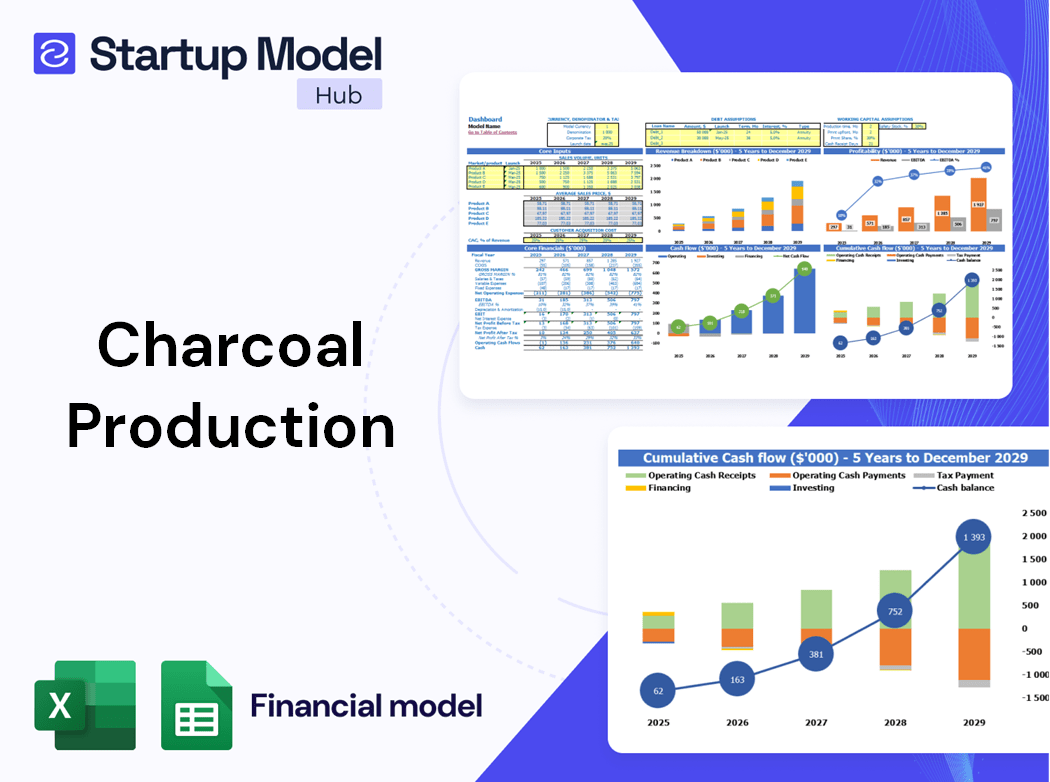

- 5-Year Financial Projection

- 40+ Charts & Metrics

- DCF & Multiple Valuation

- Free Email Support

Related Blogs

Are you considering diving into the lucrative world of charcoal production? Understanding the top nine startup costs is crucial for your success. From equipment purchases to branding expenses, knowing these financial essentials can make or break your business journey. To get a comprehensive overview and detailed financial plans, check out this business plan that will guide you through every step of the process.

How Much Does It Cost To Start A Charcoal Production Business?

Starting a charcoal production business, such as EcoCharcoals Inc., involves various startup costs for charcoal production that can significantly impact your initial investment. The costs can vary widely depending on the scale of your operation, the location, and the type of equipment you choose. On average, the total initial costs of starting a charcoal business can range from $25,000 to $100,000.

Here’s a breakdown of the top costs involved in launching a charcoal production business:

- Equipment Purchase: The cost of charcoal production equipment, including kilns, grinders, and packaging machines, can range from $10,000 to $50,000.

- Initial Raw Materials: Sourcing agricultural waste and necessary additives requires an investment of $2,000 to $10,000.

- Site Acquisition and Preparation: Depending on whether you lease or purchase land, costs can vary from $5,000 to $20,000.

- Permits and Licenses: Obtaining the necessary charcoal business permits can cost anywhere from $1,000 to $5,000.

- Branding and Marketing Expenses: A solid marketing strategy, including logo design and promotional materials, can set you back $1,000 to $5,000.

- Legal Fees: Registering your business and drafting contracts may incur $1,000 to $3,000 in charcoal business legal fees.

- Utility Setup Costs: Initial setup for electricity and water connections can range from $1,000 to $3,000.

- Insurance: Protecting your business with property and liability coverage will typically cost around $500 to $2,000.

- Initial Labor Costs: Hiring and training employees can add another $3,000 to $10,000 to your budget.

Understanding these charcoal manufacturing startup expenses is crucial for creating an effective charcoal startup budget. To ensure you are well-prepared, consider the following tips:

Ways to Reduce Startup Costs for Charcoal Business

- Consider purchasing used equipment or leasing to minimize charcoal production equipment costs.

- Utilize local agricultural waste to lower raw materials for charcoal production expenses.

- Negotiate with suppliers for better rates on initial materials and services.

With careful planning and a clear understanding of the cost analysis for charcoal business, you can effectively navigate the financial landscape of your startup. For more detailed insights, consider checking resources like this guide on charcoal production costs.

Is It Possible To Start A Charcoal Production Business With Minimal Investment?

Starting a charcoal production business can indeed be achieved with minimal investment, especially if you leverage existing resources and adopt cost-effective strategies. As highlighted by various industry studies, including insights from relevant charcoal production articles, the initial costs for setting up a charcoal production facility can range from $5,000 to $50,000, depending on the scale of operations and equipment used.

To successfully minimize expenses, consider the following strategies:

Cost-Saving Strategies for Charcoal Production

- Utilize locally sourced agricultural waste as raw materials, which can significantly reduce the cost to produce charcoal.

- Opt for used or refurbished charcoal production equipment to lower upfront investment costs.

- Consider starting on a smaller scale or in phases, allowing for gradual capital investment as the business grows.

- Engage in community partnerships for shared resources and knowledge, potentially decreasing initial labor and operational costs.

While initial investment in a charcoal production business can be daunting, there are creative ways to lessen the financial burden. For instance, negotiating flexible lease agreements for site preparation can mitigate upfront site acquisition costs. It is also important to keep in mind the ongoing expenses in charcoal production, such as utility costs and legal fees, which can be managed through efficient financial planning and budgeting.

According to recent data, labor costs for hiring and training employees can be controlled by utilizing part-time or seasonal workers during peak production times. Moreover, marketing costs can be minimized through free social media promotion and grassroots marketing strategies, helping to build brand awareness for EcoCharcoals Inc. without heavy spending.

In summary, with a strategic approach and a solid understanding of charcoal manufacturing startup expenses, it is absolutely feasible to launch a charcoal production business on a budget. By focusing on cost-effective methods and resourcefulness, aspiring entrepreneurs can pave their way to success in the eco-friendly charcoal industry.

Which Costs Can Be Reduced for a Charcoal Production Business?

Starting a charcoal production business, like EcoCharcoals Inc., comes with various expenses that can be daunting. However, understanding where to cut costs can significantly ease the initial financial burden. Here are key areas where savings can be made:

- Equipment Costs: Consider utilizing second-hand or refurbished charcoal production equipment to lower the charcoal production equipment costs. Research local suppliers who might offer equipment rental options instead of outright purchase.

- Raw Materials: Source agricultural waste locally to reduce costs associated with procurement and transportation. This not only minimizes initial investment charcoal production but also supports local farmers.

- Site Preparation: Look for existing facilities that can be adapted for production rather than starting with a brand-new site, which can significantly cut down site preparation for charcoal business costs. A preliminary site rental agreement may also be more affordable than purchasing land.

- Permits and Licenses: Streamlining the application process for charcoal business permits can save both time and money. Engaging a local consultant proficient in these matters might actually reduce overall legal fees in the long run.

- Marketing Expenses: Utilize social media platforms and free online marketing tools to establish your brand presence instead of investing heavily in traditional advertising. A strong digital marketing strategy can keep marketing costs charcoal production low while effectively reaching your target audience.

- Insurance: Shop around for the best rates on insurance for charcoal production and consider bundling policies to get discounts. Often, small businesses can negotiate better premiums based on their specific needs.

- Utility Costs: Implement energy-efficient practices to lower utility costs for charcoal manufacturing. Simple adjustments, like using energy-efficient kilns, can lead to substantial savings in the long run.

- Labor Costs: Start with a smaller team and cross-train employees to handle multiple roles. By carefully planning initial hiring, you can manage hiring employees for charcoal business expenses effectively.

Cost-Saving Tips for Charcoal Production Startups

- Collaborate with local agricultural businesses for raw materials, which can also help in establishing a good community network.

- Invest in training your staff to enhance efficiency, leading to reduced labor costs and improved productivity.

- Seek out government grants or subsidies tailored for sustainable businesses, which may alleviate some of your initial costs.

With these strategies, entrepreneurs can effectively reduce their startup costs for charcoal production while maintaining a solid operational foundation. It’s essential to keep a close eye on your charcoal startup budget and continuously seek innovative ways to minimize expenses.

Examples Of Startup Budgets For Charcoal Production Businesses

When considering how to start a charcoal production business, it’s crucial to plan your startup budget carefully. The costs can vary significantly based on location, scale, and the technologies employed, but here are examples of typical startup costs for a charcoal manufacturing startup.

- Equipment Purchase: The cost of kilns, grinders, and packaging machines can range from $10,000 to $50,000 depending on the technology chosen and production capacity.

- Initial Raw Materials: Sourcing agricultural waste and necessary additives may require an initial investment of about $2,000 to $10,000.

- Site Acquisition and Preparation: Renting or purchasing land suitable for charcoal production can cost anywhere from $5,000 to $20,000, depending on location and local real estate markets.

- Permits and Licenses: Acquiring the required environmental and operational permits could represent an expense of approximately $1,000 to $5,000.

- Branding and Marketing Expenses: Developing a brand identity, including creating a logo and website, along with promotions, may require $500 to $3,000.

- Legal Fees: Business registration and contract drafting can incur costs ranging from $1,000 to $4,000.

- Utility Setup Costs: The initial utility connection for electricity and water can add another $1,500 to $5,000.

- Insurance: Obtaining property and liability coverage will likely cost around $500 to $2,000 annually.

- Initial Labor Costs: If hiring employees for the charcoal business, expect to budget $3,000 to $10,000 for initial wages and training.

Overall, the total initial investment for a charcoal production business could range between $25,000 and $100,000 depending on various factors. This estimate aligns with findings in industry reports and can serve as a guiding framework for aspiring entrepreneurs.

Tips for Budgeting

- Always overestimate costs in your initial budget to prepare for unexpected expenses.

- Consider exploring cheaper alternatives for equipment and materials to reduce startup costs for charcoal production.

- Utilize local resources and partnerships to minimize marketing costs and enhance community engagement.

For a detailed breakdown and further financial analysis, you can refer to the article on charcoal production costs. Understanding these initial expenses can help set a realistic financial plan that aligns with your business goals.

How to Secure Enough Funding to Start a Charcoal Production Business?

Securing adequate funding is a crucial step for launching a charcoal production business, especially when considering the startup costs for charcoal production which can range from **$50,000** to **$200,000** depending on the scale and technology used. Understanding the specific expenses in charcoal production can help you articulate your financial needs clearly to potential investors or lenders.

First, create a detailed charcoal startup budget that outlines all projected costs, including:

- Charcoal production equipment costs: Kilns, grinders, and packaging machines can range from **$10,000** to **$100,000**.

- Raw materials for charcoal production: Initial supplies, primarily agricultural waste, can cost around **$5,000**.

- Site preparation for charcoal business: Land lease or purchase could require an investment between **$15,000** and **$50,000**.

- Charcoal business permits: Allocating around **$1,000 - $2,500** for necessary permits and licenses is critical.

- Marketing costs charcoal production: Branding and promotional activities could take around **$2,000** to **$5,000**.

- Charcoal business legal fees: Setting aside **$1,000 - $3,000** for registration and contracts.

- Utility costs for charcoal manufacturing: Initial setup for electricity and water connection may average **$3,000**.

- Insurance for charcoal production: Annual coverage can range from **$1,500** to **$5,000**.

- Hiring employees for charcoal business: Initial labor costs should be budgeted at approximately **$10,000**.

Once you have compiled your startup budget, explore various funding options:

- Personal Savings: Using personal funds is the most straightforward approach, but may limit your financial flexibility.

- Bank Loans: Traditional financing could work if you have a solid business plan. Be prepared to present your cost analysis for charcoal business.

- Investors: Attract investors by highlighting how your business, EcoCharcoals Inc., aligns with eco-friendly and sustainable practices appealing to a growing market.

- Government Grants and Subsidies: Research local and federal initiatives supporting sustainable businesses, which may provide non-repayable funding.

- Crowdfunding: Platforms like Kickstarter or Indiegogo can help you raise funds by engaging future customers interested in sustainable products.

Tips for Securing Funding

- Prepare an impressive business plan that includes financial projections, market analysis, and how your brand addresses sustainability.

- Network within industry circles to find investors and mentors who share your vision for eco-friendly production.

- Consider creating a prototype of your product to demonstrate its viability to potential backers.

By leveraging these funding strategies, you can effectively cover the initial investment in charcoal production and set your business on a path toward success. Effective financial planning for your charcoal production startup will also involve continuous monitoring of expenses and revenues to ensure your operation remains sustainable and profitable. For further insights, check out guidelines available at this resource.

How to Use the Financial Plan for Your Charcoal Production Business?

A well-structured financial plan is vital for the success of your charcoal production business. It serves as a roadmap, helping you navigate the significant startup costs associated with the venture. The costs can range dramatically depending on various factors, including equipment acquisition, raw materials, and site preparation. For a comprehensive understanding, let’s break down how to effectively utilize this financial plan.

Firstly, it’s essential to outline your initial investment in the charcoal production sector. The average startup costs for charcoal production can fall between $30,000 to $200,000, depending on the scale of your operation and equipment choices. Key components to consider include:

- Equipment purchase: This includes kilns, grinders, and packaging machines—typically, these can range from $10,000 to $50,000.

- Initial raw materials: Sourcing agricultural waste can cost approximately $5,000 to $20,000, depending on local availability.

- Site preparation: Land lease or purchase for your production facility could vary from $5,000 to $40,000.

- Permits and licenses: Securing the necessary certifications could incur costs from $1,000 to $5,000.

- Marketing expenses: Effective branding is crucial; budgeting around $1,000 to $10,000 for initial promotional efforts is common.

Incorporating cost analysis into your financial plan can help identify which areas are most likely to fluctuate. For instance, equipment prices may vary based on manufacturers or geographic location. This knowledge allows you to develop a more accurate charcoal startup budget.

Tips for Effective Financial Planning

- Regularly update your financial projections based on market trends and operational costs.

- Utilize financial modeling templates to simulate various scenarios and understand your profit margins.

Moreover, it’s crucial to plan for ongoing expenses in charcoal production, including utilities, insurance, and legal fees. Utility costs for charcoal manufacturing can add up, so budgeting $500 to $2,000 monthly for electricity and water is advisable. Insurance for your business should also be factored into your annual costs, typically ranging from $1,000 to $5,000 depending on coverage levels.

Lastly, securing financing is an integral component of using your financial plan effectively. Investors will want to see a detailed breakdown of your charcoal business financing and proof that you have considered potential challenges and expenses. A well-presented financial plan not only builds credibility but also increases your chances of obtaining the necessary funds to launch and sustain your business.

For more in-depth insights, consider checking out articles on the profitability and KPIs of charcoal production to further refine your financial approach: Profitability, KPIs.

What Are The Expenses To Start A Charcoal Production Business?

Starting a charcoal production business involves various expenses that can significantly impact your startup costs for charcoal production. Understanding these costs is crucial for effective financial planning. Here are the primary areas to consider:

Equipment Purchase (kilns, grinders, packaging machines)

Investing in the right charcoal production equipment is essential. Equipment costs can range between $10,000 to $50,000 depending on the scale of your operation. Key equipment needed includes:

- Kilns for charcoal carbonization

- Grinders for raw material preparation

- Packaging machines for product distribution

Initial Raw Materials (agricultural waste, additives)

The cost of raw materials for charcoal production can vary. A typical startup might require an initial investment of around $2,000 to $10,000, depending on sourcing agricultural waste and any necessary additives.

Site Acquisition and Preparation (land lease or purchase)

The site preparation for charcoal business includes the cost of leasing or purchasing land which can range from $5,000 to $20,000 depending on location and size.

Permits and Licenses (environmental and operational)

Obtaining the right charcoal business permits is crucial and can cost anywhere from $500 to $5,000. This varies by location and regulatory requirements.

Branding and Marketing Expenses (logo, website, promotions)

Effective branding helps in capturing market share, with costs for marketing costs charcoal production potentially amounting to $1,000 to $10,000. This includes logo design, website creation, and promotional materials.

Legal Fees (business registration, contracts)

Legal expenses, including charcoal business legal fees for registration and other contracts, can range from $500 to $3,000.

Utility Setup Costs (electricity, water connection)

Setting up utilities is another expense to consider. Initial utility costs for charcoal manufacturing can run from $1,000 to $5,000 based on your location.

Insurance (property, liability coverage)

To protect your business, consider insurance costs, which can range from $500 to $2,000 annually for insurance for charcoal production.

Initial Labor Costs (hiring, training)

Hiring skilled workers is critical. Initial labor costs, including hiring and training, can average around $3,000 to $10,000.

Tips for Reducing Startup Costs

- Consider purchasing used equipment to lower charcoal production equipment costs.

- Negotiate with suppliers for raw materials to reduce initial investment charcoal production.

By carefully analyzing these expenses in charcoal production, you can create an accurate charcoal startup budget that paves the way for a successful venture. For further insights into profitability, refer to this guide.

Equipment Purchase (Kilns, Grinders, Packaging Machines)

Securing the right equipment is crucial for a successful charcoal production business. The costs associated with these essential tools can vary significantly based on capacity, technology, and efficiency. Here’s a breakdown of the primary equipment you will need and their associated costs:

| Equipment | Estimated Cost (USD) | Description |

|---|---|---|

| Kilns | $10,000 - $50,000 | Used for the carbonization of raw materials, the kiln type impacts production efficiency. |

| Grinders | $5,000 - $15,000 | Necessary for reducing raw materials into manageable sizes for processing. |

| Packing Machines | $3,000 - $20,000 | Essential for packaging the final product efficiently and professionally. |

The typical costs for charcoal production equipment can range from $18,000 to $85,000, depending on the scale of your operations and choice of equipment. Here’s a closer look at the specific types of equipment you'll need to consider:

- Kilns: These are the core of your operation, where wood or agricultural waste is converted into charcoal. Depending on whether you opt for traditional or modern kilns, the cost can vary widely.

- Grinders: These machines help prepare your raw materials. A good grinder can ensure uniform particle sizes, optimizing the carbonization process.

- Packing Machines: Investing in a reliable packing machine not only saves time but also enhances your product’s marketability. Well-packaged charcoal can attract consumers, potentially increasing sales.

Tips for Reducing Equipment Costs

- Consider purchasing second-hand equipment that meets safety standards to lower initial investment costs.

- Research local suppliers to find competitive prices on essential machinery.

- Negotiate bulk purchasing deals if sourcing multiple pieces of equipment at once.

Moreover, you need to factor in maintenance costs for this equipment. Regular maintenance can help prevent costly breakdowns and prolong the lifespan of your machines. It's advisable to set aside about 10-15% of your equipment investment for maintenance expenses annually.

As you plan your budget, keep in mind that the costs of charcoal production equipment should be detailed in your overall charcoal startup budget. Prioritize acquiring energy-efficient models that can reduce long-term operational costs, which is critical for establishing a sustainable business. For further detailed financial planning and models, you can visit here.

Initial Raw Materials (Agricultural Waste, Additives)

When embarking on a charcoal production business, a significant portion of the startup costs revolves around acquiring initial raw materials. Sustainable charcoal production often utilizes agricultural waste, which not only serves as a primary material but also minimizes environmental impact. This approach aligns perfectly with EcoCharcoals Inc.'s goal of revolutionizing the charcoal industry.

The primary raw materials needed for charcoal production include:

- Agricultural waste (saw dust, coconut shells, rice husks, etc.)

- Additives (binding agents, chemical accelerants)

The cost of these materials can greatly influence the overall charcoal production business costs. For example, the prices can vary based on the source and quality of the materials:

| Material Type | Average Cost per Ton | Notes |

|---|---|---|

| Agricultural Waste | $30 - $70 | Availability varies by region |

| Additives | $50 - $150 | Depends on the type and quantity used |

Utilizing locally sourced agricultural waste not only cuts down on cost analysis of charcoal business but also supports local farmers, thus promoting a circular economy. The carbon footprint of transporting materials can also be reduced significantly by sourcing within a close radius, enhancing sustainability.

Tips for Sourcing Raw Materials

- Build relationships with local farmers or agricultural cooperatives to secure consistent and cost-effective waste supplies.

- Negotiate bulk purchase agreements to lower the price of additives and decrease overall charcoal manufacturing startup expenses.

- Consider alternative raw materials or waste streams that may be underutilized in your area to diversify your supply sources.

In addition to direct material costs, it’s essential to consider the processing of these raw materials. This includes drying, grinding, and preparation for conversion into charcoal. Depending on the scale of production, these processes could add an estimated 20% - 30% to the initial investment in charcoal production.

Effective financial planning for charcoal production startup should account for fluctuations in material prices and availability, as these factors can significantly impact the initial costs of starting a charcoal business. Budgeting effectively and exploring various suppliers can provide a buffer against unexpected price hikes.

Overall, understanding the initial investment in charcoal production necessitates a thorough examination of raw material sourcing. By leveraging the environmental and economic benefits of agricultural waste, businesses like EcoCharcoals Inc. can not only reduce their costs but also enhance their marketability as a sustainable and responsible alternative in the charcoal industry.

Site Acquisition And Preparation (Land Lease Or Purchase)

When embarking on a charcoal production business, one of the significant startup costs to consider is the acquisition and preparation of a suitable site for your operations. Depending on your business model, you may choose to lease or purchase land, both of which contribute significantly to the overall startup costs for charcoal production.

The cost of land can vary widely based on geographical location, size, and whether the land has already been prepared for industrial use. For example, agricultural land suitable for charcoal production typically ranges from $500 to $3,000 per acre, depending on proximity to raw material sources and local infrastructure.

In addition to the cost of land, there are expenses associated with site preparation, which may include:

- Clearing the land of any existing vegetation.

- Grading the land to ensure proper drainage and accessibility.

- Installing necessary infrastructure such as roads, water supply, and waste disposal systems.

- Potential environmental assessments required for compliance with regulations.

On average, the site preparation costs can range anywhere from $5,000 to $20,000, depending on the state of the property and the extent of the preparation needed.

Tips for Cost Management in Site Acquisition

- Research local real estate prices thoroughly to find the best deals on land.

- Consider leasing land initially to reduce upfront costs and evaluate the feasibility of your charcoal manufacturing startup.

- Engage local agricultural partners for potential land share agreements that might lower your costs.

It is essential to factor in charcoal business permits associated with land use in your cost analysis. Depending on your location, you may need various licenses, which can add another $1,000 to $5,000 to your initial investment.

More importantly, having the right site can positively impact your overall operational efficiency. For instance, a well-located site near agricultural waste sources not only reduces transportation costs but can also enhance your production capabilities.

| Cost Item | Lease Cost (Annual) | Purchase Cost (One-Time) |

|---|---|---|

| 1 Acre of Land | $500 - $1,500 | $500 - $3,000 |

| Site Preparation | N/A | $5,000 - $20,000 |

| Permits and Licenses | N/A | $1,000 - $5,000 |

In conclusion, investing time and resources into selecting the right location and preparing it adequately not only minimizes expenses in charcoal production but also sets a strong foundation for sustainable growth. Understanding the cost analysis of your charcoal business will ensure you make informed decisions that enhance the potential for profitability in the long run.

Permits and Licenses (Environmental and Operational)

Starting a charcoal production business involves not just a financial commitment but also a thorough understanding of the legal landscape, particularly concerning permits and licenses. For a business like EcoCharcoals Inc., which focuses on eco-friendly charcoal derived from agricultural waste, navigating through the necessary regulations can be intricate but is crucial for successful operations.

To operate legally and sustainably, you'll need to secure various environmental and operational permits. These might include:

- Environmental Impact Assessments (EIAs): Depending on your location, an EIA may be required to gauge how your production process affects the environment.

- Air Quality Permits: Charcoal production can emit pollutants; thus, obtaining a permit that ensures compliance with air quality standards is essential.

- Waste Management Permits: As a production facility, you may need permits for handling and disposing of waste generated during the charcoal manufacturing process.

- Operational Licenses: These are mandatory governing the overall operation of your business, which can differ based on state and local regulations.

- Health and Safety Permits: Compliance with occupational health and safety standards will require permits to ensure a safe working environment for your employees.

The startup costs for charcoal production can significantly increase if you are not prepared for these legal expenses. For instance, the costs associated with acquiring permits can range from hundreds to thousands of dollars depending on your location and the complexity of your operation. In many cases, the total cost analysis for a charcoal business indicates that legal fees and permits can comprise up to 15-20% of your initial investment.

| Permit Type | Estimated Costs | Time to Acquire |

|---|---|---|

| Environmental Impact Assessment | $1,000 - $5,000 | 1 - 6 months |

| Air Quality Permit | $500 - $2,500 | 1 - 3 months |

| Waste Management Permit | $200 - $1,000 | 1 - 4 months |

| Operational License | $300 - $1,500 | 1 - 2 months |

Tips for Acquiring Permits Efficiently

- Start early: Begin the permitting process as soon as you have a business plan in place to avoid delays in starting production.

- Consult experts: Engaging with a legal professional familiar with your industry can save time and help you navigate complex regulations.

- Stay updated: Regulations can change, so frequently check for updates to ensure compliance.

When evaluating the initial costs of starting a charcoal business, it’s important to consider these legal fees as part of your charcoal startup budget. Investing time and resources into securing the right permits will not only ensure compliance but will also enhance your reputation as a sustainable producer in the market.

Ultimately, understanding the licensure and regulatory process is an essential step for aspiring entrepreneurs in the charcoal manufacturing sector. It's advisable to create a detailed project plan that includes these expenses and timelines, aligning with your broader financial planning for your charcoal production startup. For guidance on budgeting and financial modeling, check out resources that can assist with your charcoal production financial needs: Charcoal Production Financial Model.

Branding And Marketing Expenses (Logo, Website, Promotions)

When starting a **charcoal production business**, branding and marketing expenses play a crucial role in establishing your identity and reaching your target audience. For a company like **EcoCharcoals Inc.**, which aims to promote sustainable and eco-friendly charcoal alternatives, a solid branding strategy is essential. The initial investment in branding can range significantly based on the scope and strategy you choose, but it's pivotal for attracting environmentally conscious consumers.

Your branding strategy should encompass several key areas:

- Logo Design: Creating a professional logo is fundamental. Hiring a graphic designer can cost anywhere from $300 to $2,500 depending on complexity and designer experience.

- Website Development: A well-designed website is critical for online presence. Basic site creation can start around $500, while custom-built solutions may exceed $5,000.

- Promotions: Initial marketing campaigns, including online ads, social media promotions, and local events, can require a budget of at least $1,000 to $5,000.

According to recent studies, businesses that invest in branding can see a return on investment as high as **300%** in terms of customer loyalty and retention. Therefore, allocating adequate funds for branding is not just an expense; it is a strategic investment in your charcoal production business.

Tips for Reducing Branding and Marketing Expenses

- Utilize free tools and platforms for logo design, like Canva or Adobe Spark, to create a basic logo.

- Explore DIY website builders like Wix or Squarespace, which may come at a lower cost compared to hiring a web developer.

- Engage in organic marketing strategies through social media channels, which can be cost-effective compared to paid advertising.

In addition to these initial expenses, ongoing marketing activities are necessary to maintain visibility and engagement in a competitive market. This includes:

- Content Marketing: Creating blogs, newsletters, and social media posts that inform and engage your audience can be done with minimal costs but yields significant results.

- Networking: Participating in trade shows and local community events can enhance visibility for a modest entry fee, sometimes less than $500.

- Promotional Materials: Brochures, business cards, and flyers should be factored into your budget, typically costing between $100 and $1,000 based on quantity and design.

To provide a clearer view of potential costs associated with branding and marketing, consider the following table showcasing an example startup budget breakdown:

| Expense Type | Estimated Cost | Notes |

|---|---|---|

| Logo Design | $500 | Freelance designer |

| Website Development | $1,500 | Custom-built site |

| Initial Marketing Campaigns | $2,000 | Online ads and event participation |

| Promotional Materials | $300 | Brochures and business cards |

| Total Branding and Marketing Costs | $4,600 |

By carefully assessing **startup costs for charcoal production** and making informed decisions about branding and marketing, you can effectively position your business for success. Budgeting wisely in these areas will facilitate better visibility and foster connections with your target audience, ultimately impacting the long-term viability of your charcoal manufacturing venture.

For detailed insights into financial planning and to access comprehensive financial templates for your charcoal production business, visit here.

Legal Fees (Business Registration, Contracts)

Starting a charcoal production business, such as EcoCharcoals Inc., involves navigating various legal requirements that incur significant costs. Understanding these legal fees is crucial to your overall startup costs for charcoal production. The typical legal fees can vary depending on the region and the complexity of your business structure but could range from $1,000 to $5,000 or more.

Here are the main legal expenses you should consider when launching your charcoal production business:

- Business Registration: Registering your business name and structure (e.g., LLC, Corporation) typically costs between $200 and $800, depending on your state regulations.

- Licenses and Permits: Required permits for environmental and operational compliance can range from $500 to $2,000. It's essential to research local regulations to ensure compliance.

- Contracts: Drafting legal contracts for suppliers, buyers, and employees may incur costs from $500 to $3,000, especially if you require a lawyer's assistance.

- Intellectual Property Protection: If you plan to develop unique processes or branding for your charcoal, consider patent filing fees, which can start from $1,500 and go upwards.

The need for thorough legal preparation cannot be overstated, especially in an industry transitioning towards sustainability. Without proper legal frameworks, EcoCharcoals Inc. could face fines or operational halts due to regulatory breaches. Additionally, securing the right permits enhances your credibility in the market.

Tips to Manage Legal Fees

- Consult with a local business attorney to understand your specific legal needs and budget accordingly.

- Utilize online legal services for basic documents and contracts to reduce costs.

- Plan your business structure early to minimize registration and licensing fees.

It's worth noting that some businesses report spending over 15% of their initial investment on legal fees. Understanding this cost aspect is crucial when conducting a cost analysis of your charcoal business.

| Expense Type | Cost Range | Notes |

|---|---|---|

| Business Registration | $200 - $800 | Varies by state |

| Licenses and Permits | $500 - $2,000 | Environmental compliance required |

| Contracts | $500 - $3,000 | Legal assistance may be needed |

For those interested in a detailed financial breakdown, consider leveraging resources that provide comprehensive models. You can access financial planning tools specifically tailored for the charcoal production industry at this link.

Investing time and resources into understanding the legal landscape will not only streamline your startup process but also protect the longevity of your charcoal production endeavors. By budgeting appropriately for these initial legal expenses, you set a solid foundation for cost-effective charcoal manufacturing startup expenses and sustainable growth in the industry.

Utility Setup Costs (Electricity, Water Connection)

When embarking on the journey of establishing a charcoal production business, one crucial aspect that often gets overlooked is the utility setup costs, specifically for electricity and water connections. These are essential for operating machinery and ensuring the production process runs smoothly.

The costs associated with utility setup can vary significantly based on location and the scale of your operation. For a small to medium-sized charcoal manufacturing startup, you might encounter initial expenses like:

- Electricity Connection Fees: These fees can range from $500 to $2,000 depending on the voltage and capacity required for your equipment.

- Water Supply Setup: The cost of connecting to a municipal water supply can range from $300 to $1,500, depending on the distance from the main line and any necessary plumbing.

- Utility Equipment Costs: This includes pumps, filtration systems, and other necessary equipment, which can add another $1,000 to $3,000 to your budget.

These costs can be quite significant when calculating the startup costs for charcoal production. Therefore, it is vital to plan your budget accurately to avoid unexpected expenses that might hinder your production goals.

Tips for Reducing Utility Setup Costs

- Investigate local utility companies for discounts or subsidies that might be available for businesses focused on sustainability.

- Consider installing energy-efficient equipment that may have lower ongoing utility costs, offsetting initial setup expenses over time.

- Check with local government regarding water-saving programs or funding that could assist with the initial connection fees.

In terms of financial planning, it is advisable to allocate around 10-15% of your total startup budget to utility setup costs, particularly if you are looking at a medium-scale production facility. For instance, if your initial investment in charcoal production is projected to be around $50,000, budgeting approximately $5,000 to $7,500 for utilities could provide a cushion for any unexpected expenses.

It's also essential to perform a cost analysis of your charcoal business to ascertain how these utility costs will affect your overall profitability. The utility costs may influence the cost to produce charcoal, ultimately affecting your pricing strategy.

| Utility Type | Estimated Cost | Notes |

|---|---|---|

| Electricity Connection | $500 - $2,000 | Dependent on machinery requirements |

| Water Supply | $300 - $1,500 | Varies by location |

| Utility Equipment | $1,000 - $3,000 | Pumps and filtration systems |

Finally, always keep in mind that as EcoCharcoals Inc. commits to sustainable practices, finding efficient and cost-effective utility solutions not only supports operational efficiency but also aligns with the brand's eco-friendly mission. By addressing these initial utility setup costs early in your planning process, you can position your business for success in the competitive charcoal production market.

Insurance (Property, Liability Coverage)

When starting a charcoal production business, one of the crucial startup costs involves obtaining the right insurance coverage. This not only protects your investment but also ensures compliance with regulations and mitigates financial risks associated with potential operational hazards. The primary types of insurance you should consider are property insurance and liability coverage.

Property insurance is essential as it helps safeguard your physical assets, including charcoal production equipment, facilities, and raw materials from unforeseen events like fire, theft, or natural disasters. Liability coverage, on the other hand, protects your business against claims resulting from injuries or damages caused by your operations or products. In the charcoal industry, where production methods can sometimes pose safety risks, having adequate liability insurance is vital.

Here's a brief overview of estimated costs associated with insurance for your charcoal production startup:

| Type of Insurance | Estimated Annual Cost | Description |

|---|---|---|

| Property Insurance | $1,000 - $3,000 | Covers damage to physical assets. |

| General Liability Insurance | $500 - $2,000 | Protection against third-party claims. |

| Workers' Compensation Insurance | $1,000 - $2,500 | Covers employee injuries. |

Based on industry benchmarks, the average annual insurance costs for a charcoal production business can range between $2,000 and $7,500. This figure may vary depending on factors such as business size, location, and specific operational risks. It is prudent to factor these costs into your charcoal startup budget to ensure comprehensive financial planning.

Tips for Managing Insurance Costs

- Shop around and compare quotes from multiple insurance providers to get the best rates.

- Consider bundling different types of insurance with one provider for potential discounts.

- Regularly review and update your policies as your business grows and evolves.

Moreover, understanding your charcoal production business costs and how they relate to insurance is fundamental. For example, if you're operating a facility with a high risk of fire due to the nature of the materials used, you may need to invest in higher coverage. Conversely, if you implement effective safety measures and risk management practices, there's potential for reduced premiums.

As you navigate through your initial investment in charcoal production, don't overlook the importance of discussing your needs with an insurance advisor who specializes in manufacturing businesses. They can help tailor a policy that aligns with your operational requirements and offers peace of mind as you embark on this sustainable venture with EcoCharcoals Inc..

Initial Labor Costs (Hiring, Training)

Labor costs are a crucial component of the startup costs for a charcoal production business, significantly impacting your overall cost analysis charcoal business. These expenses encompass not only the wages of employees but also the costs associated with hiring and training them. Properly managing initial labor costs is essential to ensure your charcoal manufacturing startup expenses remain within budget.

When accounting for initial labor costs, consider the following factors:

- Wages for skilled labor: It is common to pay around $15 to $25 per hour for skilled laborers who can operate machinery in charcoal production.

- Hiring unskilled labor: Unskilled workers may require an hourly wage between $10 to $15. Their role may include loading raw materials, packaging finished products, and maintaining cleanliness.

- Training programs: Implementing effective training programs can cost an average of $300 to $1,000 per employee, depending on the complexity of the production processes.

- Recruitment expenses: This might include job postings, recruitment agency fees, or background checks, which can sum up to $200 to $1,000 depending on the method used.

Considering these factors, initial labor costs can easily range between $10,000 and $30,000 for the setup of your charcoal production facility, depending on the scale of operations.

| Category | Estimated Cost | Details |

|---|---|---|

| Skilled Labor | $15 - $25/hour | Operators for charcoal production machinery |

| Unskilled Labor | $10 - $15/hour | Loading, packaging, maintenance tasks |

| Training | $300 - $1,000/employee | Effective programs for skills development |

Incorporating a strategic approach to hiring and training can help control costs and enhance productivity. Here are a few tips:

Tips for Managing Initial Labor Costs

- Utilize local training resources or community colleges to provide affordable training programs.

- Consider hiring seasonal workers during peak production periods to manage labor costs effectively.

- Offer performance-based incentives to motivate employees and improve productivity without incurring high fixed labor costs.

Additionally, consider the importance of ongoing training as part of your financial planning for charcoal production startup. A well-trained workforce can lead to increased efficiency, reduced waste, and higher quality products, ultimately impacting the cost to produce charcoal positively.

As you develop your charcoal startup budget, remember that proper financial planning can facilitate smoother operations and minimize unforeseen expenses. Explore funding options through charcoal business financing to cover initial labor costs, enabling you to focus on establishing a successful and sustainable business.

For detailed insights into the financial aspects of launching a charcoal production business, check out this useful resource: Charcoal Production Financial Model.