Related Blogs

Are you aware of the seven core KPI metrics essential for optimizing your oxygen plant business? Understanding how to calculate these metrics can significantly impact your operational efficiency and financial success. Dive deeper into the intricacies of these KPIs and discover how to elevate your business strategy by visiting this comprehensive business plan.

Why Do You Need To Track Kpi Metrics For Oxygen Plant Business?

Tracking KPI metrics for oxygen plant business is crucial for ensuring operational efficiency and financial viability. In the competitive landscape of oxygen production, understanding and analyzing these metrics allows businesses like Oxygen Innovations to make informed decisions that align with their strategic goals. By effectively measuring oxygen plant performance metrics, organizations can identify strengths, weaknesses, and areas for improvement.

Implementing a robust KPI tracking system can lead to significant benefits, including:

- Enhanced Operational Efficiency: By monitoring operational KPIs for oxygen business, plants can streamline processes, reduce waste, and optimize resource allocation. For instance, a study showed that plants that actively measure their energy consumption per unit produced can reduce energy costs by up to 20%.

- Financial Health Monitoring: Keeping a close eye on financial KPIs for oxygen plants helps in understanding profitability and cash flow. Regularly assessing metrics such as cost per unit of oxygen produced can improve profit margins and sustain growth.

- Quality Assurance: Tracking oxygen quality compliance rate ensures that the product meets industry standards, which is essential for maintaining customer trust and satisfaction.

- Customer Retention: By evaluating the customer satisfaction index, businesses can adapt to client needs and enhance their service offerings, which directly impacts long-term success.

Additionally, the frequency of KPI review is essential. Best practices suggest that oxygen plants should review their KPIs at least monthly to stay agile in a rapidly changing market. This regular assessment allows for timely adjustments to operations and strategy.

Tips for Effective KPI Tracking

- Utilize data visualization tools to make KPI trends more accessible and understandable for all stakeholders.

- Incorporate feedback loops to ensure that the insights gained from KPI tracking directly influence decision-making processes.

In summary, the importance of tracking KPI metrics for oxygen plant business cannot be overstated. These metrics are not just numbers; they are essential tools for driving efficiency, profitability, and competitiveness in the industry.

What Are The Essential Financial Kpis For Oxygen Plant Business?

For an oxygen plant like Oxygen Innovations, tracking KPI metrics for oxygen plant business is crucial for assessing financial health, operational efficiency, and market competitiveness. The essential financial KPIs for an oxygen plant business include:

- Revenue Growth Rate: This indicates how fast the company is expanding its sales. A consistent growth rate of 10-15% annually is considered healthy for industrial businesses.

- Gross Profit Margin: This metric reveals how much profit is made after deducting the cost of goods sold (COGS). A strong gross profit margin for an oxygen plant typically ranges from 30-50%.

- Operating Cash Flow: Positive cash flow is essential for sustainability. An oxygen plant should aim for a cash flow margin exceeding 20% of revenue.

- Return on Investment (ROI): This measures the profitability of investments made in production technology and infrastructure. An ROI of 15% or higher is desirable.

- Cost Per Unit of Oxygen Produced: This metric helps assess operational efficiency. The target cost should ideally be below $0.30 per cubic meter, depending on regional market prices.

- Debt-to-Equity Ratio: This ratio indicates the financial leverage of a company. A ratio below 1.5 is considered healthy, ensuring the business is not overly reliant on debt.

- Net Profit Margin: This reflects overall profitability. A net profit margin of 10-20% is typically achievable within the oxygen production sector.

Tips for Calculating Financial KPIs

- Regularly review financial statements to ensure accuracy in KPI calculations.

- Utilize standardized formulas for consistency, such as total revenue minus total COGS for gross profit margin.

- Benchmark your KPIs against industry standards to gauge performance effectively.

Incorporating these financial KPIs for oxygen plant businesses is imperative for maintaining operational efficiency and optimizing profitability. Understanding and measuring these metrics can significantly impact an organization’s ability to thrive in a competitive market. For a deeper dive into related financial metrics, resources such as this guide can provide valuable insights.

Which Operational Kpis Are Vital For Oxygen Plant Business?

In the competitive landscape of the oxygen supply industry, implementing the right operational KPIs for oxygen business is essential for measuring efficiency and boosting overall performance. Oxygen Innovations must focus on specific metrics that drive productivity, ensure high-quality output, and streamline operations. Here are the core operational KPIs that are vital for an oxygen plant business:

- Production Efficiency Rate: This KPI measures the ratio of actual oxygen produced to the maximum potential output. A benchmark of over 85% is generally considered effective in the industry.

- Oxygen Quality Compliance Rate: Essential for maintaining standards, this metric tracks the percentage of produced oxygen that meets regulatory specifications. A target of 98% compliance is ideal.

- Energy Consumption Per Unit Produced: Monitoring energy usage is crucial due to high operational costs associated with oxygen production. A standard target is 0.6 kWh per cubic meter of oxygen.

- Equipment Downtime Percentage: This KPI indicates the time production equipment is non-operational due to maintenance or failure. Keeping this below 5% is crucial for minimizing disruption.

- Supply Chain Efficiency Ratio: This KPI measures the effectiveness of the supply chain in delivering the required materials for production. A target ratio of 90% is a good benchmark for timely procurement.

- Employee Productivity Rate: Assessing the actual output per worker is critical. Achieving a rate of 80% units produced per employee per shift is a solid objective.

- Customer Satisfaction Index: A vital metric that gauges customer feedback and satisfaction levels. Striving for a score of 4.5 out of 5 can enhance retention and loyalty.

Tips for Improving Operational KPIs

- Invest in regular training programs for employees to enhance productivity rates and ensure safety in handling equipment.

- Implement preventive maintenance schedules to lower equipment downtime and optimize production efficiency.

- Leverage data analytics tools to continuously monitor and assess key performance indicators in real-time.

Understanding and improving these oxygen plant performance metrics is crucial for Oxygen Innovations in its mission to lead the industry with sustainable and high-quality oxygen production. For additional insights on operational aspects, you can refer to the article here.

How Frequently Does Oxygen Plant Business Review And Update Its KPIs?

In the oxygen plant business, the frequency of reviewing and updating KPI metrics for oxygen plant business is crucial for maintaining operational efficiency and aligning with strategic goals. A robust review process helps identify areas for improvement and ensures that performance metrics stay relevant in a dynamic market.

The recommended frequency for reviewing KPIs typically involves:

- Monthly Reviews: Essential for operational KPIs, such as production efficiency rate and equipment downtime percentage. Monthly evaluations help identify immediate issues and allow for quick corrective actions.

- Quarterly Assessments: Ideal for financial KPIs, including cost per unit of oxygen produced and customer satisfaction index. This frequency enables a thorough analysis of financial health and service quality.

- Annual Comprehensive Review: This in-depth KPI review is necessary to assess long-term goals and strategic alignment, ensuring that all metrics contribute effectively to the overall business objectives.

Additionally, it's essential to be flexible with the review frequency based on specific market conditions. For example, during periods of fluctuating demand or technological advancements, more frequent assessments may be necessary to adapt swiftly to changes. O2 production KPIs like energy consumption per unit produced can be highly variable and may warrant closer monitoring.

Tips for Effective KPI Tracking

- Establish a dashboard for real-time KPI tracking to facilitate ongoing assessments.

- Engage cross-functional teams to bring diverse perspectives during KPI reviews, ensuring comprehensive evaluations.

- Document the outcomes of each review session to track progress and facilitate accountability.

Regularly reviewing and updating core KPI metrics for oxygen plants not only aids in improving operational efficiency but also enhances competitiveness in the industry. By staying proactive and responsive to performance metrics, companies like Oxygen Innovations can ensure they meet the growing demand for high-quality oxygen while maintaining sustainable practices.

According to industry benchmarks, companies that consistently track and update their KPIs can achieve up to a 30% increase in operational efficiency and a 20% reduction in costs. This data underscores the importance of maintaining an agile approach to KPI management to ensure ongoing success in the oxygen production sector.

What Kpis Help Oxygen Plant Business Stay Competitive In Its Industry?

In the rapidly evolving landscape of the oxygen supply industry, having the right KPI metrics for oxygen plant business is essential for maintaining a competitive edge. The ability to track KPIs effectively enables organizations like Oxygen Innovations to respond swiftly to market demands while optimizing operations and enhancing profitability.

Here are some of the key KPIs that can help an oxygen plant stay competitive:

- Production Efficiency Rate: This metric reflects how well the production process converts inputs into outputs. For oxygen plants, a target efficiency rate above 90% is typically sought.

- Cost Per Unit of Oxygen Produced: Keeping this cost low is critical. A competitive oxygen plant aims for a cost reduction of at least 15% over the industry average.

- Oxygen Quality Compliance Rate: Ensuring product quality is non-negotiable. The compliance rate should be at or near 100%. Regular quality assessments must align with industry standards.

- Customer Satisfaction Index: Tracking this index allows companies to gauge customer loyalty and satisfaction. Targeting a score above 85% can significantly enhance client retention.

- Energy Consumption Per Unit Produced: As sustainability becomes increasingly important, monitoring energy use can lead to a reduction of up to 20% in energy costs yearly.

- Supply Chain Efficiency Ratio: An efficient supply chain can provide a competitive edge. A ratio of at least 95% indicates smooth operations from raw materials to product delivery.

- Employee Productivity Rate: High employee productivity directly impacts output and efficiency. Aiming for a 20% increase in productivity can yield significant returns.

- Environmental Impact Score: In today’s eco-conscious market, minimizing impacts is critical. Lowering this score by 10% annually can foster a positive public image and compliance with regulations.

Tips for Implementing KPIs Effectively

- Regularly review and adjust KPIs to reflect changing industry conditions and business strategies.

- Invest in technology that allows for real-time tracking of O2 production KPIs.

- Engage employees in the KPI tracking process to enhance accountability and drive performance.

Additionally, it is critical to perform a financial analysis to understand the profitability aspects of the oxygen plant. According to recent studies, businesses that actively measure and analyze financial KPIs often achieve profit margins exceeding 30% compared to their less vigilant counterparts. Understanding how to calculate KPIs for oxygen plant business helps in recognizing trends, forecasting outcomes, and ultimately driving growth.

By focusing on these essential KPIs for industrial oxygen production, Oxygen Innovations can effectively position itself in the market, ensuring resilience against competition while adapting to ever-evolving demands.

How Does Oxygen Plant Business Align Its KPIs With Long-Term Strategic Goals?

Aligning KPI metrics for oxygen plant business with long-term strategic goals is essential for success in the competitive oxygen supply market. Oxygen Innovations' mission to address the critical shortage of high-quality oxygen requires a well-structured approach in measuring performance. By establishing essential O2 production KPIs, the company can ensure that operational effectiveness and financial health are consistently monitored and improved.

To effectively align KPIs with strategic objectives, Oxygen Innovations focuses on the following core areas:

- Production Efficiency Rate: Tracking this KPI helps assess how effectively assets are utilized, which is paramount for maintaining a cost-effective operation.

- Cost Per Unit of Oxygen Produced: By monitoring this KPI, the company can identify opportunities for cost reductions, ensuring competitive pricing without sacrificing quality.

- Oxygen Quality Compliance Rate: This metric is critical to uphold the facility’s reputation and meet regulatory standards, significantly affecting long-term sustainability goals.

- Energy Consumption Per Unit Produced: Reducing energy usage is not only beneficial for operational efficiency but also aligns with the broader goal of promoting eco-friendly practices.

Real-time assessment and adjustment of these KPIs are crucial. For instance, production plants that aim for an efficiency improvement of at least 5% annually could significantly enhance their profit margins. Moreover, maintaining a customer satisfaction index above 90% can positively impact repeat business and brand loyalty, critical components for long-term growth.

Incorporating these metrics requires regular reviews and recalibrations to ensure alignment with evolving strategic goals. Performance metrics such as employee productivity rates and equipment downtime percentages should be assessed quarterly to keep pace with industry changes.

Tips for Aligning KPIs with Strategic Goals

- Conduct regular KPI reviews to adapt to market conditions or operational changes.

- Integrate financial analysis into KPI tracking for more informed decision-making.

By continuously measuring operational KPIs and adjusting them in alignment with strategic goals, Oxygen Innovations can drive its vision of revolutionizing the oxygen supply industry while fulfilling its commitment to sustainability and reliability. For further insights on financial metrics, exploring materials such as profitability analyses can be beneficial.

What Kpis Are Essential For Oxygen Plant Business’s Success?

For Oxygen Innovations to thrive in the competitive landscape of the oxygen supply industry, it is crucial to focus on key performance indicators (KPIs) that measure success and efficiency. Tracking these KPI metrics for oxygen plant business not only helps in assessing operational capabilities but also aids in financial decision-making.

Here are the core KPIs that are essential for the success of an oxygen plant:

- Production Efficiency Rate: This measures the output of oxygen produced against the maximum potential output, often expressed as a percentage. Successful plants often aim for a rate of over 90%.

- Cost Per Unit of Oxygen Produced: Calculating the total operating costs divided by the number of units produced provides insights into profitability. A benchmark would be maintaining costs below $0.50 per cubic meter of oxygen.

- Oxygen Quality Compliance Rate: This metric tracks the percentage of oxygen produced that meets industry standards. A compliance rate should ideally be above 98% to ensure customer trust and regulatory adherence.

- Customer Satisfaction Index: This is gauged through customer feedback and surveys, with top-performing plants often achieving scores above 85%.

- Energy Consumption Per Unit Produced: By monitoring this KPI, plants can optimize energy usage, aiming for a benchmark of less than 0.6 kWh per cubic meter of oxygen produced.

- Supply Chain Efficiency Ratio: Assessing the efficiency of the supply chain can be achieved by evaluating the total supply chain costs against the revenue generated from oxygen sales. A ratio of 0.5 or lower is desirable.

- Employee Productivity Rate: This indicator measures the output per employee and influences labor costs. Leading oxygen plants target around 1,000 cubic meters per employee per month.

- Equipment Downtime Percentage: Equipment reliability is vital; thus, maintaining downtime below 5% is a sign of a well-functioning facility.

- Environmental Impact Score: This score evaluates the ecological footprint of the oxygen production process. Progressive plants are striving for lower emissions, aiming for a score that reflects minimal environmental impact.

These essential KPIs not only enhance oxygen plant performance metrics but also support the strategic goals of improving operational efficiency and customer satisfaction. By utilizing these KPIs, Oxygen Innovations can effectively measure progress in various areas and align their operations with industry benchmarks.

Tips for Effective KPI Tracking

- Regularly review your KPI metrics to adapt to market changes and operational challenges.

- Utilize data visualization tools to make performance data easily understandable for all stakeholders.

- Set realistic targets based on historical data and industry benchmarks to motivate and guide your team.

Production Efficiency Rate

The Production Efficiency Rate is a critical KPI metric for oxygen plant business operations. It measures the efficiency of oxygen output relative to the resources consumed. In the context of an oxygen plant, this metric reflects how effectively the facility utilizes its equipment, labor, and materials to produce oxygen. By evaluating this rate, Oxygen Innovations can pinpoint operational strengths and weaknesses, providing insights into potential areas for improvement.

To calculate the Production Efficiency Rate, the following formula is commonly used:

Production Efficiency Rate (%) = (Actual Output / Maximum Possible Output) x 100

For an oxygen plant, the actual output could be measured in the number of oxygen units produced per hour, while the maximum possible output is determined by the production capacity of the facility under optimal conditions.

| Year | Actual Output (units) | Maximum Output (units) | Production Efficiency Rate (%) |

|---|---|---|---|

| 2021 | 2,500 | 3,000 | 83.33% |

| 2022 | 2,900 | 3,100 | 93.55% |

| 2023 | 3,000 | 3,200 | 93.75% |

This table illustrates the Production Efficiency Rate over a three-year period for Oxygen Innovations. The increases in efficiency demonstrate the effectiveness of ongoing improvements in operations and technology.

Strong production efficiency is vital for maintaining competitive advantage in the oxygen supply industry. Higher efficiency rates can lead to reduced costs and enhanced quality of service, aligning with the financial and operational KPIs for oxygen business performance.

Tips for Improving Production Efficiency Rate

- Regularly maintain and upgrade equipment to minimize breakdowns and downtimes.

- Implement lean manufacturing techniques to identify and eliminate waste in the production process.

- Continuously train staff on best practices and efficiency-saving techniques.

By closely monitoring the Production Efficiency Rate, Oxygen Innovations can ensure it is meeting the growing demand for high-quality oxygen while fostering sustainable practices. This focus will not only support better financial analysis oxygen plants but also align with the long-term strategic goals of the business.

Additionally, the KPI metrics for oxygen plant business can be enhanced by integrating modern technologies such as IoT and AI, which can provide real-time data analytics for more informed decision-making regarding production processes.

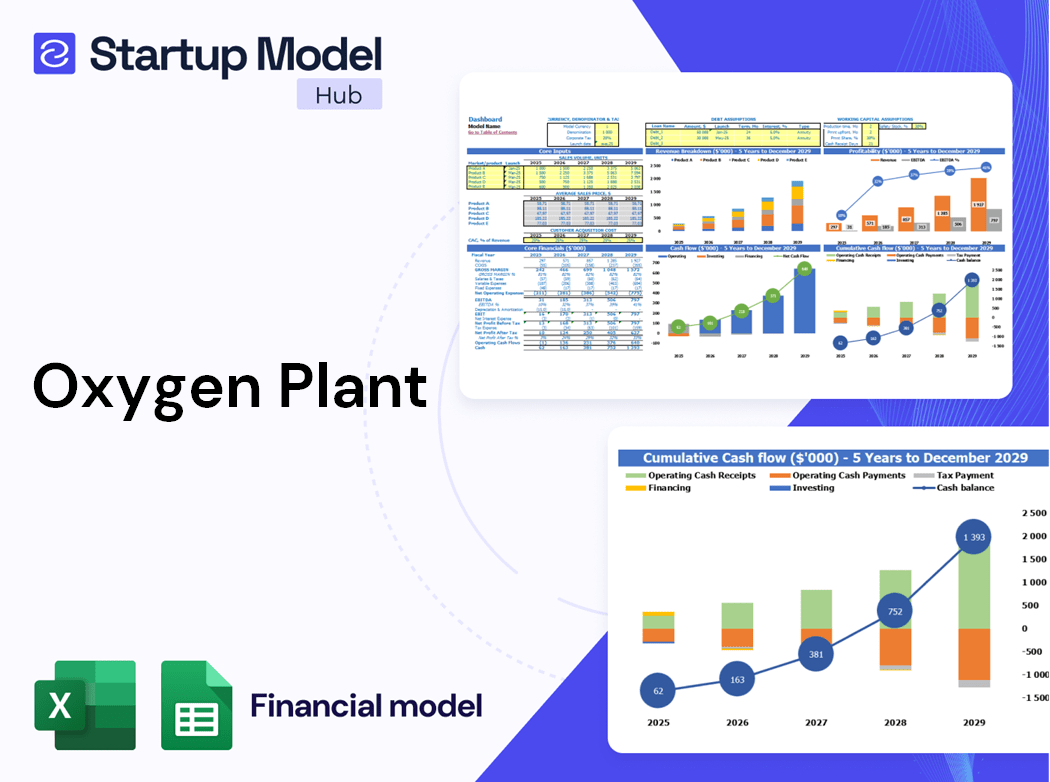

For a comprehensive financial model tailored to the oxygen plant business, including detailed KPI calculations, visit Oxygen Innovations Financial Model.

Cost Per Unit Of Oxygen Produced

One of the fundamental KPI metrics for oxygen plant business is the Cost Per Unit of Oxygen Produced. This metric provides insight into the financial efficiency of an oxygen production facility by measuring the total cost incurred to produce one unit of oxygen, typically expressed in dollars per cubic meter (m³) or per kilogram (kg).

The formula to calculate this KPI is as follows:

| Total Production Costs | Units of Oxygen Produced | Cost Per Unit of Oxygen |

|---|---|---|

| $500,000 | 250,000 m³ | $2.00/m³ |

In this example, if the total production costs amount to $500,000 for producing 250,000 m³ of oxygen, the cost per unit of oxygen produced would be $2.00/m³. This calculation is critical for understanding the economic viability and operational efficiency of the oxygen plant.

Measuring the Cost Per Unit of Oxygen Produced helps identify areas where operational improvements can be made. Below are some factors to consider:

- Raw material costs, including the price of feedstock and any additives used in production.

- Energy consumption, as electricity or gas expenses can significantly impact production costs.

- Labor costs associated with the workforce maintaining operations.

- Equipment maintenance and depreciation, which can affect the overall expenditure.

- Overhead costs such as facility leasing, utilities, and administrative expenses.

By continuously monitoring this KPI, businesses can make informed decisions regarding cost-cutting and efficiency-enhancing measures. For example, an oxygen plant might implement energy-efficient technologies to lower energy costs, thereby reducing the cost per unit of oxygen produced.

Tips for Reducing Cost Per Unit of Oxygen Produced

- Invest in energy-efficient production technologies to decrease overall energy expenses.

- Evaluate supplier contracts regularly to ensure competitive pricing for raw materials.

- Implement predictive maintenance strategies to minimize equipment downtime and reduce repair costs.

- Train employees to enhance efficiency and reduce labor-related costs.

In the context of the oxygen plant business—such as Oxygen Innovations—the goal is not only to meet the growing demand for high-quality oxygen across various sectors but also to do so sustainably and financially efficiently. Therefore, tracking this KPI, alongside other operational KPIs for oxygen business, is crucial for maintaining a competitive edge in the market.

Industry benchmarks suggest that leading oxygen plants achieve a cost per unit of oxygen produced ranging from $1.50 to $2.50 per m³, depending on regional factors and operational efficiencies. This range provides a solid reference point for evaluating performance against industry standards.

For those interested in delving deeper into financial analysis and operational strategies, tools like the Oxygen Plant Financial Model are invaluable resources. They assist in comprehensively understanding and tracking the KPIs for industrial oxygen production, ultimately guiding decisions that enhance productivity and sustainability. For more information, visit Oxygen Plant Financial Model.

Oxygen Quality Compliance Rate

In the oxygen plant industry, maintaining a high Oxygen Quality Compliance Rate is critical for ensuring the safety and satisfaction of customers. This metric measures the percentage of oxygen produced that meets established quality standards, such as ISO or ASTM specifications. A high compliance rate not only reflects the effectiveness of production processes but also helps in building customer trust and loyalty.

The formula to calculate the Oxygen Quality Compliance Rate is straightforward:

Oxygen Quality Compliance Rate (%) = (Number of Compliant Oxygen Units / Total Units Produced) x 100

For example, if an oxygen plant produced 10,000 units of oxygen and 9,800 of those units met quality standards, the compliance rate would be:

Oxygen Quality Compliance Rate = (9,800 / 10,000) x 100 = 98%

This means that an impressive 98% of the produced oxygen complies with quality regulations, significantly enhancing the plant's credibility and operational efficiency.

To achieve a high Oxygen Quality Compliance Rate, oxygen plants need to focus on several factors:

- Strict adherence to quality control processes.

- Regular audits and compliance checks.

- Employee training and awareness on quality standards.

- Investment in advanced monitoring technologies.

In a competitive landscape, where the demand for high-quality oxygen is on the rise, oxygen plants must prioritize their compliance rates not just to meet regulatory standards but also to differentiate themselves from competitors. Research indicates that oxygen plants with a compliance rate above 95% can ensure better customer retention and operational efficiency, resulting in an overall boost to financial performance.

| Compliance Rate (%) | Customer Satisfaction (%) | Market Share (%) |

|---|---|---|

| 98 | 95 | 25 |

| 92 | 88 | 15 |

| 85 | 80 | 10 |

Investing in maintaining and improving the Oxygen Quality Compliance Rate can lead to enhanced operational KPIs and overall success of the oxygen plant. For those looking to delve deeper into the financial implications and detailed modeling, visit Oxygen Innovations' financial model for comprehensive insights.

Tips for Improving Oxygen Quality Compliance Rate

- Implement advanced quality monitoring systems to detect deviations in real-time.

- Regularly update training programs to keep staff informed about the latest quality regulations.

- Conduct frequent internal audits to identify areas for improvement.

Ultimately, tracking the Oxygen Quality Compliance Rate is integral to achieving the financial KPIs for oxygen plants. By ensuring high-quality output, oxygen plants can significantly improve their market positioning while also optimizing their operational efficiency.

Customer Satisfaction Index

The Customer Satisfaction Index (CSI) is a crucial KPI metric for oxygen plant businesses, particularly for companies like Oxygen Innovations that aim to provide high-quality products while ensuring customer loyalty and retention. Measuring customer satisfaction allows businesses to understand their customer base better and identify areas for improvement in service and product quality.

In the oxygen supply industry, maintaining a high CSI is essential due to the critical nature of the product. Customers rely on a continuous and reliable supply of oxygen, especially in healthcare, industrial, and various other sectors. A satisfied customer is likely to return and recommend the service to others, positively impacting sales and market reputation.

| KPI Metric | Benchmark | Importance |

|---|---|---|

| Customer Satisfaction Index | 75% or higher | Indicates product quality and service effectiveness |

| Net Promoter Score (NPS) | 50 or higher | Measures customer loyalty and potential for referrals |

| Customer Retention Rate | 80% or higher | Indicates the ability to maintain clientele |

To calculate the Customer Satisfaction Index effectively, oxygen plants can employ various methods, including surveys, feedback forms, and customer interviews. A straightforward formula can be used:

CSI = (Number of Satisfied Customers / Total Customers Surveyed) x 100

For instance, if 80 out of 100 surveyed customers express satisfaction with the oxygen quality and delivery service, the CSI would be:

CSI = (80 / 100) x 100 = 80%

Tips for Improving Customer Satisfaction

- Conduct regular customer surveys to gather feedback on product quality and service.

- Address complaints promptly to demonstrate commitment to customer care.

- Implement a loyalty program to reward returning customers.

Tracking the CSI alongside other operational KPIs will provide a comprehensive view of the overall performance of the oxygen plant business. This not only helps in identifying specific areas that need attention but also aids in aligning operational efforts with financial KPIs for oxygen plant performance metrics.

The importance of tracking oxygen plant KPIs cannot be overstated, as it provides insights that significantly impact the overall effectiveness and competitiveness of the business in the industrial oxygen production landscape.

To explore a comprehensive approach to financial modeling for oxygen plants, consider checking out the detailed financial model available at Oxygen Plant Financial Model.

Energy Consumption Per Unit Produced

The Energy Consumption Per Unit Produced is a pivotal operational KPI metric for an oxygen plant business. This metric measures the amount of energy consumed to produce a single unit of oxygen, reflecting the efficiency of the production process. In the context of Oxygen Innovations, optimizing this KPI is crucial to both financial performance and environmental sustainability.

To calculate this KPI, the following formula can be utilized:

| Energy Consumption (kWh) | Oxygen Produced (units) | Energy Consumption Per Unit (kWh/unit) |

|---|---|---|

| 1500 kWh | 1000 units | 1.5 kWh/unit |

In this example, the oxygen plant consumed 1500 kWh to produce 1000 units of oxygen, resulting in an energy consumption rate of 1.5 kWh/unit. This figure can serve as a benchmark for performance assessments.

Reducing energy consumption not only minimizes operational costs but also enhances the sustainability profile of the oxygen plant, aligning with the growing demand for eco-friendly manufacturing practices. The target for many oxygen plants is to achieve an energy consumption rate below 2 kWh/unit, which signifies efficient energy usage.

Tips for Managing Energy Consumption

- Regularly monitor energy usage with advanced metering systems to identify inefficiencies.

- Implement energy recovery systems to reuse energy where possible.

- Invest in energy-efficient equipment and technologies to lower consumption rates.

By focusing on minimizing energy consumption, Oxygen Innovations can not only reduce costs but also enhance its competitiveness in the oxygen supply industry. According to recent industry statistics, optimizing energy usage can lead to savings of up to 30% in production costs, which significantly impacts the bottom line.

A practical approach is to benchmark against industry standards, where successful oxygen plants maintain an energy consumption rate of 1.2 kWh/unit. This can provide a clear target for Oxygen Innovations, helping to drive improvements in operational efficacy.

The importance of tracking this KPI cannot be overstated. Effective KPI metrics for oxygen plant business operations enable managers to make data-driven decisions that align with long-term strategic goals. It's imperative that Oxygen Innovations continuously evaluates its energy consumption metrics not only to enhance productivity but also to affirm its position as a sustainable leader in the oxygen production industry.

In summary, maintaining a keen focus on energy consumption per unit produced allows Oxygen Innovations to improve its operational efficiency while contributing positively to environmental stewardship.

Supply Chain Efficiency Ratio

The Supply Chain Efficiency Ratio is a critical metric for the oxygen plant business, particularly for a company like Oxygen Innovations, which aims to meet the rising demand for high-quality oxygen while promoting sustainability. This KPI helps assess how effectively the supply chain is operating by comparing the cost of goods sold (COGS) against the total revenue generated from oxygen sales.

To calculate the Supply Chain Efficiency Ratio, use the following formula:

| Formula | Description |

|---|---|

| Supply Chain Efficiency Ratio = Total Revenue / Cost of Goods Sold | This ratio indicates how much revenue is generated for every unit of cost incurred in producing oxygen. |

For instance, if Oxygen Innovations generates $1,000,000 in revenue and incurs $600,000 in COGS, the Supply Chain Efficiency Ratio would be:

| Calculation | Value |

|---|---|

| Supply Chain Efficiency Ratio | 1,000,000 / 600,000 = 1.67 |

This means that for every dollar spent on production, Oxygen Innovations generates $1.67 in revenue, signifying a highly efficient supply chain.

Monitoring the Supply Chain Efficiency Ratio is essential for several reasons:

- Cost Management: Understanding this ratio helps identify areas where costs can be reduced without compromising quality.

- Resource Allocation: It aids in making informed decisions regarding investments in resources and technologies that enhance efficiency.

- Strategic Planning: A high ratio reflects a competitive advantage, allowing Oxygen Innovations to strategize for growth and expansion in the market.

Tips for Improving Supply Chain Efficiency Ratio

- Implement technology solutions such as inventory management systems to optimize stock levels.

- Negotiate better terms with suppliers to reduce COGS.

- Enhance logistics operations to ensure timely delivery and minimize operational delays.

Furthermore, leveraging data analytics to assess performance against benchmarks can significantly aid in understanding how well the oxygen plant is performing compared to industry standards. For example, the average Supply Chain Efficiency Ratio in the industrial oxygen production sector typically hovers around 1.5 to 2.5. By aligning with or exceeding these benchmarks, Oxygen Innovations can validate its operational effectiveness and enhance its market position.

In summary, the Supply Chain Efficiency Ratio serves as a foundational metric within the broader framework of KPIs for the oxygen plant business. By continually monitoring this efficiency ratio, Oxygen Innovations not only reinforces its commitment to operational excellence but also strategically positions itself against competitors in the oxygen supply industry.

Employee Productivity Rate

The Employee Productivity Rate is a crucial KPI metric for oxygen plant business, such as Oxygen Innovations. It assesses how effectively employees contribute to the overall production of oxygen, which directly impacts operational efficiency and profitability. By measuring this rate, organizations can identify performance gaps and implement strategies for improvement, ultimately leading to increased O2 production.

Employee productivity in an oxygen plant can be calculated using the formula:

Employee Productivity Rate = Total Oxygen Produced / Total Employee Hours Worked

In an industry where efficiency is key, benchmarking employee productivity against industry standards can help identify areas needing enhancement. For instance, an oxygen plant with an average output of 500 tons per month and a total of 1,600 hours worked would calculate as follows:

| Metric | Value |

|---|---|

| Total Oxygen Produced (tons) | 500 |

| Total Employee Hours Worked (hours) | 1,600 |

| Employee Productivity Rate (tons/hour) | 0.3125 |

According to industry benchmarks, a typical productivity rate for oxygen plants may range from 0.3 to 0.5 tons per hour. Therefore, maintaining a rate closer to the upper end of this range not only signifies operational efficiency but also fosters a competitive edge. Enhancing employee productivity can significantly reduce the cost per unit of oxygen produced and ultimately improve the plant's overall financial performance.

Tips for Enhancing Employee Productivity in Oxygen Plants

- Implement regular training and skill development programs to empower employees.

- Utilize advanced technology and automation to reduce manual tasks and errors.

- Establish clear performance goals and provide real-time feedback to motivate staff.

Another aspect of measuring the Employee Productivity Rate involves assessing the impact of employee satisfaction on productivity. Engaged employees typically exhibit higher efficiency, leading to better overall performance for the oxygen plant. Surveys and assessments can be utilized to gauge employee morale and pinpoint areas that may require attention.

By closely monitoring this KPI, Oxygen Innovations can align its workforce's capabilities with the company's long-term strategic goals. For example, if the target is to increase production by 20% in the next fiscal year, understanding the current productivity rate can help benchmark necessary improvements.

| Year | Target Increase in Production | Required Productivity Rate (tons/hour) |

|---|---|---|

| 2023 | 20% | 0.375 |

| 2024 | 25% | 0.390625 |

In summary, the Employee Productivity Rate stands out as a vital operational KPI that oxygen plants like Oxygen Innovations must track closely. By doing so, they can ensure a more efficient production process, reduce costs, and foster a workplace environment conducive to sustained growth and success in the competitive oxygen market.

For businesses looking to develop a solid financial plan for their oxygen plant, consider exploring detailed templates such as the one available at Oxygen Plant Financial Model.

Equipment Downtime Percentage

In the oxygen plant business, tracking the Equipment Downtime Percentage is crucial for assessing operational efficiency and overall performance. Equipment downtime refers to the time when production equipment is not operational due to maintenance, malfunctions, or other issues. This metric directly impacts the ability to meet production targets and fulfill customer demand.

The formula to calculate Equipment Downtime Percentage is as follows:

| Downtime (in hours) | Total Available Production Time (in hours) | Equipment Downtime Percentage |

| 40 hours | 1000 hours | (40 / 1000) 100 = 4% |

A lower Equipment Downtime Percentage signifies that an oxygen plant is executing production efficiently, while a higher percentage indicates potential inefficiencies that can lead to increased costs and reduced competitiveness within the market.

According to industry benchmarks, an optimal Equipment Downtime Percentage for well-run oxygen plants typically ranges between 2% and 5%. However, many facilities struggle to maintain this level, with some reporting downtime percentages as high as 10% or more. This not only hampers production but also increases operational costs significantly.

Tips to Reduce Equipment Downtime

- Implement a proactive maintenance schedule to prevent unexpected failures.

- Invest in high-quality equipment and technology to minimize breakdowns.

- Train staff thoroughly on equipment operation to avoid operator errors.

Tracking this KPI metric allows oxygen plant operators to identify trends and implement strategies that improve performance over time. Furthermore, regular reviews of downtime metrics will help align the plant’s operational goals with its long-term strategic objectives.

In the context of the oxygen supply industry, companies like Oxygen Innovations are focusing on minimizing downtime to enhance production capabilities and ensure reliability in their oxygen supply chain. By utilizing sophisticated monitoring systems, they can quickly respond to equipment issues, thus improving their overall O2 production KPIs.

Ultimately, understanding the impact of Equipment Downtime Percentage on oxygen plant performance metrics is essential for driving efficiency and maintaining competitiveness in this growing industry. For detailed financial planning and KPI tracking specific to oxygen plants, resources like the Oxygen Plant Financial Model can provide valuable insights.

Environmental Impact Score

The Environmental Impact Score is a critical KPI metric for oxygen plant businesses, especially for companies like Oxygen Innovations, which aim to integrate sustainability into their operations. This score evaluates how the production processes affect the environment, assessing aspects such as emissions, waste management, and resource consumption. By effectively measuring their environmental footprint, oxygen plants can ensure compliance with regulatory standards and promote eco-friendly practices that resonate with today’s environmentally conscious consumers.

To calculate the Environmental Impact Score, oxygen plants can utilize several key parameters:

- Greenhouse Gas Emissions (GHG) per unit of oxygen produced

- Waste generated (in kilograms) per unit of oxygen produced

- Water usage (in liters) per unit of oxygen produced

For example, if an oxygen plant produces 10,000 units of oxygen and generates 200 kg of waste, the waste generation KPI would be calculated as follows:

Waste Generation KPI = Total Waste (kg) / Total O2 Produced (units)

Waste Generation KPI = 200 kg / 10,000 units = 0.02 kg/unit

To benchmark the Environmental Impact Score, consider the following industry standards:

| Parameter | Standard Benchmark | Current Performance |

|---|---|---|

| GHG Emissions (kg/unit) | 0.1 kg/unit | 0.08 kg/unit |

| Waste Generation (kg/unit) | 0.03 kg/unit | 0.02 kg/unit |

| Water Usage (liters/unit) | 50 liters/unit | 45 liters/unit |

Improving the Environmental Impact Score not only aids in regulatory compliance but also boosts the company’s reputation, attracting customers who prioritize sustainability. It also opens doors to potential grants and incentives aimed at environmentally-friendly businesses.

Tips for Improving Your Environmental Impact Score

- Conduct regular environmental audits to identify areas for improvement.

- Invest in technology that reduces emissions and waste.

- Engage employees in sustainability initiatives to foster a culture of environmental responsibility.

Incorporating the Environmental Impact Score into the overall KPI metrics for oxygen plant business will help align operations with long-term strategic goals while ensuring a balance between productivity and eco-conscious practices. This approach is essential for Oxygen Innovations to maintain competitiveness in the industry and to appeal to a broader market.

To further refine your strategy and monitor your oxygen plant’s performance metrics, exploring management tools tailored for the oxygen production industry can significantly enhance KPI tracking. Consider accessing resources such as oxygen plant financial models for systematic analysis and comprehensive insights.