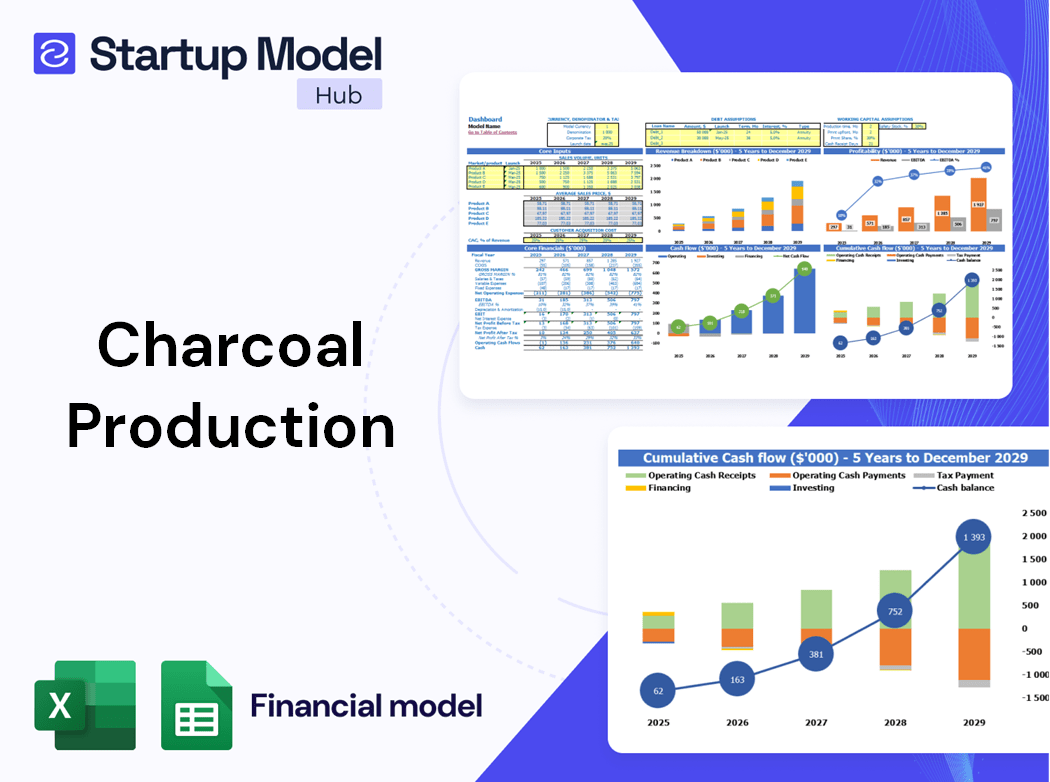

- 5-Year Financial Projection

- 40+ Charts & Metrics

- DCF & Multiple Valuation

- Free Email Support

Related Blogs

Are you ready to elevate your charcoal production business? Understanding the core 7 KPI metrics is essential for tracking performance and driving profitability. From calculating your Production Efficiency Rate to monitoring Customer Satisfaction Scores, these metrics provide a comprehensive framework to keep your operations aligned with strategic goals. Discover how to effectively harness these insights by exploring our detailed guide, and give your business the competitive edge it deserves. For a deep dive into financial planning, check out this business plan.

Why Is Tracking KPI Metrics Important For Charcoal Production Business?

In the competitive landscape of charcoal production, particularly for an innovative business like EcoCharcoals Inc., tracking KPI metrics for charcoal production business is crucial for sustainable growth and success. By monitoring financial KPIs for charcoal production and operational KPIs in charcoal production, businesses can make informed decisions that enhance efficiency and profitability.

Tracking these key performance indicators (KPIs) helps in identifying strengths and weaknesses, allowing businesses to pivot strategies effectively. For instance, a research report indicates that companies that actively track KPIs can improve their operational efficiency by up to 20% and increase profit margins by 15% on average. This data underscores the importance of using charcoal production KPIs to enhance productivity and operational performance.

Furthermore, these metrics provide valuable insights into market trends, customer preferences, and supply chain performance. Here are a few reasons why tracking KPIs is essential for charcoal production businesses:

- Performance Measurement: Regular tracking enables businesses to assess production efficiency and determine production efficiency in charcoal business.

- Cost Management: Understanding cost analysis in charcoal production helps in reducing waste and optimizing budget allocations.

- Quality Assurance: Collecting data on customer feedback in charcoal production can lead to improved product quality and customer loyalty.

- Strategic Alignment: Aligning KPI metrics with strategic objectives ensures that the entire organization works towards common goals.

Tips for Effective KPI Tracking

- Regularly review and update KPIs to reflect changing market conditions and operational challenges.

- Utilize automation tools for tracking charcoal production performance to save time and reduce errors.

- Involve all team members in KPI discussions to foster accountability and engagement.

Incorporating KPI tracking in decision-making processes can significantly boost the charcoal market competitiveness indicators, ensuring EcoCharcoals Inc. remains a leader in sustainable production. By focusing on the right metrics, businesses can enhance their operational strategies, ultimately driving growth and profitability.

What Are The Key Financial KPIs For Charcoal Production Business?

Financial KPIs play a crucial role in tracking the financial health of a charcoal production business like EcoCharcoals Inc. By understanding these key performance indicators, businesses can make informed decisions that align with their strategic goals. The following financial KPIs are essential in the charcoal industry:

- Revenue Growth Rate: This metric measures the increase in sales over a specific period. A strong revenue growth rate (ideally over 10% annually) indicates that the business is effectively reaching its market.

- Cost Per Unit Produced: Understanding your production costs is vital. This metric is calculated by dividing total costs by the number of units produced. Keeping this cost below $1 per kg of charcoal can enhance profitability.

- Gross Profit Margin: This KPI is critical as it provides insights into the financial viability of the production process. Calculated as (Revenue - Cost of Goods Sold) / Revenue, a healthy gross profit margin should be above 30% for sustainable operations.

- Return on Investment (ROI): This measures the profitability of investments made in production technology and processes. A desirable ROI in the charcoal business typically exceeds 20%.

- Operating Cash Flow: This KPI reflects the cash generated from operations, crucial for maintaining liquidity. A positive cash flow allows businesses to invest in growth opportunities and manage expenses effectively.

- Customer Acquisition Cost (CAC): Understanding how much it costs to acquire a new customer is essential for budgeting marketing expenses. Maintaining a CAC below 15% of the lifetime value (LTV) of the customer can ensure profitability.

- Break-even Point: This is the level of sales at which total revenues equal total costs. Knowing the break-even point helps in setting sales targets and pricing strategies.

Tips for Effective Financial KPI Tracking

- Regularly review and adjust KPI targets based on market trends and production efficiency to ensure alignment with strategic objectives.

- Utilize financial modeling techniques to project future performance and compare against historical data.

- Implement automated tracking systems for real-time data analysis, enhancing decision-making capabilities.

For further insights on the importance of tracking KPI metrics for charcoal production business, consider exploring this article on profitability in charcoal production.

Which Operational KPIs Are Critical For Charcoal Production Business?

In the charcoal production industry, operational KPIs are essential for tracking performance and ensuring efficiency. For a business like EcoCharcoals Inc., which aims to produce sustainable charcoal from agricultural waste, focusing on the right operational KPIs can significantly enhance productivity and profitability. Here are some of the most crucial operational KPIs in charcoal production:

1. Production Efficiency Rate

This metric assesses the output of charcoal production relative to the amount of raw materials utilized. A production efficiency rate of 80% or higher is often considered ideal in the industry.

2. Cost Per Unit Produced

Monitoring the cost associated with producing a single unit of charcoal allows businesses to identify areas for cost reduction. For example, if the average cost per unit is $10, analyzing inputs can help lower this to $8, enhancing profit margins.

3. Waste Reduction Percentage

Given the emphasis on sustainability, measuring waste reduction is critical. A target of reducing waste by 15-20% can reflect an effective operational strategy, especially when utilizing agricultural by-products.

4. Supplier Reliability Index

This KPI measures the reliability of suppliers in delivering necessary materials to ensure consistent production. A reliability index of 90% or above is ideal, helping maintain production schedules without delays.

5. Employee Productivity Rate

Assessing employee productivity is vital for understanding labor efficiency. A productivity rate of 75% or higher indicates that workers are effectively contributing to the production process.

Tips for Calculating Operational KPIs

- Regularly update your calculations based on current production trends to ensure accuracy.

- Implement a more efficient waste management system to lower costs and improve waste reduction percentages.

- Conduct monthly reviews of supplier performance to maintain high reliability indices.

Tracking these operational KPIs not only optimizes the production process but also reinforces EcoCharcoals Inc.'s commitment to sustainability. Utilizing these metrics will help maintain a competitive edge in the evolving charcoal market, where efficiency and responsibility are paramount.

How Often Should Charcoal Production Business Review And Update Its KPIs?

Regularly reviewing and updating KPI metrics for charcoal production business is essential for maintaining operational efficiency and achieving strategic objectives. A suggested frequency is to conduct a thorough review on a quarterly basis, with monthly check-ins to monitor crucial charcoal production KPIs such as production efficiency and cost management.

In the charcoal production sector, where market dynamics can shift rapidly due to changes in consumer preferences or regulatory requirements, timely adjustments can significantly impact profitability and sustainability. For instance, studies indicate that businesses that actively manage and update their key performance indicators for charcoal see a performance improvement of up to 20%.

When assessing the importance of KPIs in the charcoal business, consider the following:

- **Quarterly Reviews:** Analyze financial KPIs for charcoal production, such as revenue growth and return on investment, to ensure alignment with growth targets.

- **Monthly Check-Ins:** Evaluate operational KPIs in charcoal production, like production efficiency rate and waste reduction percentage, to promptly identify issues and implement corrective measures.

- **Annual Strategy Overhaul:** Dedicate a comprehensive annual review to assess the long-term KPIs and realign them with evolving business goals and market conditions.

Tips for Effective KPI Review

- Utilize performance dashboards for real-time tracking of charcoal production efficiency metrics.

- Engage employees in the review process to gain insights that can lead to improved measuring employee performance in charcoal production.

- Benchmark your KPIs against industry standards to gauge competitiveness within the charcoal market competitiveness indicators.

According to industry reports, companies that establish a regular KPI review frequency for charcoal businesses are more adaptive, often outperforming competitors by at least 15% in key metrics. This proactive approach ensures that business success metrics for charcoal are not only met but exceeded, particularly in the context of an eco-friendly initiative like EcoCharcoals Inc., which focuses on sustainable practices.

Furthermore, adapting KPIs in line with business strategies is crucial; organizations that align KPI alignment with business strategies experience a noticeable improvement in their operational outcomes. Consider establishing an annual planning session dedicated to revising KPIs based on the evolving landscape of the charcoal production industry.

What KPIs Help Charcoal Production Business Maintain Competitiveness?

In the competitive landscape of the charcoal production industry, particularly for sustainable brands like EcoCharcoals Inc., monitoring key performance indicators (KPIs) is essential for maintaining an edge. Understanding and utilizing the right KPI metrics for charcoal production business can significantly enhance operational efficiency, financial health, and customer satisfaction. Here are several critical KPIs that can help bolster competitiveness:

- Production Efficiency Rate: This metric evaluates the ratio of input resources to output products. A production efficiency rate of over 90% is considered excellent in the charcoal industry, ensuring minimal waste and maximum productivity.

- Cost Per Unit Produced: Calculating the cost per unit helps in assessing profitability. Industry benchmarks suggest that successful businesses aim to keep this figure below $60 per ton of charcoal produced.

- Customer Satisfaction Score: Leveraging customer feedback can directly impact repeat business. Aiming for a customer satisfaction score above 80% indicates a strong market position and loyalty.

- Return on Investment (ROI): Calculating ROI is critical for assessing overall profitability. A target ROI of at least 20% can indicate that the business is utilizing its capital effectively.

- Market Share Percentage: Tracking changes in market share can show how well the business is performing against competitors. A target increase in market share of 5-10% yearly indicates a strong brand presence.

To optimize these KPIs and remain competitive, businesses can employ various strategies, such as regular KPI reviews and adjustments to production processes. Understanding the importance of KPIs in charcoal business extends beyond mere numbers; it can foresee potential pitfalls and provide actionable insights.

Tips for Improving Competitive KPIs in Charcoal Production

- Implement continuous feedback loops with customers to enhance the customer satisfaction score.

- Conduct regular cost analysis in charcoal production to identify areas of expense reduction.

- Focus on waste management metrics for charcoal to lower the overall production cost.

- Engage employees through performance measurement to boost employee productivity rate.

By focusing on these KPIs, EcoCharcoals Inc. can not only improve its operational practices but also align its strategic objectives to ensure long-term growth and sustainability within the charcoal production market. For further insights, reviewing various industry benchmarks through resources like this article on charcoal profitability can provide invaluable information.

How Does Charcoal Production Business Align KPIs With Strategic Objectives?

Aligning KPI metrics for charcoal production business with strategic objectives is crucial for EcoCharcoals Inc. to maintain its leadership in the sustainable charcoal market. By correlating performance indicators with long-term goals, the business can ensure that every operational and financial decision contributes to broader ambitions such as sustainability, market expansion, and community support.

For instance, a key performance indicator (KPI) like the Production Efficiency Rate can directly serve the strategic objective of maximizing resource utilization and minimizing waste. This metric reflects the percentage of materials transformed into final products versus those discarded. Tracking this performance can help the company refine its manufacturing process, cutting down production costs by up to 15% and enhancing financial KPIs for charcoal production.

Moreover, aligning KPIs involves regularly assessing metrics that contribute to eco-friendly practices. The Waste Reduction Percentage is one such operational KPI in charcoal production that highlights the effectiveness of using agricultural waste. By maintaining this percentage above 25%, EcoCharcoals not only boosts its sustainability credentials but also appeals to a growing market of environmentally conscious consumers.

Another critical aspect of this alignment is the Customer Satisfaction Score. This KPI, derived from customer feedback, informs strategic decisions regarding product improvements and customer engagement strategies. Aiming for a score above 85% can enhance brand loyalty and position EcoCharcoals as a trusted leader in the green product market.

Tips for Effective KPI Alignment

- Regularly review and update charcoal production KPIs to reflect changes in business strategies and market conditions.

- Incorporate feedback loops where employee insights on operational efficiency can inform KPI adjustments.

- Benchmark against industry standards to gauge competitiveness and identify areas for improvement.

Furthermore, the Return on Investment (ROI) for marketing initiatives aimed at strategic markets enhances the alignment process. By evaluating marketing ROI, EcoCharcoals can ensure that resources are allocated effectively, achieving a return of at least 200% on promotional expenditures.

In conclusion, the careful alignment of key performance indicators for charcoal with strategic business objectives supports not only enhanced operational efficiency but also long-term sustainability and competitive positioning. Regular tracking and adjustment, alongside a robust understanding of market dynamics, are essential practices in this alignment process.

What KPIs Are Crucial For Success In Charcoal Production Business?

In the competitive landscape of the charcoal production industry, establishing robust KPI metrics for charcoal production business is essential for tracking performance and ensuring sustainable success. For innovative companies like EcoCharcoals Inc., which focuses on eco-friendly alternatives utilizing agricultural waste, these metrics play a critical role in driving operational efficiency and financial viability.

Production Efficiency Rate

The production efficiency rate is a vital operational KPI that measures the ratio of actual output to the potential output of the production process. To calculate this, use the formula:

Production Efficiency Rate = (Actual Output / Maximum Possible Output) x 100

Aiming for a production efficiency of over 85% can enhance overall profitability.

Cost Per Unit Produced

Understanding the cost per unit produced is crucial for maintaining profitability. This metric includes all variable and fixed costs associated with production. The formula is:

Cost Per Unit = Total Production Costs / Total Units Produced

Keeping this cost below $20 per ton can significantly impact profit margins.

Revenue Growth Rate

The revenue growth rate tracks how quickly a business is increasing its sales over time. This is calculated as:

Revenue Growth Rate = ((Current Period Revenue - Previous Period Revenue) / Previous Period Revenue) x 100

A healthy charcoal production business should aim for a revenue growth rate of at least 10% annually.

Customer Satisfaction Score

Maintaining a high customer satisfaction score is crucial, especially for businesses like EcoCharcoals that target environmentally conscious consumers. This score can be gauged through surveys and feedback, calculated as:

Customer Satisfaction Score = (Number of Satisfied Customers / Total Number of Surveyed Customers) x 100

Aiming for a score above 80% can enhance customer loyalty and repeat business.

Waste Reduction Percentage

The waste reduction percentage is a critical metric for assessing the sustainability of production methods. To calculate it:

Waste Reduction Percentage = (Waste Before - Waste After) / Waste Before x 100

Setting a target to reduce waste by more than 20% will not only help the environment but also reduce costs.

Return On Investment (ROI)

Calculating return on investment (ROI) will help evaluate the profitability of investments made in the charcoal production process. The formula is:

ROI = (Net Profit / Cost of Investment) x 100

Businesses should aim for an ROI of at least 15% to ensure that investments are fruitful.

Employee Productivity Rate

The employee productivity rate is crucial for operational efficiency. This can be calculated as:

Employee Productivity Rate = Total Output / Number of Employees

Aiming for a productivity rate over 5 tons per employee per month indicates effective workforce management.

Market Share Percentage

Understanding the market share percentage helps evaluate a business's standing in the charcoal market. It is calculated by:

Market Share = (Company's Sales / Total Market Sales) x 100

Setting a goal to capture at least 15% of the market share can help establish a strong presence.

Supplier Reliability Index

This metric measures the dependability of suppliers to ensure continuous production. Calculating it often involves assessing delivery times and the quality of materials. The formula could include:

Supplier Reliability Index = (Number of Deliveries on Time / Total Deliveries) x 100

Aiming for a supplier reliability index of over 90% can help maintain production schedules.

Tips for Implementing KPIs in Charcoal Production

- Regularly review and adjust your KPIs based on market changes to stay competitive.

- Utilize monitoring software to automate KPI tracking for timely insights.

- Involve employees in understanding their performance metrics to boost morale and productivity.

By diligently tracking these charcoal production KPIs, businesses like EcoCharcoals Inc. can ensure they remain competitive while adhering to their commitment to sustainability.

Production Efficiency Rate

In the charcoal production business, the Production Efficiency Rate serves as a pivotal KPI metric that reflects how effectively resources are utilized in the manufacturing process. For EcoCharcoals Inc., where sustainability is at the heart of our operations, monitoring production efficiency not only ensures optimal use of agricultural waste but also aligns with our commitment to eco-friendly practices.

The Production Efficiency Rate can be calculated using the formula:

| Formula Component | Explanation |

|---|---|

| Actual Output | Total units of charcoal produced during a specific period |

| Potential Output | The maximum possible output based on the raw materials and resources available |

| Production Efficiency Rate | (Actual Output / Potential Output) x 100% |

For instance, if EcoCharcoals Inc. produced 8,000 kilograms of charcoal from available agricultural waste that could potentially yield 10,000 kilograms, the Production Efficiency Rate would be:

(8,000 / 10,000) x 100% = 80%

This metric is crucial for several reasons:

- Cost Management: Higher efficiency rates often correlate with lower production costs. An efficient process minimizes waste, thereby reducing overhead costs associated with raw materials.

- Quality Control: Tracking efficiency helps identify bottlenecks in production that may affect the final product quality, ensuring consistency in delivering environmentally friendly charcoal.

- Resource Optimization: By understanding production efficiency, EcoCharcoals Inc. can better allocate resources, ensuring that every kilogram of agricultural waste is used effectively.

Benchmarking against industry standards, a typical production efficiency rate for charcoal businesses can range between 70% to 90%. Achieving and maintaining a rate at the higher end of this spectrum is critical for staying competitive in the charcoal market.

Tips for Improving Production Efficiency Rate

- Regularly train employees on best practices and production techniques to enhance skill levels.

- Implement lean manufacturing principles to streamline processes and eliminate waste.

- Invest in technology that enhances automation and reduces human error in production.

In summary, tracking the Production Efficiency Rate is integral to measuring the overall performance of EcoCharcoals Inc. It directly influences financial KPIs, such as Cost Per Unit Produced and Revenue Growth Rate, making it a cornerstone of our operational metrics. By focusing on this KPI, we can not only improve production processes but also reinforce our commitment to sustainability in the charcoal production industry.

For more detailed financial modeling tailored specifically for charcoal production businesses, visit this link.

Cost Per Unit Produced

In the charcoal production business, understanding the Cost Per Unit Produced is crucial for assessing overall efficiency and profitability. This KPI helps businesses like EcoCharcoals Inc. identify how much it costs to produce a single unit of charcoal, which is essential for pricing strategies and financial planning. The formula to calculate this metric is:

Cost Per Unit Produced = Total Production Costs / Total Units Produced

Total production costs encompass various expenses, including raw materials, labor, overhead, and other variable costs. For a business focusing on sustainable practices, like EcoCharcoals Inc., these costs must also consider the eco-friendly sourcing of agricultural waste.

| Expense Category | Monthly Cost (USD) | Percentage of Total Cost |

|---|---|---|

| Raw Materials | 2,000 | 40% |

| Labor | 1,500 | 30% |

| Overhead | 1,000 | 20% |

| Miscellaneous | 500 | 10% |

| Total | 5,000 | 100% |

Using the above example of total monthly production costs of $5,000, if EcoCharcoals Inc. produces 1,000 units of charcoal, the cost per unit produced would be:

Cost Per Unit Produced = $5,000 / 1,000 = $5.00

Tracking this KPI is vital for several reasons:

- It aids in pricing decisions, ensuring profitability while remaining competitive.

- Identifying cost-saving opportunities by analyzing each expense category.

- Assessing production efficiency, especially in a sustainable production model.

Tips for Reducing Cost Per Unit Produced

- Regularly review supplier contracts to negotiate better rates for raw materials.

- Invest in production technology to enhance efficiency and reduce waste.

- Implement lean production techniques to streamline processes.

In a competitive market, maintaining a low cost per unit produced is essential for the sustainability of a charcoal production business. This is particularly important for businesses like EcoCharcoals Inc., where the focus on eco-friendly practices can sometimes lead to higher operational costs. By consistently monitoring and optimizing this KPI, the company can ensure its position as a market leader.

Comparing the cost per unit produced to industry benchmarks can also provide insights into performance. The average cost per unit in the charcoal industry typically ranges from $4.00 to $7.00, depending on the production methods and resource availability.

Moreover, understanding the impact of operational KPIs on cost control can lead to better decision-making for resource allocation and investment. As EcoCharcoals Inc. focuses on sustainable practices, integrating KPI tracking into its strategic objectives will enable continuous improvement and adaptation.

For more advanced financial modeling and comprehensive KPI tracking tailored to the charcoal production business, check out this charcoal production financial model.

Revenue Growth Rate

The Revenue Growth Rate is a crucial financial KPI for any charcoal production business, especially for EcoCharcoals Inc., which seeks to lead in sustainable charcoal production. This metric evaluates the increase in revenue over a specific period, revealing how well the business is expanding its market reach and sales. To accurately calculate the revenue growth rate, use the following formula:

Revenue Growth Rate (%) = ((Current Period Revenue - Previous Period Revenue) / Previous Period Revenue) * 100

For instance, if EcoCharcoals generated $200,000 in sales this year compared to $150,000 last year, the calculation would be:

Revenue Growth Rate = (($200,000 - $150,000) / $150,000) * 100 = 33.33%

Tracking this metric allows EcoCharcoals to gauge its performance and make informed decisions regarding marketing strategies, pricing adjustments, and product diversification. A consistent growth rate is indicative of a healthy business trajectory and proves the enterprise's ability to attract customers.

Tips for Maximizing Revenue Growth Rate

- Analyze customer feedback to align products with market demands.

- Invest in effective marketing strategies to reach environmentally conscious consumers.

- Diversify product offerings, such as different charcoal types or packaging options.

Moreover, companies in the charcoal production sector typically see revenue growth rates ranging from 15% to 30% annually, depending on market conditions and operational efficiency. By benchmarking against industry standards, EcoCharcoals can set realistic targets for its growth strategy.

| Year | Revenue | Revenue Growth Rate (%) |

|---|---|---|

| 2021 | $150,000 | - |

| 2022 | $200,000 | 33.33% |

| 2023 | $250,000 | 25% |

As EcoCharcoals focuses on sustainable practices, it will likely benefit from increased consumer awareness about environmental issues, potentially driving revenues upwards. By setting clear revenue targets and closely monitoring performance, EcoCharcoals can ensure its long-term viability and growth amidst rising competition in the charcoal market.

Understanding the significance of this KPI not only aids in tracking charcoal production performance but also helps in aligning with strategic objectives. By focusing on revenue growth, EcoCharcoals can highlight its commitment to sustainability while also capitalizing on market opportunities.

In addition, as the market evolves, adjusting the approach to maximize revenues while maintaining eco-friendly practices will be pivotal. For more detailed financial modeling and planning tailored to the charcoal production business, consider exploring resources like the Charcoal Production Financial Model.

Customer Satisfaction Score

The Customer Satisfaction Score (CSS) is a critical KPI metric for charcoal production businesses like EcoCharcoals Inc., especially in an era where consumer preferences lean towards sustainable and eco-friendly products. It serves as a direct reflection of how well your products meet customer expectations and the experience they have with your brand.

To calculate the Customer Satisfaction Score, you can use a straightforward survey method where customers rate their satisfaction on a scale of 1 to 10. The formula for calculating CSS is:

CSS = (Total Score from All Responses / Number of Responses) x 100

This calculation yields a percentage that helps gauge overall customer satisfaction. For instance, if you receive a total score of 850 from 100 responses, your CSS would be 85%. This score not only informs you about customer sentiment but is also vital for tracking charcoal production performance over time.

Maintaining a solid Customer Satisfaction Score can lead to enhanced customer loyalty, repeat purchases, and positive word-of-mouth referrals, which are invaluable for the growth of a sustainable business. According to industry benchmarks, a satisfaction score above 80% is considered excellent and can significantly boost your market competitiveness.

Tips to Improve Customer Satisfaction Score

- Conduct regular customer feedback surveys to understand needs and desires.

- Implement a responsive customer service strategy to address issues promptly.

- Engage with customers on social media to build a community around your sustainable brand.

Incorporating customer feedback into your operational KPIs is essential for continuous improvement. For instance, if surveys reveal that customers desire more sustainable packaging, addressing this concern not only enhances customer satisfaction but aligns with the business's core values of sustainability.

Furthermore, tracking your CSS can identify trends over time. If you observe a decline, it is crucial to delve into the underlying reasons—be it product quality, delivery times, or customer service—and make necessary adjustments.

Real-life statistical data indicates that companies with high customer satisfaction scores outperform their competitors by up to 20% in revenue growth. Additionally, the cost of acquiring new customers is typically five times higher than retaining existing ones, making the CSS a pivotal metric in your charcoal production strategy.

| Score Range | Customer Satisfaction Level | Action Required |

|---|---|---|

| 0-60 | Poor | Urgent improvements needed |

| 61-80 | Average | Monitor and enhance |

| 81-100 | Excellent | Maintain and leverage |

In summary, the Customer Satisfaction Score is not just a number; it is a vital part of your strategic objectives for the charcoal production business. Understanding how to calculate and interpret your CSS can guide you toward improving your offerings and retaining a loyal customer base. By leveraging your CSS along with other key performance indicators for charcoal production, EcoCharcoals Inc. can position itself favorably in the sustainably-focused market.

Waste Reduction Percentage

In the charcoal production industry, a crucial KPI metric to track is the waste reduction percentage. This metric reflects how effectively a business utilizes raw materials and minimizes waste, which is particularly important for sustainable producers like EcoCharcoals Inc. By focusing on waste reduction, the business not only cuts costs but also enhances its reputation as an environmentally friendly company.

The waste reduction percentage is calculated using the following formula:

| Waste Reduction Percentage | Formula | Description |

|---|---|---|

| Waste Reduction Percentage | ( Total Waste Generated - Total Waste Recycled or Repurposed ) / Total Waste Generated * 100 | Measures the percentage of waste that has been effectively reduced or recycled. |

For example, if EcoCharcoals Inc. generates a total waste of 100 tons in a production cycle and successfully recycles or repurposes 60 tons, the waste reduction percentage would be:

(100 - 60) / 100 * 100 = 40%

This means that 40% of the waste produced has been reduced through effective strategies, highlighting the company's commitment to sustainability.

Tracking this KPI helps in evaluating operational efficiency and identifying areas for improvement. By maintaining a low waste percentage, EcoCharcoals can also lower production costs significantly, thus impacting the bottom line positively. Additionally, it aligns with consumer preferences for green products, enhancing market competitiveness in the charcoal industry.

Tips for Improving Waste Reduction Percentage

- Regularly audit waste management practices to identify inefficiencies.

- Invest in training employees on best practices for waste disposal and recycling.

- Implement technology that enhances material recovery processes.

EcoCharcoals Inc. must also analyze the relationship between waste reduction and other operational KPIs such as production efficiency and cost analysis. By doing so, they can optimize processes further and ensure that sustainability measures translate into financial benefits.

Reports indicate that companies reducing waste by just 1% can save an estimated $7,000 annually in material costs, which highlights the financial stakes involved in improving this KPI.

As the charcoal production sector evolves, monitoring the waste reduction percentage becomes essential not only for compliance with environmental regulations but also for achieving long-term business success. This KPI serves as a benchmark for the industry, assisting in strategy formulation and performance enhancement in an environmentally conscious market.

To enhance understanding and management of this KPI, explore tools and templates designed specifically for the charcoal production sector, such as the financial models available at this link.

Return On Investment

Return on Investment (ROI) is a crucial KPI metric for any charcoal production business, especially for EcoCharcoals Inc. as it strives to innovate within the industry. ROI measures the profitability of investments in the business and helps assess the effectiveness of capital allocation. Understanding how to calculate ROI allows for informed decision-making which is vital for sustaining growth and ensuring financial health.

The formula for calculating ROI is straightforward:

ROI = (Net Profit / Cost of Investment) x 100

In the context of charcoal production, the cost of investment can include expenses such as equipment purchases, raw materials like agricultural waste, labor costs, and operational overheads. Net profit is calculated by taking total revenue from sales and subtracting all costs associated with production.

| Investment Type | Cost ($) | Expected Revenue ($) | Net Profit ($) | ROI (%) |

|---|---|---|---|---|

| Equipment Purchase | 50,000 | 80,000 | 30,000 | 60% |

| Marketing Campaign | 10,000 | 25,000 | 15,000 | 150% |

| Raw Material Sourcing | 15,000 | 40,000 | 25,000 | 166.67% |

For EcoCharcoals Inc., a high ROI reflects not only strong financial health but also validates the sustainability of its business model. This is particularly relevant as the company aims to appeal to eco-conscious consumers and support local economies.

Continuous monitoring of ROI can reveal trends that inform investment strategies, such as whether to scale production or diversify product lines. Moreover, tracking ROI alongside other financial KPIs for charcoal production offers a holistic view of business performance.

Tips for Improving ROI in Charcoal Production

- Regularly review operational costs to identify areas for waste reduction and efficiency improvements.

- Invest in technology that enhances production efficiency and lowers long-term operational costs.

- Engage with customers for feedback to refine product offerings and increase sales potential.

Understanding the importance of KPIs in charcoal business extends beyond just numbers; it encompasses strategic alignment with the company’s mission of sustainability and community support. Regularly calculating and analyzing ROI, along with other key performance indicators, will enhance the overall operational effectiveness and market positioning of EcoCharcoals Inc..

For more detailed insights into the financial modeling of a charcoal production business, including how to calculate KPIs effectively, visit this financial model resource.

Employee Productivity Rate

In the charcoal production business, particularly for companies like EcoCharcoals Inc., the Employee Productivity Rate serves as a vital KPI that measures the efficiency of labor and the overall output from employees. This metric can significantly influence both operational efficiency and financial performance within the context of sustainable charcoal production.

The Employee Productivity Rate can be calculated using the following formula:

Employee Productivity Rate = Total Output / Total Hours Worked

For EcoCharcoals Inc., understanding this KPI can reveal insights into workforce efficiency, ensuring that production targets are met effectively while maintaining the eco-friendly ethos of the business.

Key Considerations for Evaluating Productivity

- Assess the average output per employee to identify high performers and areas needing improvement.

- Implement training programs to bolster skills and efficiency, ultimately enhancing overall productivity.

- Utilize technology and automation where possible to streamline operations, reducing manual tasks and increasing output.

Benchmarking employee productivity in the charcoal production industry reveals interesting statistics. Industry standards suggest that an average employee in charcoal production can yield approximately 1,200 to 1,500 kg of charcoal per week. EcoCharcoals Inc. aims to exceed this average through targeted employee engagement and eco-conscious production techniques.

Furthermore, employee productivity is intertwined with operational KPIs in charcoal production, such as production efficiency and cost per unit produced. Tracking these KPIs together provides a comprehensive view of how workforce performance impacts overall business success.

It's essential to establish regular review cycles for tracking this KPI. A recommended frequency is monthly, allowing for timely adjustments and strategies that can lead to increased productivity. This could involve comparing productivity rates against seasonal production demands and aligning workforce efforts accordingly.

| Employee Productivity Rate | Industry Average | EcoCharcoals Inc. Target |

|---|---|---|

| 1,000 kg/week | 1,200 - 1,500 kg/week | 1,800 kg/week |

The adoption of eco-friendly practices may also influence employee morale and productivity. Engaging employees in sustainability initiatives can enhance their commitment to their work, leading to a more productive workforce. This aligns perfectly with the strategic objectives of EcoCharcoals Inc., positioning it as a leader in the charcoal market.

Ultimately, the Employee Productivity Rate not only reflects labor efficiency but also acts as a competitive KPI for charcoal production. Companies that can measure and enhance this metric effectively position themselves for greater market share and profitability.

For further insights, EcoCharcoals Inc. can utilize specialized tools and models for financial planning, such as those found at charcoal production financial models, which can help in calculating detailed KPIs and enhancing overall business strategies.

Market Share Percentage

Market share percentage is a critical KPI metric for charcoal production businesses like EcoCharcoals Inc., as it directly reflects the company's competitive positioning and overall market strength. This metric indicates the portion of the market that your business controls in relation to total industry sales and is essential for understanding how your products stack up against competitors in the eco-friendly charcoal market.

To calculate the market share percentage, use the following formula:

Market Share Percentage = (Company's Sales / Total Market Sales) x 100

For example, if EcoCharcoals Inc. achieves sales of $500,000 in a market worth $5,000,000, the market share percentage would be:

Market Share Percentage = ($500,000 / $5,000,000) x 100 = 10%

This 10% market share signifies that EcoCharcoals Inc. holds a noteworthy position within the charcoal industry, especially for sustainable products, which is a growing segment of the market.

| Year | Company's Sales ($) | Total Market Sales ($) | Market Share % |

|---|---|---|---|

| 2021 | 250,000 | 2,500,000 | 10% |

| 2022 | 400,000 | 4,000,000 | 10% |

| 2023 | 500,000 | 5,000,000 | 10% |

Tracking market share percentage not only helps in assessing competitive performance but also guides strategic decisions related to pricing, marketing, and product development. A sustainable business like EcoCharcoals must continuously evaluate its market share to ensure alignment with ecological and economic goals.

Tips for Improving Market Share

- Enhance customer engagement through targeted marketing campaigns that highlight the sustainability aspect of your products.

- Expand distribution channels by partnering with eco-friendly retailers and online marketplaces.

- Invest in product innovations that meet consumer demand for sustainable options, setting your brand apart from competitors.

In the context of KPI metrics for charcoal production business, maintaining a robust market share percentage is crucial for long-term viability and growth. With the increasing consumer shift toward green products, leveraging this KPI will help guide EcoCharcoals Inc. toward becoming a market leader in the charcoal production industry.

Furthermore, comparing market share with the performance of competitors can reveal opportunities for improvement and inform strategic decisions about entering new markets. For instance, if competitors are capturing larger shares due to aggressive pricing strategies, EcoCharcoals could consider adjusting its pricing model or enhancing its value propositions. Now is the time to harness the importance of KPIs in the charcoal business by focusing on market share as a primary indicator of success.

Supplier Reliability Index

The Supplier Reliability Index (SRI) is a critical KPI metric for charcoal production businesses like EcoCharcoals Inc., which prides itself on sustainability and efficiency. The SRI evaluates the dependability of suppliers in providing quality materials on time, which is essential for maintaining production schedules and ensuring product quality. A high SRI indicates reliable suppliers who meet delivery timelines and quality standards, fostering operational efficiency and reducing costs.

To calculate the Supplier Reliability Index, the following formula can be used:

SRI = (Number of On-Time Deliveries / Total Deliveries) * 100%

For instance, if EcoCharcoals Inc. received 200 deliveries from suppliers over a quarter and 180 of them were on time, the calculation would reflect:

SRI = (180/200) * 100% = 90%

This 90% reliability illustrates a strong supplier performance, critical for the charcoal production process which relies heavily on consistent access to high-quality agricultural waste materials.

Tips for Improving Supplier Reliability Index

- Establish clear communication channels with suppliers to ensure timely updates and feedback.

- Perform regular assessments of supplier performance based on delivery times and quality metrics.

- Encourage suppliers to adopt best practices in their operations that align with your sustainability goals.

Monitoring the SRI provides invaluable insights into the operational KPIs in charcoal production and identifies potential risks associated with supplier performance. A reliable supply chain minimizes production disruptions and maximizes productivity, directly correlating with profitability. Industry benchmarks suggest that a reliable supplier performance is crucial, as approximately 70% of production efficiency is linked to the quality and timeliness of raw materials.

| Supplier Performance Metrics | Benchmarks (%) | Current EcoCharcoals Inc. SRI (%) |

|---|---|---|

| On-Time Deliveries | 95% | 90% |

| Quality Compliance | 98% | 96% |

| Cost Variance | 5% | 3% |

As EcoCharcoals Inc. aims to maintain its competitive edge in the charcoal market by focusing on environmentally friendly production, leveraging the Supplier Reliability Index not only enhances operational efficiency but also supports strategic objectives. This KPI aligns closely with the company’s mission to create a sustainable product that appeals to eco-conscious consumers.

Regular reviews of the SRI will further ensure that EcoCharcoals Inc. stays ahead in the charcoal production business, adapting to new supplier challenges and market changes. The importance of KPIs in the charcoal business cannot be overstated, as they serve as vital indicators of performance and strategic alignment.

For businesses looking to refine their understanding of financial KPIs for charcoal production or improve their charcoal production efficiency metrics, resources such as charcoal production financial models can provide essential insights and tools.