenses related to installation and setup. These can include:

- Professional installation services: Typically between $2,000 and $10,000.

- Electrical work to ensure machinery is up to code: Approximately $1,000 to $5,000.

- Safety inspections and compliance testing: Ranging from $500 to $2,000.

When planning for the startup costs for your window tint business, consider the potential for additional operational expenses. Regular maintenance of machinery, which is crucial for longevity and performance, could cost approximately $1,000 to $3,000 annually. This will help ensure that your production runs smoothly and efficiently over time.

Tips for Reducing Machinery Setup Costs

- Consider purchasing used or refurbished equipment to save money.

- Leverage financing options for necessary machinery, which can ease the upfront financial burden.

- Seek out local suppliers or manufacturers that may offer discounts on bulk purchases.

It's essential to perform thorough budgeting when assessing window film manufacturing expenses. This will allow you to identify areas where you can minimize financial strain while maximizing production efficiency. Additionally, investing in software for managing window tint production can further streamline your operations and help track costs effectively.

Overall, the machinery installation and setup costs represent a critical investment in the future of your window tint production business. For comprehensive insights into budgeting and financial planning for your venture, consider utilizing specialized financial models tailored to the unique needs of the tinting industry, such as those available at this link.

Technology and Software for Production Management

In the window tint production business, efficient technology and software solutions are essential components of a successful startup. Investing in the right tools not only streamlines operations but directly impacts your bottom line by reducing operating costs and enhancing productivity. The window tint manufacturing costs can be significantly optimized by leveraging innovative production management software.

One of the primary expenses for starting a window tint production company is the technology and software needed for effective production management. Key software solutions can assist with:

- Inventory Management: Keeping track of raw materials and finished products to avoid overstocking or stockouts.

- Production Scheduling: Ensuring timely production runs based on demand forecasts.

- Quality Control: Monitoring the quality of the tint film produced to maintain high standards.

- Sales and Order Management: Streamlining the order processing from customers to ensure timely deliveries.

- Financial Tracking: Monitoring expenses for starting a window tint production and managing cash flow effectively.

Here’s a breakdown of potential software costs you might incur when establishing ClearVision Tints:

| Software Type | Estimated Cost (Annual) | Key Benefits |

|---|---|---|

| Inventory Management System | $1,000 - $3,000 | Real-time tracking and reporting |

| Production Management Software | $2,000 - $5,000 | Optimization of production workflow |

| Accounting Software | $500 - $1,500 | Financial reporting and tax preparation |

By choosing the right technology, you can not only streamline your operations but also significantly reduce your window film manufacturing expenses in the long run. Startups can explore various options, including low-cost or subscription-based software to minimize initial investment in window tint production.

Tips for Selecting Production Management Software

- Assess your specific needs: Evaluate what features are essential for your tint production process.

- Consider scalability: Ensure the software can grow with your business as you expand.

- Check for integration options: Opt for software that integrates seamlessly with other systems you are using.

With the right technology and software for managing your window tint production business, you can create a systematic workflow that enhances efficiency, ultimately leading to greater profitability. This strategic investment, while part of your startup costs for window tint business, will yield substantial returns as the company grows.

Initial Staff Recruitment And Training Costs

Starting a window tint production business like ClearVision Tints requires careful planning, particularly in the area of staffing. The initial staff recruitment and training costs can significantly impact your overall startup budget for the window tint business. Depending on the scale of operations, these costs can vary widely, but here are the primary components to consider:

- Recruitment Costs: Hiring skilled workers for production, quality control, and customer service can range from $2,000 to $10,000 per position, depending on the experience level and the local labor market.

- Training Costs: Training is critical for ensuring that staff understand the nuances of window tint manufacturing and installation. This can cost around $500 to $1,500 per employee, covering materials, time spent in training, and potential loss of productivity.

- Onboarding Expenses: Engaging temporary staffing agencies or tools for background checks and onboarding paperwork can add another $1,000 to $3,000 to the startup costs for your window tint business.

As a startup, you may consider a minimal investment in window tint production by leveraging online training platforms or local workshops to keep training expenses low while still ensuring staff are well-prepared.

Tips for Reducing Staff Recruitment and Training Costs

- Utilize online resources and training modules to significantly cut down on training expenses.

- Consider hiring part-time staff or interns to alleviate immediate staffing needs without committing to full-time salaries.

- Network with local vocational schools and universities for fresh talent, often at a lower cost.

Tracking these expenses for starting a window tint production is essential for accurate financial planning. Below is an illustrative table of estimated initial staff costs based on a small-scale operation:

| Position | Number of Employees | Recruitment Cost ($) | Training Cost ($) | Total Cost ($) |

|---|---|---|---|---|

| Production Worker | 3 | 6,000 | 2,000 | 24,000 |

| Quality Control Specialist | 1 | 4,000 | 1,500 | 5,500 |

| Sales/Customer Service | 1 | 3,000 | 1,000 | 4,000 |

| Total Estimated Staff Costs: | 33,500 | |||

In addition to direct recruitment and training costs, consider the long-term impact of your hiring decisions on the operating costs for window tint production. A well-trained workforce can enhance productivity and reduce errors in the manufacturing process, ultimately leading to lower waste and higher customer satisfaction.

When developing your budget, it’s essential to account for these window film manufacturing expenses associated with staff. A well-thought-out staffing plan will be crucial to the success of your window tint production business. For detailed financial planning and budgeting for window tint manufacturing, consider exploring additional resources such as financial models specifically tailored for window tint production.

Insurance Premiums for Business Protection

When embarking on a venture like the window tint production business, one of the critical startup costs that should not be overlooked is insurance premiums. Establishing a robust business protection plan is essential not only for compliance with regulations but also for safeguarding the assets and interests of your venture. In the world of window film manufacturing, potential risks can range from property damage to liabilities arising from customer dissatisfaction.

The average annual insurance premium for small manufacturing businesses can vary widely, but for a window tint production business, you can expect to pay somewhere between $1,200 and $3,500, depending on the coverage levels and specific risks involved. Here’s a breakdown of the types of insurance coverage you might consider:

- General Liability Insurance: Protects against third-party claims, typically costing around $400 to $1,500 annually.

- Property Insurance: Safeguards your facilities and equipment, with costs averaging $500 to $2,000 a year.

- Workers' Compensation Insurance: Mandatory in most states for businesses that employ staff, typically running around $1,000 to $3,000 based on employee numbers and payroll.

- Product Liability Insurance: Covers claims related to defects in your tint films, with annual premiums ranging from $500 to $2,000.

Tips for Reducing Insurance Costs

- Shop around and compare quotes from multiple insurance providers to find the best rates.

- Bundle multiple insurance policies for discounts.

- Implement safety protocols to minimize risks and potentially lower premiums.

In addition to the essential protection offered by insurance, investors look favorably on businesses that are adequately insured. Having solid insurance in place enhances your window tint business investment potential, signaling to stakeholders that you have planned for various scenarios. Furthermore, maintaining a financial plan that includes these necessary expenses ensures you are prepared for unexpected costs that could arise as you establish your window tinting company.

| Type of Insurance | Average Annual Premium | Coverage Description |

|---|---|---|

| General Liability Insurance | $400 - $1,500 | Covers third-party claims for property damage and injuries. |

| Property Insurance | $500 - $2,000 | Protects your facility and equipment from damage. |

| Workers' Compensation Insurance | $1,000 - $3,000 | Provides coverage for employee work-related injuries. |

| Product Liability Insurance | $500 - $2,000 | Covers defects and claims related to your tint films. |

Understanding these costs will enable you to better prepare your startup budget for tint business and ensure the sustainability of your operations. Incorporating insurance expenses into your financial planning for your window tint production business is a fundamental step that can significantly impact your path to success.