Related Blogs

Are you curious about the top nine startup costs associated with launching an oxygen plant business? Understanding these essential expenses can pave the way for your entrepreneurial success. From equipment purchases to licensing fees, each cost plays a pivotal role in your financial planning. Ready to dive deeper? Explore a comprehensive business plan to help you navigate these challenges effectively at this link.

How Much Does It Cost To Start An Oxygen Plant Business?

Starting an oxygen plant business involves a range of startup costs that can significantly impact your financial planning. The total costs can vary widely depending on the scale of the operation, location, and technology used. On average, the cost to start an oxygen plant can range from $500,000 to over $2 million, depending on various factors.

Here are some of the primary components that contribute to the overall oxygen plant startup costs:

- Equipment Purchase and Installation: This is one of the largest expenses, often accounting for 40-50% of the total startup costs. Essential equipment includes oxygen generators, compressors, and storage tanks.

- Facility Construction or Renovation: Depending on the location, setting up a suitable facility can cost between $100,000 and $1 million. This includes costs for land acquisition, construction, and renovations to meet operational needs.

- Licensing and Permits: Compliance with local, state, and federal regulations is crucial. The licensing requirements for oxygen plants can range from $10,000 to $50,000 depending on jurisdiction.

- Initial Raw Materials and Supplies: The cost of raw materials for oxygen production can range from $20,000 to $100,000, depending on the production method and scale.

- Technology and Software Development: Implementing advanced technology for efficient production can cost anywhere from $50,000 to $200,000.

- Safety and Compliance Upgrades: Ensuring safety standards can lead to costs of $30,000 to $100,000 for necessary equipment and training.

- Marketing and Branding Costs: Initial marketing efforts to establish a brand presence may require an investment of $10,000 to $50,000.

- Research and Development Expenses: Developing innovative oxygen solutions may necessitate a budget of $20,000 to $100,000.

- Insurance and Bonding Costs: Insurance needs for oxygen businesses can vary, but expect to allocate at least $5,000 to $20,000 for comprehensive coverage.

When considering these costs, it's essential to conduct thorough financial planning. For instance, if you are aiming for a cost-effective oxygen plant setup, consider exploring oxygen plant funding options that may help mitigate initial expenses.

Tips for Reducing Startup Costs

- Consider leasing equipment instead of purchasing it outright to lower initial costs.

- Explore government grants and incentives for sustainable businesses to help with funding.

- Network with industry professionals to find cost-effective suppliers for raw materials and equipment.

By carefully analyzing and planning for these oxygen business expenses, you can create a more accurate budget and improve your chances of establishing a successful oxygen production business.

Is It Possible To Start An Oxygen Plant Business With Minimal Investment?

Starting an oxygen plant business, like any industrial venture, requires a careful assessment of oxygen plant startup costs. However, it is feasible to initiate this type of business with a minimal investment by strategically reducing costs and utilizing effective financial planning strategies.

One major component in minimizing the cost to start an oxygen plant is selecting the right scale for the operation. Micro or small-scale oxygen production units can significantly lower initial capital requirements. For instance, a small-scale operation may require anywhere from $50,000 to $150,000, whereas larger installations could necessitate upwards of $1 million.

Here are some strategies that can be employed to reduce startup expenses:

Cost-Effective Strategies for Starting an Oxygen Plant

- Opt for used equipment instead of new, which can lower oxygen plant equipment expenses by as much as 30% to 50%.

- Consider leasing space rather than constructing a new facility, potentially saving significant facility construction costs.

- Utilize local suppliers for raw materials to cut down on transportation costs, which can help in raw material costs for oxygen production.

- Engage in crowdfunding or explore oxygen plant funding options to gather financial resources without high upfront investments.

Additionally, understanding the licensing requirements for oxygen plants can save time and resources. A thorough research into local regulations may reveal opportunities for expedited or reduced fees based on business size or environmental impact.

Moreover, businesses can explore innovative technology that lowers operational costs. Investing in energy-efficient systems can pay off in the long run by reducing the operational costs of an oxygen plant by as much as 20% to 40% within the initial years.

For those still curious about the feasibility of an oxygen production business on a budget, essential financial planning should focus on cost breakdown for oxygen plant setup. By creating a well-structured budget, entrepreneurs can prioritize spending and seek alternatives that align with their financial capabilities.

In short, while the initial investment in starting an oxygen plant business can seem daunting, adopting a strategic approach to cost management allows for a more accessible entry into the market. For further insights on profitability and essential metrics, you might find this resource helpful: Oxygen Plant Profitability.

Which Costs Can Be Reduced For An Oxygen Plant Business?

Starting an oxygen production business requires careful financial planning due to its numerous startup costs. However, there are various strategies to minimize these expenses without compromising quality or compliance. Here are key areas where costs can be effectively reduced:

1. Equipment Purchase and Installation

Investing in new equipment can be a significant portion of the total costs to start an oxygen plant. Consider these tips:

Tips to Reduce Equipment Costs

- Explore second-hand or refurbished equipment options, which can offer substantial savings (up to 30-50%).

- Negotiate with suppliers for discounts or financing options that reduce upfront investment.

2. Facility Construction or Renovation

The expenses associated with building or renovating a facility are often high. To mitigate these costs:

Cost-Saving Strategies for Facilities

- Opt for leasing a facility instead of purchasing, which can save 20-40% in initial investment.

- Utilize modular construction techniques, which tend to be quicker and more cost-effective.

3. Licensing and Permits

Licensing requirements for oxygen plants can vary greatly by region. Consider the following:

Ways to Minimize Licensing Costs

- Research and understand local regulations to avoid unnecessary fees.

- Utilize consultants for licensing processes as a one-time cost that can save on long-term delays and fines.

4. Initial Raw Materials and Supplies

Raw material costs for oxygen production can fluctuate, impacting initial budgets. To counter this:

Strategies for Raw Material Savings

- Establish long-term contracts with suppliers to lock in lower prices.

- Buy in bulk where possible, as this can reduce costs by 10-15%.

5. Technology and Software Development

Technology costs in oxygen production, including specialized software, can add up. To reduce these expenses:

Cost-Effective Technology Solutions

- Consider off-the-shelf software rather than custom solutions which can be significantly cheaper.

- Use open-source technology solutions where applicable to eliminate licensing fees.

6. Safety and Compliance Upgrades

Safety compliance costs for oxygen plants are non-negotiable but can be optimized:

Ways to Optimize Compliance Costs

- Invest in training programs for staff to avoid costly compliance fines down the road.

- Regularly review safety practices to ensure they meet current standards, which can minimize the risk of expensive penalties.

7. Marketing and Branding Costs

Marketing costs for an oxygen business can be substantial but are crucial for growth:

Effective Marketing Cost Management

- Utilize digital marketing strategies, which can be significantly more cost-effective compared to traditional methods.

- Leverage social media platforms for free promotional opportunities.

8. Research and Development Expenses

Research expenses for oxygen plants can be reduced by:

Cost-Effective R&D Approaches

- Collaborate with academic institutions for shared resources and funding opportunities.

- Apply for grants specific to sustainability and innovation in the oxygen industry.

9. Insurance and Bonding Costs

Insurance needs for oxygen businesses should be approached strategically:

Insurance Cost Reduction Tips

- Shop around for insurance providers to compare policies and prices.

- Implement comprehensive safety training to potentially lower premiums.

By focusing on these areas and implementing the relevant strategies, startups like Oxygen Innovations can effectively manage their startup costs and allocate their investment in oxygen plant operations more efficiently.

Examples of Startup Budgets for Oxygen Plant Businesses

Embarking on the journey of starting an oxygen production business involves careful financial planning and a clear understanding of the expected costs. Below are some illustrative examples of startup budgets tailored for an oxygen plant business. These examples will help you gauge the necessary investment in various segments to successfully launch your venture.

Sample Budget Breakdown

A typical budget for an oxygen plant startup may encompass the following major expenses, along with rough estimates based on industry standards:

- Equipment Purchase and Installation: $500,000 to $1,000,000

- Facility Construction or Renovation: $300,000 to $700,000

- Licensing and Permits: $10,000 to $50,000

- Initial Raw Materials and Supplies: $50,000 to $100,000

- Technology and Software Development: $20,000 to $100,000

- Safety and Compliance Upgrades: $30,000 to $70,000

- Marketing and Branding Costs: $15,000 to $50,000

- Research and Development Expenses: $25,000 to $150,000

- Insurance and Bonding Costs: $5,000 to $15,000

This preliminary budget totals anywhere from $1,005,000 to $2,235,000, depending on the scale and location of the operation. Each of these costs can fluctuate based on varying factors like equipment specifications and facility requirements.

Real-Life Statistical Data

According to data collected from industry reports, the average cost to start an oxygen plant can vary significantly, often influenced by technology choices and local market conditions. For instance, an advanced facility emphasizing sustainability may require a higher upfront investment compared to a basic production unit. It is essential for potential investors to analyze these figures and tailor their financial planning strategies accordingly.

Tips to Reduce Startup Costs

- Engage in modular equipment purchasing to ease initial financial burdens.

- Consider leasing facilities instead of purchasing outright, minimizing upfront costs.

- Leverage government grants or subsidies aimed at sustainable industries to offset expenses.

Proactive financial planning can play a pivotal role in securing funding and optimizing operational costs of oxygen plant. Resources such as industry benchmarks can provide valuable insights for potential entrepreneurs aiming to set realistic financial goals.

How to Secure Enough Funding to Start an Oxygen Plant Business?

Securing sufficient funding for an oxygen plant business can be a complex endeavor, given the significant startup costs associated with the oxygen production industry. On average, the total investment to start an oxygen plant ranges from $500,000 to $5 million, depending on the scale and technology involved. Understanding the various funding options available is essential for turning your business idea, like Oxygen Innovations, into a reality.

To successfully finance your oxygen plant startup costs, consider the following funding options:

- Self-Funding: Using personal savings or assets can be the quickest way to secure funds, allowing for greater control over the business.

- Bank Loans: Traditional bank loans typically cover a significant portion of initial capital needs, but require a solid business plan and collateral.

- Venture Capital: Attracting venture capitalists can provide substantial funding, especially if your business plan emphasizes sustainable practices and innovative technologies.

- Government Grants and Subsidies: Many governments offer grants for innovative green technologies. Research local programs that may support your oxygen production business.

- Crowdfunding: Platforms such as Kickstarter or Indiegogo allow you to raise small amounts of money from a large number of people, which can be particularly useful for community-backed projects.

- Angel Investors: Angel investors often look to support promising startups, particularly in sectors with a social impact, like oxygen supply.

When planning your financial strategy, it is crucial to prepare a detailed business plan that outlines projected costs, such as:

- Oxygen plant installation costs

- Raw material costs for oxygen production

- Licensing and permits required for operation

Tips for Securing Funding

- Create a comprehensive business plan with clear financial projections, highlighting the operational costs of your oxygen plant.

- Network with industry professionals to gain insights and introductions to potential investors.

According to industry benchmarks, a well-prepared funding request can increase your chances of securing investment by up to 70%. Be ready to demonstrate the potential return on investment for your oxygen plant business.

To further assist in your financial planning, resources such as this article can provide valuable insights into oxygen plant funding options and strategies.

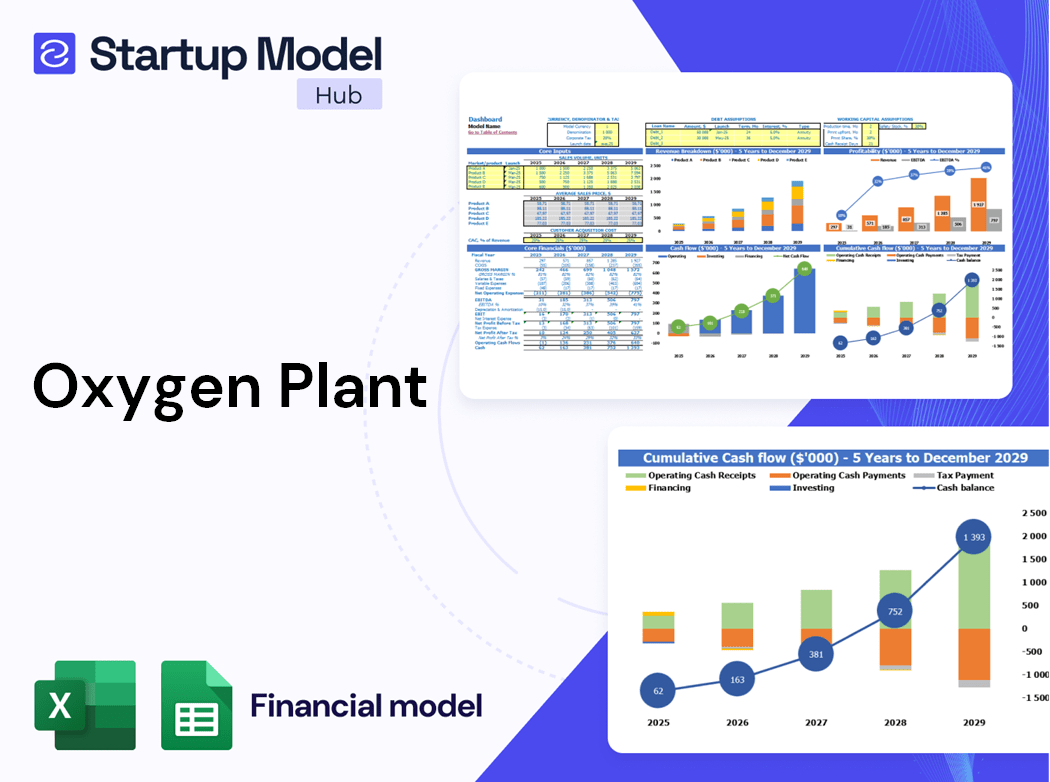

How to Use the Financial Plan for Your Oxygen Plant Business?

Creating a comprehensive financial plan is crucial for the success of your oxygen plant startup. This plan not only outlines your expected expenses and revenues but also serves as a roadmap for managing your financial resources effectively. A well-structured financial plan can help you understand the costs associated with starting an oxygen plant, including the oxygen plant startup costs, equipment, operational costs, and more.

When developing your financial plan, consider the following key components:

- Cost Estimation: Start with identifying the cost to start an oxygen plant, including equipment purchase and installation, facility construction, and raw material costs for oxygen production.

- Funding Sources: Explore various oxygen plant funding options such as loans, grants, or investors. Knowing your funding sources will help you cover initial operational costs.

- Break-even Analysis: Determine how long it will take before you start making a profit. This metric is critical to gauge the sustainability of your oxygen production business.

- Cash Flow Projections: Create cash flow projections for at least the first three years. This helps in understanding your liquidity needs, ensuring you have enough cash to handle day-to-day operations.

- Marketing Budget: Budget for marketing costs related to your oxygen business, as effective marketing is essential for attracting customers in a competitive market.

- Operational Costs: Include expenses such as safety compliance costs for oxygen plants and insurance needs for oxygen businesses.

Tips for Effective Financial Planning

- Regularly update your financial plan to reflect any changes in operational costs or market conditions.

- Utilize financial modeling templates to project future revenues and costs accurately; resources like this one can be very helpful: Oxygen Plant Financial Model.

- Consult with industry experts to enhance your understanding of oxygen production business costs and potential pitfalls.

In order to successfully navigate the complex landscape of starting an oxygen plant business, it is essential to utilize your financial plan not only as a tool for initial setup but as a dynamic guide that evolves with your business. The clearer your financial plan, the smoother your journey toward establishing a profitable and sustainable oxygen plant will be.

What Are The Expenses To Start An Oxygen Plant Business?

Starting an oxygen plant is a significant endeavor that requires careful financial planning. The cost to start an oxygen plant can vary considerably based on numerous factors, including location, technology, and scale of operation. Here are the primary expenses you can expect:

Equipment Purchase and Installation

The most substantial part of your budget will likely go towards oxygen plant equipment expenses. Quality equipment is essential for efficient oxygen production. Depending on the technology you choose—cryogenic distillation or pressure swing adsorption—the initial cost can range from $500,000 to $2 million. Installation costs may add another 10% to 20% to this figure.

Facility Construction or Renovation

If you are not leasing an existing facility, you will need to invest in construction or renovation costs. This can vary widely based on location, size, and the complexity of your operation, ranging from $250,000 to over $1 million.

Licensing and Permits

Navigating the licensing requirements for oxygen plants is crucial. Expect to allocate between $5,000 and $50,000 for necessary permits and licenses, as these can vary significantly by state and country.

Initial Raw Materials and Supplies

Initial inventory of raw materials—such as feedstock—will contribute to your startup costs. Depending on your production capacity, you might need to invest around $20,000 to $100,000 initially in raw material costs for oxygen production.

Technology and Software Development

In this technology-driven sector, integrating technology costs in oxygen production is vital. Investing in software for operational management can cost between $15,000 and $100,000, depending on the complexity.

Safety and Compliance Upgrades

To ensure safety and regulatory compliance, allocating funds for safety equipment and compliance upgrades is essential. This could range from $10,000 to $75,000, depending on the required standards.

Marketing and Branding Costs

Launching your product requires attention to marketing costs for your oxygen business. Budgeting between $5,000 and $50,000 for initial marketing efforts can help establish your brand in the market.

Research and Development Expenses

Investing in research expenses for oxygen plants is critical to staying competitive. Budgeting around $20,000 to $200,000 can provide you with the necessary insights to innovate effectively.

Insurance and Bonding Costs

Finally, securing insurance needs for oxygen businesses is paramount. Depending on your coverage requirements, you may spend between $10,000 and $30,000 annually.

Tips for Reducing Startup Costs

- Consider leasing equipment instead of purchasing it outright to minimize upfront expenses.

- Negotiate terms with suppliers for raw materials to optimize initial cash flow.

- Adopt a phased approach to construction, starting with essential facilities before expanding.

Overall, the investment in an oxygen plant can range from a few hundred thousand to several million dollars. A detailed analysis of these oxygen business expenses is vital for successful financial planning and securing funding options. By efficiently managing these costs, you can set a strong foundation for your oxygen production business. For more insights, you can refer to comprehensive guides on budgeting and expenses in the oxygen plant industry.

Equipment Purchase and Installation

When embarking on an oxygen plant business like Oxygen Innovations, understanding the equipment purchase and installation costs is crucial for effective financial planning. The cost to start an oxygen plant largely hinges on the machinery required to produce oxygen efficiently and safely. Key equipment includes oxygen generators, purification systems, compression units, and storage tanks.

On average, the oxygen plant equipment expenses can range from **$500,000** to **$2 million**, depending on the scale of production and the technology used. To give a clearer picture, here’s a breakdown of typical equipment costs:

| Equipment Type | Estimated Cost (in USD) | Purpose |

|---|---|---|

| Oxygen Generator | $200,000 - $1,000,000 | Production of medical and industrial-grade oxygen |

| Storage Tanks | $50,000 - $200,000 | Safe storage of produced oxygen |

| Purification System | $100,000 - $300,000 | Ensures high-quality output and safety compliance |

| Compression Unit | $50,000 - $100,000 | Compression of oxygen for transport and storage |

Once the equipment is acquired, the installation costs for the oxygen plant must be factored in. Expert installation is necessary to ensure safety standards are met and to minimize downtime. Installation services can add an additional **20%** to the total equipment costs.

To safeguard your investment, consider these tips while planning for your oxygen production business costs:

Cost-Saving Tips for Equipment Purchase

- Research multiple suppliers and compare prices to ensure you get the most competitive rates.

- Consider leasing equipment if starting capital is limited—this can significantly cut initial expenses.

- Opt for pre-owned or refurbished machinery that meets operational standards to reduce costs.

In addition to equipment expenditures, initial raw material costs for oxygen production (such as ambient air for air separation technologies) must also be accounted for in your oxygen business expenses. Though these costs are relatively low, they are essential for maintaining a steady production flow.

When considering the operational costs of the oxygen plant, ongoing maintenance of equipment will be pivotal to ensure longevity and reliability. Regular checks and compliance with safety regulations can help mitigate unforeseen expenses in the long run.

Understanding the licensing requirements for oxygen plants is also crucial, as the permitting process can be time-consuming and costly if not planned properly. Legal and safety compliance costs can amount to **$10,000** to **$100,000**, depending on local regulations.

Ultimately, having a robust financial plan that includes all equipment purchase and installation costs will pave the way for a successful launch and operation. For more insights and detailed financial modeling specific to the oxygen plant startup costs, visit here.

Facility Construction or Renovation

When embarking on an oxygen plant business, one of the most significant startup costs is the facility construction or renovation. This cost can vary greatly depending on several factors, including location, size, and the specific requirements for safety and compliance regulations in the oxygen production industry. It's crucial to prepare a detailed budget to ensure that all aspects of facility establishment are covered.

The typical cost to start an oxygen plant includes expenses related to the construction of new facilities or renovation of existing structures to meet industry standards. According to industry estimates, construction costs can range from $100 to $300 per square foot based on the complexity of the facility and location.

| Facility Type | Average Cost per Square Foot | Total Estimated Cost (1,000 sq. ft.) |

|---|---|---|

| New Construction | $200 - $300 | $200,000 - $300,000 |

| Renovation of Existing Facility | $100 - $200 | $100,000 - $200,000 |

In addition to standard building costs, other essential considerations include:

- Safety Compliance Costs: Modifications may be necessary to ensure the facility meets safety regulations, which can add an additional 10-20% to your overall construction budget.

- Technology Installation: Integrating advanced equipment for oxygen production can increase initial costs, with technology expenses typically ranging from $50,000 to $250,000.

- Utilities Setup: Ensuring that the facility has reliable water, electricity, and drainage systems can add further to your investment, with costs potentially reaching around $20,000 to $50,000.

Tips for Reducing Construction Costs

- Consider leasing existing facilities that meet regulatory requirements to minimize renovation costs.

- Engage with local contractors who are familiar with oxygen production facility standards to optimize your budget.

- Explore grant opportunities or local economic development incentives that may subsidize construction or renovation costs.

Taking into account the operational costs of an oxygen plant, including utilities, labor, and maintenance, can further affect your financial planning for oxygen plant operations. It’s also important to consult with professionals who have experience in setting up similar facilities to ensure that you are considering all necessary factors in your budget planning.

For those looking to secure funding options for their oxygen plant, detailed financial models can be invaluable. Comprehensive plans, such as those available at Financial Model Templates, can help you analyze startup costs effectively and attract potential investors.

Licensing and Permits

When starting an oxygen plant business, understanding the licensing requirements for oxygen plants is crucial. These regulations vary by country and region and can significantly impact the oxygen plant startup costs and overall operation. Obtaining the necessary permits not only ensures compliance with legal standards but also builds trust with potential customers and stakeholders.

Here are some common licenses and permits you may need to secure:

- Business License: A general requirement to legally operate any business.

- Environmental Permits: These are essential for any facility that may impact air quality, water resources, or surrounding ecosystems.

- Health and Safety Permits: Required to ensure the safety of your plant operations and adherence to regulations set by health authorities.

- Production Licenses: Specific to the production of medical-grade oxygen, which often necessitates additional certifications.

- Fire Safety Permits: Relevant for any facility storing or using potentially flammable materials.

The cost to start an oxygen plant includes various business expenses, and licensing can be a significant portion. For instance, environmental permits can range from $5,000 to $50,000, depending on regulations in your region. Similarly, health and safety permits can add another $2,000 to $15,000 to your budget.

Tips for Securing Licensing and Permits

- Research local regulations thoroughly to avoid any compliance issues.

- Consult with legal experts specializing in industrial operations to streamline the application process.

- Budget for the time and financial investment needed to ensure all permits are in order before commencing operations.

In addition to these initial costs, consider that operational costs of oxygen plants may also involve ongoing licensing fees, which should be factored into your financial planning for the oxygen plant. Regular renewals and compliance checks can add to the yearly budget, so being prepared is essential for effective financial planning strategies for oxygen production.

| Type of License/Permit | Estimated Cost USD | Frequency |

|---|---|---|

| Business License | $300 - $1,000 | Annually |

| Environmental Permit | $5,000 - $50,000 | Varies |

| Health and Safety Permit | $2,000 - $15,000 | Annually |

| Production License | $10,000 - $100,000 | Every few years |

In summary, the licensing landscape for an oxygen production business demands careful attention. Aside from regulatory compliance, these steps can influence your business's sustainability and growth potential, as they directly correlate with your ability to operate legally and efficiently in a competitive market.

For detailed financial projections and to better understand oxygen plant funding options, you may consider utilizing structured financial models. This resource can assist in assessing the total investment in oxygen plant operations, including licensing and permitting factors, ensuring you have a comprehensive view of your startup costs.

For more insights, visit Oxygen Plant Financial Model.

Initial Raw Materials and Supplies

When considering the cost to start an oxygen plant, one of the primary components that operators must account for is the expense associated with initial raw materials and supplies. These costs can significantly impact the overall oxygen plant startup costs as they directly influence the efficiency and quality of production. The quality of raw materials is essential for ensuring that the oxygen produced meets industry standards, especially in sectors such as healthcare, which has stringent requirements.

The initial raw materials needed for production can vary based on the technology employed, with most oxygen plants relying on the following key components:

- Crystallized oxygen and nitrogen gas

- Purification chemicals

- Storage tanks and cylinders

- Compressors and other associated gas handling equipment

To give a clearer picture of the expenses involved, here’s a breakdown of typical costs associated with **initial raw materials and supplies**:

| Material | Estimated Cost (USD) | Usage Purpose |

|---|---|---|

| Crystallized Oxygen | $3,000 - $5,000 | Raw material for oxygen production |

| Purification Chemicals | $1,500 - $3,000 | To ensure purity of oxygen |

| Storage Components | $2,000 - $4,000 | Safety storage of produced gases |

| Gas Handling Equipment | $5,000 - $10,000 | Necessary for gas compression and distribution |

By paying close attention to raw material costs for oxygen production, business owners can effectively manage their oxygen production business costs. Furthermore, there are options to explore for cost savings:

Tips to Reduce Raw Material Costs

- Consider bulk purchasing agreements with suppliers to lower per-unit costs.

- Research alternative suppliers who offer competitive pricing for high-quality materials.

- Invest in technology that improves material efficiency and reduces waste.

Ultimately, the investment in an oxygen plant will be influenced heavily by choices made regarding initial raw materials and supplies. Ensuring that these materials are both quality and cost-effective is vital for the long-term operational success of your oxygen plant business. The proper financial planning for oxygen plant operations should also incorporate these costs to create a comprehensive budget.

For more detailed insights and a robust financial model tailored to the oxygen plant industry, visit this link.

Technology and Software Development

In the world of oxygen production, technology and software development stand as crucial components of startup costs. For an oxygen plant startup like Oxygen Innovations, investments in advanced technological systems are essential to ensure efficiency, safety, and compliance with regulatory standards. The costs associated with technology development can vary significantly, typically ranging from $100,000 to $500,000, depending on the scale and complexity of the operations.

When starting an oxygen plant business, it is vital to consider different aspects of technology and software:

- Automation Systems: Investing in automation technology enhances productivity and ensures consistent quality in oxygen production. This may involve costs from $50,000 to $200,000 for necessary equipment and software.

- Monitoring and Control Software: These systems help in tracking operational parameters, ensuring safety, and maintaining compliance with industry standards. Implementation may require $20,000 to $100,000.

- Data Analytics Technologies: Having robust data analytics software can help optimize production processes and manage inventory more effectively. Initial costs can be around $10,000 to $50,000.

- Maintenance and Support Costs: Regular updates and technical support are necessary to keep systems running smoothly, which can accumulate to approximately $5,000 to $20,000 annually.

To effectively manage these costs, financial planning for an oxygen plant is crucial. A detailed budget should outline technology expenses, ensuring alignment with overall investment goals.

Tips for Cost-Effective Technology Management

- Prioritize essential technology that directly impacts production efficiency to avoid overspending.

- Explore partnerships with technology providers to reduce initial costs through leasing or financing options.

- Conduct a thorough market analysis to identify the most suitable technologies that meet both regulatory and production needs.

In terms of specific technology costs, a breakdown of typical expenses may look like this:

| Technology/Software | Estimated Cost | Description |

|---|---|---|

| Automation Systems | $50,000 - $200,000 | Enhances productivity and quality control. |

| Monitoring Software | $20,000 - $100,000 | Ensures compliance and safety. |

| Data Analytics | $10,000 - $50,000 | Optimizes production processes. |

| Maintenance Support | $5,000 - $20,000/year | Essential for ongoing operations. |

Investing in technology for an oxygen production business not only facilitates efficiency but also enhances safety compliance and operational reliability. As the oxygen market continues to grow, leveraging the right technology can set businesses apart. For more detailed financial planning strategies, the Oxygen Plant Financial Model can provide a valuable resource.

Safety and Compliance Upgrades

When starting an oxygen plant business, one of the most critical components of your startup costs will be safety and compliance upgrades. The oxygen production industry is heavily regulated due to the potential hazards associated with handling pure oxygen and other gases. Ensuring that your facility adheres to all necessary regulations not only prevents costly fines but also ensures the safety of your employees and the communities you serve.

According to industry standards, budget anywhere from 10% to 20% of your total startup costs for safety and compliance upgrades. For a typical oxygen plant, where the total startup costs can range from $500,000 to $2 million, this translates to an investment of approximately $50,000 to $400,000.

The key areas of focus for safety and compliance include:

- Facility Design and Layout: The design must minimize risks, including proper ventilation, access controls, and safe gas storage areas.

- Safety Equipment: Investing in high-quality safety gear, such as personal protective equipment (PPE), fire suppression systems, and gas detection devices.

- Training Programs: Ensuring all staff are trained in safety protocols and emergency procedures. This may involve additional costs for professional training services.

- Regular Inspections: Budget for periodic inspections and audits by safety compliance experts to ensure ongoing adherence to regulations.

- Insurance Requirements: Higher insurance premiums may apply due to the nature of the business; these costs should be factored into your financial planning.

| Cost Item | Estimated Cost Range | Notes |

|---|---|---|

| Facility Design and Layout | $20,000 - $100,000 | Includes engineering and design services |

| Safety Equipment | $15,000 - $80,000 | Costs for PPE and safety installations |

| Training Programs | $5,000 - $30,000 | Ongoing training for new and existing employees |

Investing in the right safety and compliance upgrades from the start will not only maintain operational efficiency but also provide your oxygen plant with a solid reputation. Failing to adhere to safety standards can lead to severe repercussions, potentially jeopardizing your investment in the oxygen plant.

Tips for Reducing Safety and Compliance Costs

- Explore group training programs with other oxygen production businesses to lower training expenses.

- Consider funding opportunities specifically for safety upgrades that some government programs offer.

- Negotiate contracts with suppliers for safety equipment to obtain bulk discounts.

Ultimately, for anyone venturing into the oxygen production business, understanding the operational costs of an oxygen plant—especially concerning safety and compliance—is essential. Alongside other startup costs, such as equipment purchase and facility construction, strategically planning for these expenses will ensure smoother operations. For detailed financial projections and templates to guide your planning, consider visiting Oxygen Plant Financial Model.

Marketing and Branding Costs

When starting an oxygen plant business like Oxygen Innovations, one of the crucial investments that should not be overlooked is marketing and branding. In a competitive market where the demand for high-quality oxygen is growing, establishing a strong brand identity and effective marketing strategy is essential for attracting clients and building a loyal customer base.

The costs associated with marketing and branding can vary significantly based on the methods chosen and the scale of the marketing efforts. Here are some key components of these expenses:

- Brand Development: Creating a unique brand identity, including logo design, color schemes, and overall brand messaging, can range from $5,000 to $15,000.

- Website Development: An informative and user-friendly website is crucial for any business. Developing a professional website can cost between $3,000 and $10,000, including hosting and maintenance.

- Digital Marketing: This includes social media advertising, search engine optimization (SEO), and pay-per-click (PPC) campaigns. Expect to spend around $1,000 to $5,000 per month depending on your strategy.

- Print Marketing Materials: Brochures, business cards, and other collateral can cost between $500 and $2,000 during the initial setup phase.

- Industry Events and Trade Shows: Attendance and participation in relevant trade shows can range from $1,500 to $10,000 per event, depending on the prominence of the trade show.

Considering these aspects, it is important to allocate a substantial portion of your budget to marketing and branding as these costs will directly impact your visibility and market penetration in the oxygen production business.

Tips to Optimize Marketing Costs

- Prioritize digital marketing strategies over traditional methods to reach a larger audience at a lower cost.

- Leverage social media platforms to increase brand awareness and directly engage with potential customers.

- Use analytics tools to track the effectiveness of your marketing campaigns and adjust accordingly for better ROI.

To give you a clearer picture, here is a basic cost breakdown of marketing expenses for an oxygen plant startup:

| Expense Category | Estimated Cost | Percentage of Total Marketing Budget |

|---|---|---|

| Brand Development | $10,000 | 20% |

| Website Development | $5,000 | 10% |

| Digital Marketing | $12,000 (annual) | 30% |

| Print Marketing Materials | $1,500 | 5% |

| Industry Events | $5,000 | 15% |

| Miscellaneous | $3,500 | 5% |

| Total | $37,000 | 100% |

Establishing a robust marketing strategy is invaluable for any business, especially for an oxygen production business aiming to carve out a niche in a growing market. Allocating a well-thought-out budget for marketing and branding could ultimately determine the success of your venture.

For a more comprehensive financial plan tailored to your needs, consider utilizing tools designed specifically for oxygen plant businesses. You can find resources such as financial models that assist in investment planning [here](https://financialmodeltemplates.com/products/oxygen-plant-financial-model).

Research and Development Expenses

Research and development (R&D) expenses are a crucial component of the startup costs associated with an oxygen plant business like Oxygen Innovations. These costs play a pivotal role in enhancing production efficiency, ensuring compliance with industry standards, and fostering innovation in oxygen production technology. Engaging in thorough R&D not only increases the potential for high-quality oxygen supply but also addresses the growing demand across various sectors.

The investment in R&D for an oxygen production business can vary significantly based on the scale and technological aspirations of the facility. According to industry benchmarks, R&D expenses can account for approximately 15% to 20% of the total startup costs. This percentage can translate into a substantial amount depending on the overall budget allocated for launching the business.

Some of the primary areas where R&D expenses may arise include:

- Development of innovative oxygen production methods that enhance efficiency.

- Testing and optimizing production equipment to maximize output while minimizing resource consumption.

- Conducting market research to align product offerings with customer needs and industry trends.

- Ensuring compliance with safety and environmental regulations, which often requires specialized research.

For an effective financial planning strategy for an oxygen plant, it is essential to consider the following typical R&D expenses:

| R&D Expense Category | Estimated Cost Range | Percentage of Total R&D Budget |

|---|---|---|

| Innovative Technology Development | $50,000 - $200,000 | 30% - 50% |

| Market Research | $20,000 - $50,000 | 15% - 20% |

| Safety Compliance Research | $10,000 - $30,000 | 10% - 15% |

| Testing and Quality Assurance | $15,000 - $40,000 | 15% - 25% |

It’s important to note that while these expenses can seem daunting, they are indispensable for the long-term success of the oxygen plant. Investing in R&D not only leads to superior quality oxygen production but also fosters a culture of innovation within the organization.

Tips to Optimize R&D Costs

- Utilize pilot projects to test new technologies on a smaller scale before full implementation.

- Collaborate with research institutions or universities to access grants or shared resources.

- Focus on specific areas where innovations can have the most significant impact on efficiency and cost savings.

In conclusion, understanding and planning for R&D expenses are essential components when considering the cost to start an oxygen plant. By conducting a well-researched R&D strategy, Oxygen Innovations can align itself with industry standards and capitalize on the latest technological advancements, ultimately positioning itself as a leader in the oxygen supply industry. For further insights on how to manage these expenses effectively, consider exploring financial models tailored for oxygen production ventures, such as those found at this link.

Insurance and Bonding Costs

When starting an oxygen plant business, it's essential to factor in the insurance and bonding costs that are required to protect your investment and ensure compliance with regulations. These costs can significantly impact your overall oxygen plant startup costs, and understanding them will help in your financial planning for oxygen plant.

Insurance is critical for providing coverage against potential liabilities, equipment failures, and other unforeseen incidents. The types of insurance you may need include:

- General Liability Insurance

- Property Insurance

- Workers' Compensation Insurance

- Product Liability Insurance

- Professional Liability Insurance

On average, the cost of obtaining these insurance policies can range from $5,000 to $20,000 annually, depending on the scale of operations and the type of coverage selected. Additionally, bonding costs—typically required for compliance with regulatory standards—can add another 1% to 5% of the total project costs to your budget.

| Type of Insurance | Estimated Annual Cost | Coverage Scope |

|---|---|---|

| General Liability Insurance | $1,000 - $7,000 | Covers third-party injuries and property damage |

| Workers' Compensation Insurance | $2,000 - $10,000 | Provides wage replacement and medical benefits |

| Product Liability Insurance | $500 - $5,000 | Protects against claims related to product defects |

Securing the right insurance policies and bonding is not only about compliance but also about peace of mind. Here are some tips to manage your insurance costs effectively:

Tips for Managing Insurance and Bonding Costs

- Seek multiple quotes from different insurance providers to compare rates.

- Consider bundling policies to receive discounts.

- Invest in safety training and compliance measures to reduce risk and potentially lower premiums.

Additionally, the operational costs of an oxygen plant will also require a careful analysis to understand how insurance fits into your overall oxygen production business costs. Make sure that your financial plan includes these essential expenses to avoid any surprises that could jeopardize your startup.

Ultimately, having a robust insurance strategy is just as important as your capital investment in oxygen plant equipment and infrastructure. Assessing these needs early on will ensure that you are adequately covered while establishing your position in the burgeoning market of oxygen supply.