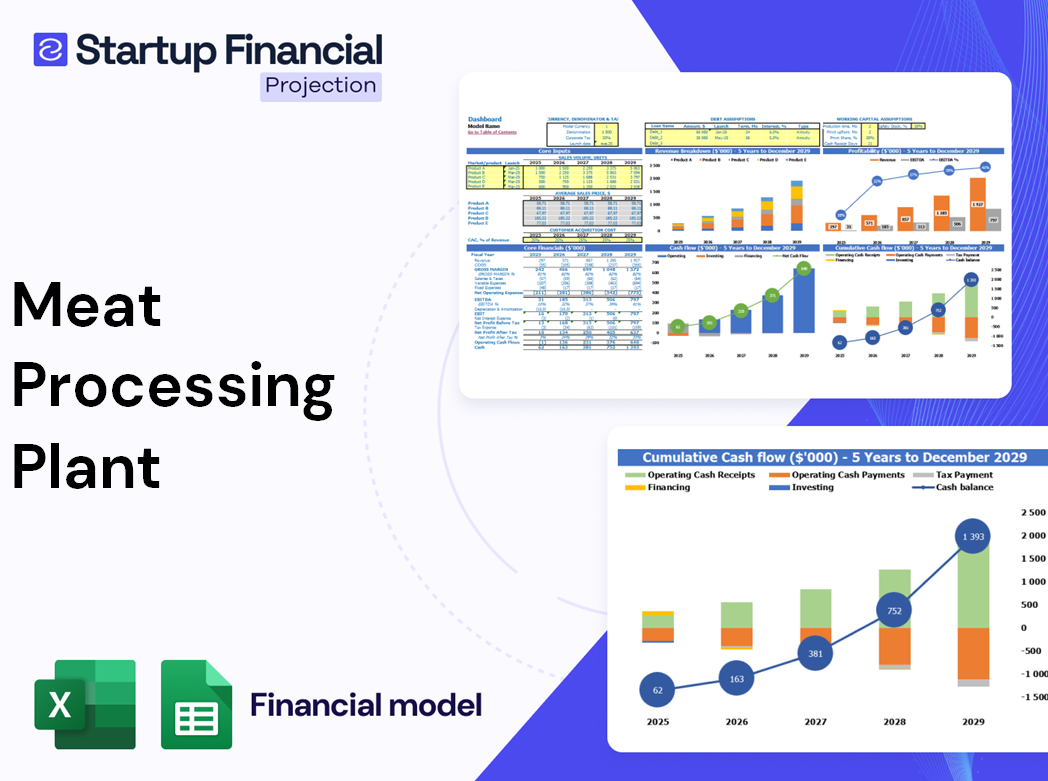

- 5-Year Financial Projection

- 40+ Charts & Metrics

- DCF & Multiple Valuation

- Free Email Support

Related Blogs

Are you ready to dive into the world of meat processing but unsure where to begin? Starting a meat processing plant can be a daunting task, especially if you have no experience or resources. In just 9 simple steps, you can transform your vision into a thriving business. Curious about how to navigate the complexities of regulations, funding, and market strategies? Explore our comprehensive checklist and discover the essential elements to launch your successful meat processing venture. For a detailed blueprint, check out this business plan that can guide you through every crucial phase.

How Do I Open A Meat Processing Plant Company With No Experience?

Starting a meat processing plant business without prior experience may seem daunting, but with the right approach, it is entirely feasible. The key is to equip yourself with knowledge and resources that will help you navigate the complexities of this industry. Here are essential steps to consider:

- Research the Industry: Familiarize yourself with the meat processing regulations, market trends, and consumer preferences. Understanding the dynamics of the industry is crucial for success.

- Find a Mentor: Connect with experienced professionals in the meat processing field. Their insights can provide invaluable guidance and help you avoid common pitfalls.

- Educate Yourself: Consider enrolling in courses related to food safety, meat processing technology, and business management. Websites such as the USDA provide resources on meat processing regulations and standards.

- Develop a Business Model: Outline a clear business model for your meat processing plant. This should include your target market, unique selling propositions, and supply chain logistics.

- Build a Network: Establish relationships with sustainable meat suppliers and other stakeholders in the industry. Networking can open doors to partnerships and opportunities.

- Create a Financial Plan: Develop a detailed financial plan for your meat processing plant that includes budgeting for equipment, facility setup, and operational costs. A well-structured plan can attract investors for your meat processing business.

Tips for Success

- Utilize online resources and forums to connect with others in the industry.

- Consider partnering with someone who has experience in meat processing to complement your skills.

- Stay updated on the latest technology and advancements in meat processing to enhance efficiency.

By following these steps, you can successfully navigate the journey of opening a meat processing company even without prior experience. Remember, preparation and continuous learning are key components to establishing a thriving business in this competitive industry.

How Do I Start A Meat Processing Plant Company With No Money?

Starting a meat processing plant business with no money may seem daunting, but several strategies can help you overcome financial challenges. Here are some actionable steps to consider:

Leverage Partnerships

- Form partnerships with local farmers or meat suppliers who may be willing to share resources in exchange for processing services.

Networking within the meat processing industry can open doors. Attend local agricultural fairs or food expos to identify potential partners who share your vision for sustainable meat production.

Seek Grants and Loans

- Explore government grants specifically aimed at food production and sustainability, which can provide startup capital without the need to repay.

- Investigate low-interest loans from agricultural cooperatives or community banks that support local businesses.

According to the USDA, there are various programs designed to support new agricultural ventures, and many of these include funding opportunities for meat processing startups.

Utilize Shared Facilities

- Consider using shared kitchen or meat processing facilities, which can significantly reduce initial setup costs.

- Look for incubators specializing in food processing that offer resources and mentorship.

Shared facilities can lower your overhead costs and allow you to focus on building a client base without the burden of major expenses. There are numerous meat processing plant startup guides that discuss this approach in detail.

Build an Effective Business Model

- Develop a lean business model that focuses on cost-efficiency and maximizing profit margins.

- Prioritize sourcing sustainable meat suppliers who align with your ethical standards and can provide favorable pricing.

By creating a business model for your meat processing plant that minimizes expenses and maximizes productivity, you can attract potential investors for your meat processing business to help fuel growth.

Tap into Community Resources

- Engage with local chambers of commerce or business associations that may offer funding resources or mentorship programs.

- Consider crowdfunding as a viable option to gather small amounts of money from a larger group of people.

Community support can be instrumental, not just in financial terms, but also in building a customer base that values sustainable production methods.

In conclusion, starting a meat processing plant with limited funds requires creativity and persistence. By leveraging partnerships, seeking grants, utilizing shared facilities, creating an effective business model, and tapping into community resources, you can successfully launch your venture. For more insights on financial aspects, check out this detailed guide on profitability in meat processing.

Example Of Checklist For Opening A Meat Processing Plant Company

Starting a meat processing plant business requires meticulous planning and execution. Below is a checklist to guide you through the essential steps needed to successfully open your plant.

Research and Understand the Regulatory Requirements

Before diving into your business, it's critical to familiarize yourself with the meat processing regulations in your region. Understanding these laws will prevent future legal challenges. Make sure to check:

- Local, state, and federal regulations

- Health and safety standards

- Environmental compliance requirements

Identify and Source Sustainable Meat Suppliers

Partnering with sustainable meat suppliers is vital. This aligns with the growing consumer demand for ethically sourced products. Create a list of local farms and suppliers that meet your sustainability criteria and assess their practices.

Develop a Comprehensive Business Model

Creating a robust business model for your meat processing plant will help define your market, target customers, and operational strategy. Consider the following elements:

- Product range and quality standards

- Target market demographics

- Distribution channels

Create a Detailed Financial Plan and Budget

A solid financial plan for meat processing plant operations is essential for sustainability. Estimate initial costs, operational expenses, and projected revenues. This will guide your financial budgeting for meat processing as well as set realistic goals.

Secure Necessary Funding and Investment

Funding is a critical aspect of your meat processing plant startup guide. Identify different options for raising capital, such as:

- Bank loans

- Investor partnerships

- Crowdfunding platforms

Find a Suitable Location for the Processing Plant

Choosing the right location can significantly impact your operations. Look for areas that provide:

- Proximity to suppliers

- Access to transportation networks

- Compliant zoning laws for food processing

Purchase Equipment and Set Up the Facility

Investing in the right equipment is fundamental. Your plant will need:

- Processing machinery

- Safety and sanitary equipment

- Cold storage facilities

Hire Skilled Staff and Train Employees

Hiring the right team is crucial, particularly in a specialized field like meat processing. Focus on:

- Hiring employees with relevant experience

- Providing comprehensive training programs

- Ensuring compliance with safety regulations

Market the Business and Build a Customer Base

Implementing a strong marketing strategy will position your launch meat processing business for success. Consider leveraging:

- Social media platforms

- Local community outreach events

- Partnerships with restaurants and grocery stores

Tip

- Networking with other professionals in the industry can provide valuable insights and potential partnerships for your starting a meat processing plant.

How Long Does It Take To Start A Meat Processing Plant Company?

Starting a meat processing plant business involves multiple steps, making the timeline for opening a meat processing company quite variable. On average, the entire process can take anywhere from 12 to 24 months. This includes the time needed for planning, securing financing, complying with regulations, and constructing the facility.

The timeline can be broken down into several key phases:

- Research and Planning: 1 to 3 months for market analysis, feasibility studies, and drafting a business model for a meat processing plant.

- Regulatory Approvals: 3 to 6 months to meet meat processing regulations and acquire necessary permits from health and safety authorities.

- Financing: 1 to 4 months to secure a financial plan for the meat processing plant, whether through personal funds or securing investors for a meat processing business.

- Construction and Equipment Setup: 4 to 8 months for the building of the facility and installation of equipment for meat processing plant.

- Hiring and Training: 1 to 3 months for hiring employees for meat processing and implementing training programs.

- Marketing and Launch: 1 month prior to opening for establishing market presence and building customer relationships.

It is crucial to understand that the complexity and scale of the operations can significantly affect the timeline. For instance, if you are starting a small-scale operation, you might navigate through the process more quickly than a large facility aiming for extensive production capabilities.

Tips to Expedite Your Start-Up Timeline

- Engage legal experts early to streamline regulatory requirements for meat processing.

- Consider pre-owned equipment to reduce setup time and costs.

- Build relationships with sustainable meat suppliers during the planning phase to ensure a steady supply from day one.

- Utilize a detailed checklist for starting a meat processing company to keep your project on track.

Ultimately, understanding the timeline for opening a meat processing plant will help you manage your expectations and plan effectively for the successful launch of your business, such as capex considerations that could impact your schedule and budget.

How Can I Find Investors For Starting A Meat Processing Plant Company?

Securing funding is a critical step in launching your meat processing plant business. Properly identifying and approaching potential investors can make or break your startup. To navigate this process effectively, consider the following strategies:

- Develop a Comprehensive Business Plan: A detailed meat processing business plan outlines your vision, objectives, market potential, and financial projections. Currently, investors look for plans that project at least a 15-25% return on investment.

- Utilize Crowdfunding Platforms: Platforms like Kickstarter or Indiegogo can help you raise funds without traditional investors. Successful campaigns in the food sector have raised over $50,000 in just weeks.

- Network in Industry Events: Attend food industry expos and conferences to connect with venture capitalists and angel investors interested in sustainable meat suppliers and innovative processing methods.

- Leverage Online Investor Networks: Use platforms like AngelList to find investors actively seeking opportunities in the meat processing sector. There are around 1,500 active angel investors in the U.S. focusing on food startups.

It’s also essential to be transparent about your startup’s operational costs. For instance, according to industry benchmarks, the average cost to start a meat processing plant can range from $250,000 to $2 million, depending on the scale and location.

Key Tips for Attracting Investors

- Highlight your commitment to sustainability and ethical practices, as these are increasingly appealing to investors who prioritize corporate social responsibility.

- Prepare a solid financial plan for your meat processing plant that covers startup costs, operational expenses, and projected revenues over the first 3-5 years.

- Track industry trends which indicate that the demand for ethically sourced meat is increasing at a rate of 10% annually.

By strategically finding investors for your meat processing business, you can gain the financial support necessary to navigate the regulatory requirements and initial challenges associated with opening a meat processing company. Remember, building relationships and maintaining open communication with potential investors can significantly enhance your chances of securing the needed capital.

How Do I Create A Successful Business Plan For A Meat Processing Plant Company?

Creating a successful business plan for your meat processing plant business is crucial for securing funding and guiding your operations. A strong business plan provides potential investors with insight into your vision and strategy while outlining the steps necessary for success. Here's how to effectively structure your business plan for a meat processing plant.

1. Executive Summary

Your executive summary should succinctly convey the essence of your business. It must include:

- Your business idea, such as EcoMeat Provisions.

- The mission statement focused on sustainability and ethical meat processing.

- A brief overview of the target market and competitive advantage.

2. Market Analysis

Research is key in this section. Analyze industry trends, target demographics, and market demands. Highlight the growing consumer interest in responsibly sourced meat, noting that the global organic meat market is expected to reach $12.69 billion by 2027 with a CAGR of 14.4% from 2020.

3. Business Model

Detail your business model for the meat processing plant, focusing on:

- Types of meat processed.

- Sales channels (wholesale, retail, online).

- Partnerships with sustainable meat suppliers.

4. Regulatory Requirements

Compliance with meat processing regulations is critical. Outline the necessary permits and licenses needed to operate legally, emphasizing food safety standards, environmental regulations, and worker safety guidelines.

5. Marketing Strategy

Your marketing strategy should engage your target audience effectively. Consider:

- Branding focused on sustainability and quality.

- Digital marketing campaigns, including social media outreach and content marketing.

- Collaborations with local farms and health organizations.

6. Financial Plan

Develop a detailed financial plan for your meat processing plant, including:

- Start-up costs (equipment, facility setup, initial inventory).

- Projected revenue and cash flow for the first 3-5 years.

- Break-even analysis to determine how long it will take to become profitable.

Resources such as these: financial modeling templates can be beneficial in outlining this section.

7. Operations Plan

This section should detail the day-to-day operations of your facility, including:

- Staffing needs and the hiring employees for meat processing.

- Training programs to ensure compliance with safety and quality standards.

- Supply chain management strategies.

8. Funding Requirements

Clearly state how much funding you need and how you plan to use it. This should include:

- Initial startup costs, operational costs, marketing expenses.

- Details on potential investors for your meat processing business.

- Options for securing investment, including grants and loans.

9. Appendices

Include any additional documents that support your business plan, such as:

- Market research data.

- Detailed financial projections.

- Resumes of key team members.

Key Tips for a Solid Business Plan

- Be realistic in your financial projections and provide a range of outcomes.

- Seek feedback from industry experts before finalizing your plan.

- Regularly update your plan as your business grows and market conditions change.

Checklist For Opening A Meat Processing Plant Company

When considering how to start a meat processing plant, a thorough checklist is essential for navigating the complexities of this industry. Here’s a comprehensive checklist to guide you through the process:

Research And Understand The Regulatory Requirements

Familiarize yourself with federal, state, and local meat processing regulations. Compliance is crucial, and different regions may have varying requirements.

Identify And Source Sustainable Meat Suppliers

Establish relationships with sustainable meat suppliers who prioritize ethical sourcing. This could enhance your brand's reputation and meet consumer demand effectively.

Develop A Comprehensive Business Model

Create a viable business model for meat processing plant. It should outline your target market, value proposition, and sales strategies to ensure profitability.

Tip for Business Model Development

- Consider integrating a farm-to-table approach to appeal to environmentally conscious consumers.

Create A Detailed Financial Plan And Budget

Your financial plan for meat processing plant should include startup costs, operational costs, and projected revenue. Allocate funds wisely to cover equipment, staffing, and marketing.

Secure Necessary Funding And Investment

Look for investors for meat processing business, such as venture capitalists or government grants designed for sustainable enterprises. Formulate a compelling pitch to attract potential investors.

Find A Suitable Location For The Processing Plant

Choosing the right location is essential. Ensure it is accessible to suppliers and customers, adheres to zoning regulations, and has room for future expansion.

Purchase Equipment And Set Up The Facility

Invest in high-quality equipment for meat processing plant. The initial investment can range from $250,000 to over $1 million depending on the scale of your operations.

Hire Skilled Staff And Train Employees

Recruit experienced personnel for various roles within your plant. Adequate training employees in meat processing is crucial to maintain high standards and efficiency.

Market The Business And Build A Customer Base

Create a robust marketing strategy. Utilize digital marketing, local advertisements, and partnerships with restaurants and retailers to increase visibility and attract customers.

Marketing Tips

- Leverage social media to share your sustainability story and engage with your community.

Following this starting a meat processing business checklist will help ensure that your venture is set up for success, allowing you to meet the growing demand for quality, ethically sourced meat in a competitive market.

Research And Understand The Regulatory Requirements

Starting a meat processing plant business involves navigating a complex web of regulations. Understanding these meat processing regulations is crucial to ensure compliance and prevent costly delays. Different regulations may apply depending on your location, and local, state, and federal guidelines must be factored in. Here are key areas of focus:

- Food Safety Regulations: The USDA (United States Department of Agriculture) enforces strict food safety standards. Familiarize yourself with the standards set forth in the Federal Meat Inspection Act (FMIA) and the Meat Inspection Regulations.

- Licensing and Permits: A variety of licenses and permits may be required at the local and state levels to operate a meat processing facility legally.

- Hazard Analysis Critical Control Point (HACCP) Plan: Developing and implementing a HACCP plan is essential, as it helps identify and control food safety hazards during production.

- Environmental Regulations: Compliance with environmental regulations, including waste management and pollution control, is necessary to minimize the ecological impact of your processing operations.

Before diving into the establishment of your meat processing plant, consider conducting a thorough review of the regulatory landscape. This may include seeking guidance from industry experts or legal advisors who specialize in food processing regulations. The following table outlines some typical regulations and the corresponding authorities:

| Regulation | Authority | Notes |

|---|---|---|

| Federal Meat Inspection Act (FMIA) | USDA | Ensures meat products are safe and sanitary. |

| State Licensure Regulations | State Departments of Agriculture | Vary by state; ensure local compliance. |

| Environmental Protection Agency (EPA) Regulations | EPA | Focus on waste management and pollution controls. |

Tips for Navigating Regulatory Requirements

- Establish a regulatory compliance team to stay updated on changing laws.

- Attend workshops and training sessions focused on meat processing regulations.

- Consult with a legal expert to help navigate complex regulations and avoid fines.

Additionally, it's important to note that violations can lead to significant penalties, including fines that may range from $1,000 to $10,000 or more per incident, depending on the violation's severity. Ensuring compliance from the outset is essential to avoid these pitfalls and maintain a solid reputation in the market.

For those considering opening a meat processing plant with sustainable practices in mind, it would be beneficial to delve into specific guidelines surrounding sustainable meat suppliers and ethical sourcing. Understanding the regulatory environment around these practices enhances your business model for the meat processing plant.

Developing a comprehensive understanding of these regulatory requirements will not only help you avoid regulatory issues but will also provide an opportunity to market your business as one that prioritizes compliance, quality, and safety—factors that resonate with consumers today. Consider leveraging this knowledge in your meat processing business plan for a fortified strategy going forward. For further insights into financial planning, explore resources like this financial model tailored for meat processing plants.

Identify And Source Sustainable Meat Suppliers

As you embark on the journey to start your meat processing plant, identifying and sourcing sustainable meat suppliers is a critical step. A focus on sustainability not only attracts environmentally-conscious consumers but also ensures compliance with current meat processing regulations. In fact, according to a report by the Food and Agriculture Organization (FAO), about 70% of consumers are willing to pay more for sustainably sourced products. Thus, finding the right suppliers is essential for establishing a reputable business model.

Begin by researching local farms and suppliers that prioritize ethical animal husbandry and environmental stewardship. Consider the following factors in your search:

- Certifications: Look for suppliers with certifications such as Animal Welfare Approved, Certified Humane, or USDA Organic.

- Transparency: Choose suppliers that are open about their sourcing practices and treatment of animals.

- Commitment to sustainability: Prioritize suppliers that use sustainable practices, such as rotational grazing or antibiotic-free livestock.

It is also beneficial to network within industry associations focused on sustainable meat production. This can provide you with valuable contacts and insights into reliable sources. For instance, joining organizations like the Sustainable Food Trust or the American Grassfed Association can enhance your credibility and support your mission.

Tips for Sourcing Sustainable Meat Suppliers

- Conduct site visits to potential suppliers to verify their practices.

- Establish long-term relationships with suppliers who are aligned with your values.

- Consider sourcing from cooperatives or local agricultural networks that promote sustainability.

Utilizing a comprehensive business model for your meat processing plant is vital. An effective way to manage relationships with suppliers is by creating a supplier evaluation checklist, which includes:

| Criteria | Importance (1-5) | Notes |

|---|---|---|

| Animal Welfare Standards | 5 | Must meet highest standards |

| Sourcing Practices | 4 | Local and sustainable sources |

| Pricing and Terms | 3 | Competitive yet fair pricing |

Furthermore, leveraging technology can streamline your sourcing process. Tools such as supply chain management software can help track suppliers, manage contracts, and ensure compliance with the necessary regulations. This can be particularly advantageous in the meat processing sector, where adherence to standards is crucial for operational success.

It's also prudent to stay informed about the latest trends in the meat industry. For instance, a 2021 survey revealed that more than 50% of consumers are increasingly concerned about the environmental impacts of meat production. Adapting your sourcing strategies in response to this demand can help position your meat processing plant business as a leader in sustainability.

Implementing these strategies will not only enhance the integrity of your meat processing business plan but also align your operations with consumer expectations and regulatory requirements. For more detailed financial projections related to sourcing and operational costs, consider utilizing a financial model for your meat processing plant.

Develop A Comprehensive Business Model

Creating a successful meat processing plant business requires a well-structured and comprehensive business model. This model not only guides the initial launch but also ensures sustainability and growth in a competitive market. For EcoMeat Provisions, our vision is to lead the way in sustainable meat processing by focusing on quality, transparency, and environmental responsibility.

When developing your business model for a meat processing plant, consider the following essential components:

- Market Research: Identify target customers, including restaurants, grocery stores, and direct consumers interested in sustainable meat options. Analyze market trends to determine pricing and product positioning.

- Value Proposition: Clearly define what makes your processing plant unique. For instance, EcoMeat Provisions emphasizes ethically sourced, sustainably raised meat, appealing to health-conscious consumers.

- Revenue Streams: Establish various avenues for income, such as bulk sales to retailers, online direct sales, and value-added products like marinated meats or ready-to-cook meal kits.

- Cost Structure: Outline all necessary expenses, including sourcing from sustainable meat suppliers, equipment purchases, and operational costs. According to industry benchmarks, the average startup cost for a meat processing plant varies but can range from $500,000 to $5 million, depending on size and technology.

- Supply Chain Management: Develop a strategy for sourcing quality meat from sustainable suppliers. This ensures consistent quality and adherence to meat processing regulations.

- Marketing Strategy: Create a robust marketing plan that emphasizes your commitment to sustainability. This can include social media campaigns, partnerships with local farms, and community outreach.

- Operations Plan: Detail the day-to-day processes of the plant, focusing on efficiency, quality assurance, and regulatory compliance. Consider implementing technology to streamline operations and reduce waste.

- Financial Projections: Project your revenues and expenses for at least the first three years. This should include a comprehensive financial plan for your meat processing plant, detailing break-even analysis and anticipated profit margins.

As you formulate your business model, leverage real-life data to inform your decisions. For instance, the meat processing industry has seen a growth rate of approximately 3% annually due to increasing consumer awareness about health and sustainability. Highlighting these statistics in your business plan can attract investors for your meat processing business.

| Cost Category | Estimated Cost | Percentage of Total Costs |

|---|---|---|

| Equipment Purchase | $200,000 | 40% |

| Facility Setup | $150,000 | 30% |

| Sourcing Meat | $100,000 | 20% |

| Marketing and Sales | $50,000 | 10% |

Tips for Developing a Business Model

- Engage with potential customers early to gather feedback on what they value in a meat processing supplier.

- Consider sustainability certifications to enhance your brand’s credibility and appeal.

- Evaluate your competition to identify gaps in the market that you can fill with your unique offerings.

Lastly, to create a detailed meat processing business plan, consider using resources such as this financial model template to help project your financial needs and secure necessary funding. A solid understanding of your business model will position EcoMeat Provisions for success in a rapidly evolving industry.

Create A Detailed Financial Plan And Budget

Creating a financial plan for your meat processing plant is one of the most critical steps in launching a successful business. A well-structured budget not only helps you understand the costs involved but also positions you to attract potential investors for your meat processing business. Here are essential elements to consider when crafting your financial plan:

- Startup Costs: Determine your initial investment requirements. This includes equipment, facility renovations, licenses, and permits, which can total anywhere from $250,000 to $500,000 depending on your location and scale.

- Operational Costs: Estimate monthly operating expenses, including utilities, labor, and supplies. Typically, expect these costs to be around $30,000 to $50,000 per month for a medium-sized processing plant.

- Revenue Projections: Analyze market trends and set realistic revenue targets. The average meat processing plant can generate between $1 million to $5 million annually, depending on the product offerings and market demand.

- Break-even Analysis: Identify the point at which your revenues will cover your costs. This is essential for understanding how long it will take before your meat processing plant business becomes profitable.

Another key component of your financial planning involves understanding meat processing regulations, which can impact your startup costs significantly. Ensure your budget accounts for any potential fines or additional costs associated with compliance issues.

Tips for Financial Budgeting

- Research industry benchmarks to validate your financial assumptions.

- Consider seeking professional advice for complex financial models to ensure accuracy and foresight.

- Always have a contingency fund of at least 10% of your total budget for unforeseen expenses.

To create an accurate financial model tailored to your business, utilize resources such as the Meat Processing Plant Financial Model, which can guide you through the detailed calculations necessary for a strong business foundation.

| Category | Estimated Cost (Low) | Estimated Cost (High) |

|---|---|---|

| Startup Costs | $250,000 | $500,000 |

| Monthly Operating Costs | $30,000 | $50,000 |

| Annual Revenue | $1,000,000 | $5,000,000 |

In summary, developing a comprehensive financial plan is vital for the successful launch of your meat processing plant. By thoroughly understanding your costs, revenue projections, and regulatory requirements, you're better positioned to make informed decisions that will drive your business towards success.

Secure Necessary Funding And Investment

Launching a meat processing plant business requires significant financial resources. To ensure a successful start, it is crucial to explore various funding options that can support your venture. Start by assessing your financial needs through a well-structured financial plan for meat processing plant which details your estimated costs, including equipment, facility setup, regulatory compliance, and operational expenses.

Consider these common sources for securing funding:

- Personal Savings: Utilize your savings as initial capital that can demonstrate your commitment to potential investors.

- Bank Loans: Approach financial institutions with a solid meat processing business plan to secure loans. Institutions often look for thorough plans that outline risk management and revenue projections.

- Investors: Seek investors for meat processing business who are interested in sustainable practices. Highlight your focus on quality and transparency to attract like-minded partners.

- Grants: Research federal and state grants aimed at promoting agricultural development, which may cover part of your startup costs.

- Crowdfunding: Platforms like Kickstarter or GoFundMe can be used to market your vision and gather small investments from individuals who believe in your concept.

It’s also wise to prepare for a timeline for opening a meat processing plant. Investors typically want to see a clear roadmap and realistic milestones for profitability.

Funding Tips

- Build a compelling pitch that showcases your unique value proposition, emphasizing sustainability and quality.

- Network within the agricultural and food processing communities to find potential angel investors or venture capitalists.

- Ensure all financial projections are based on realistic data, including operational benchmarks, to enhance credibility.

To better understand the financial landscape, consider these key benchmarks:

| Funding Source | Average Amount | Typical Interest Rate |

|---|---|---|

| Bank Loans | $50,000 - $500,000 | 4% - 10% |

| Angel Investors | $25,000 - $250,000 | Variable |

| Crowdfunding | $1,000 - $100,000 | N/A |

In your search for funding, keeping track of the sourcing meat suppliers you plan to work with can also be attractive to investors. Highlighting relationships with sustainable meat suppliers not only enhances your business model for meat processing plant but also appeals to environmentally conscious investors.

Finally, it's important to maintain flexibility in your funding approach. 73% of successful startups report needing multiple funding rounds before reaching profitability, so be prepared to revisit your strategy as your meat processing plant startup guide evolves.

Find A Suitable Location For The Processing Plant

Choosing the right location for your meat processing plant is a critical factor that can significantly influence the success of your business. The location impacts logistics, regulatory compliance, access to sustainable meat suppliers, and the overall operational efficiency of your meat processing plant business.

Here are some essential considerations when selecting a site for your processing facility:

- Proximity to Suppliers: Being close to sustainable meat suppliers can minimize transportation costs and ensure fresher products. Look for locations near livestock farms or areas with high agricultural activity.

- Access to Major Transportation: A site near highways, railroads, or ports can facilitate efficient distribution of your products, making it easier to reach customers and distributors.

- Strategic Market Positioning: Analyze the demand for meat products in your target market. Choosing a location with a high concentration of potential customers can boost your business's sales.

- Regulatory Compliance: Ensure the location complies with all local meat processing regulations. This includes zoning laws and health department regulations, which may vary significantly between regions.

- Utilities and Infrastructure: Access to necessary utilities like water, electricity, and waste management systems is essential for running a meat processing plant efficiently.

- Labor Availability: Consider the availability of skilled labor. A location that offers a workforce with experience in meat processing can reduce the time and resources spent on hiring employees for meat processing.

Tips for Selecting Your Location

- Conduct a comprehensive market analysis to understand the meat consumption patterns in various regions.

- Engage with local government agencies to ensure all regulatory requirements for meat processing are met.

- Consider environmental factors such as waste disposal implications and the impact on surrounding communities.

To illustrate the importance of location, consider these statistical insights:

| Location Factor | Impact on Cost (%) | Potential Revenue Increase (%) |

|---|---|---|

| Proximity to Suppliers | 15% | 20% |

| Access to Transport | 10% | 30% |

| Market Demand | 5% | 50% |

As you evaluate potential sites, remember that the overall success of your meat processing plant startup will depend on how well you balance these factors. Additionally, keep in mind that developing a solid business plan for a meat processing plant can provide clarity on costs and operational needs, which can further guide your location decision.

Ultimately, investing time and resources into finding the right location will pay off in the long run, making it one of the most critical aspects of your journey in starting a meat processing plant. For a detailed financial plan that can help you better understand costs associated with your chosen location, check out this resource: Financial Model for Meat Processing Plant.

Purchase Equipment And Set Up The Facility

When embarking on your journey to launch a meat processing plant business, one of the crucial steps is the acquisition of equipment and the establishment of your facility. This phase requires a careful balance of quality, efficiency, and compliance with meat processing regulations.

First, you need to identify the essential equipment necessary for your operations. Each piece plays a pivotal role in ensuring that your plant runs smoothly and adheres to the highest standards of hygiene and safety. The following is a list of key equipment you will need:

- Processing machines (slicers, grinders, and mixers)

- Packaging machinery

- Refrigeration units

- Cold storage facilities

- Cleaning and sanitizing equipment

- Waste disposal systems

Investing in high-quality, reliable equipment can significantly impact your operational efficiency and product quality. For example, modern meat grinders with advanced technology can reduce processing time by up to 30%, improving your overall productivity.

Once you have identified and sourced your equipment, it's essential to set up the facility in a manner that promotes efficiency and compliance with health standards. Here are some tips to consider:

Tips for Setting Up Your Facility

- Design the layout to minimize contamination risks by placing meat processing areas away from waste disposal areas.

- Invest in high-quality ventilation systems to maintain air quality.

- Ensure that your facility design includes designated zones for raw and finished products to prevent cross-contamination.

When selecting a location for your meat processing plant, consider factors such as proximity to sustainable meat suppliers and access to transportation networks. A strategic location can lead to reduced logistics costs and improved supply chain efficiency.

The financial impact of your equipment choices should not be overlooked. It is advisable to allocate around 15-20% of your startup budget to purchasing necessary equipment. To assist with the financial planning, a detailed financial model tailored for meat processing plants can help track expenses and forecast future profits effectively.

Here’s a benchmark table that can assist you in understanding the average costs associated with the establishment of a meat processing facility:

| Equipment Type | Average Cost | Estimated Lifespan |

|---|---|---|

| Processing Machines | $50,000 - $150,000 | 10 - 15 years |

| Refrigeration Units | $20,000 - $100,000 | 15 - 20 years |

| Packaging Machinery | $30,000 - $80,000 | 10 - 15 years |

As you move forward with purchasing equipment and setting up your facility, remember that quality and efficiency will define your meat processing plant's reputation. This careful planning and execution will lay a solid foundation for your business's success in the competitive market of ethically sourced meat.

Hire Skilled Staff And Train Employees

When launching a meat processing plant business, one of the most critical steps is hiring skilled staff and effectively training employees. The quality of your workforce can significantly impact operations, product quality, and compliance with meat processing regulations. A well-trained team is essential to uphold the ethical standards and sustainability that EcoMeat Provisions is committed to.

Start by identifying key roles that need to be filled:

- Plant Manager

- Quality Control Supervisor

- Butchers and Meat Technicians

- Safety Compliance Officers

- Sales and Marketing Personnel

According to industry studies, companies that invest in training see a 24% higher productivity rate on average. Employees who undergo rigorous training are also 30% more likely to perform their tasks efficiently while adhering to safety protocols.

Next, consider the qualifications and experience needed for each role. For instance, having a certified quality control supervisor familiar with the essential regulatory requirements for meat processing can help mitigate risks of compliance issues. Similarly, hiring skilled butchers who understand sustainable meat sourcing can enhance your operational integrity.

| Role | Key Responsibilities | Qualifications |

|---|---|---|

| Plant Manager | Oversee daily operations, ensure compliance | Degree in Food Science or related field |

| Quality Control Supervisor | Conduct inspections, implement safety protocols | Certification in Quality Control |

| Butchers | Prepare meat, manage processing equipment | Experience in meat handling |

Once you’ve recruited your staff, implement a comprehensive training program that covers:

- Meat handling safety and hygiene

- Understanding of sustainable practices

- Equipment operation and maintenance

- Quality control processes and standards

Training Tips

- Utilize mentorship programs where experienced employees train new hires.

- Incorporate hands-on practice to reinforce theoretical knowledge.

- Regularly update training materials to reflect the latest industry standards.

Moreover, establish a culture of ongoing learning and development. Regular workshops and seminars can keep employees abreast of the latest trends and practices in the meat processing industry. This approach not only enhances employee skills but also boosts morale and retention rates—critical factors in maintaining a talented workforce.

Investing in hiring employees for meat processing and their continuous training is key to the success of your meat processing plant. A skilled team ensures high product quality, safety compliance, and sustainable practices, which aligns perfectly with our vision at EcoMeat Provisions.

For those interested in understanding the financial aspects and operational requirements when starting a meat processing plant, check out our detailed meat processing business plan.

Market The Business And Build A Customer Base

Successfully launching a meat processing plant business hinges significantly on how effectively you can market the business and build a customer base. In today’s competitive landscape, a well-rounded marketing strategy tailored to your target audience is essential. For a company like EcoMeat Provisions, which aims to emphasize sustainability and ethical sourcing, aligning your marketing efforts with these values will resonate strongly with potential customers.

To kickstart your marketing efforts, consider the following key strategies:

- Brand Positioning: Establish EcoMeat Provisions as a premium, eco-friendly provider of meat products. Highlight your commitment to sustainable practices and ethical sourcing in all communications.

- Online Presence: Develop a professional website that showcases your offerings, values, and the process behind your sustainable practices. Invest in SEO strategies to improve visibility in search results for terms like “how to start a meat processing plant” and “sustainable meat suppliers.”

- Social Media Marketing: Utilize platforms like Instagram and Facebook to share visually appealing content about your products, farm partnerships, and behind-the-scenes operations. Engage with the community to build trust and loyalty.

- Local Outreach: Establish partnerships with local businesses, restaurants, and health food stores that align with your values. Consider hosting tasting events or pop-up markets to introduce your products directly to consumers.

- Customer Feedback: Implement methods for gathering customer feedback to improve your offerings and customer experience. This can include surveys, online reviews, and social media engagement.

You may also want to consider various advertising strategies, which might include:

- Content Marketing: Create informative blog posts or videos regarding meat processing, cooking tips, and sustainability. This positions EcoMeat Provisions as an authority in the meat processing field and helps engage potential customers.

- Promotional Offers: Attract initial customers with discounts or bundles, encouraging them to try your products. A “first purchase” promotional offer could help build your customer base.

Tips for Effective Marketing

- Leverage email marketing to keep interested consumers updated on new products and promotions.

- Form alliances with local farms to co-market products and share resources.

- Participate in community events to enhance your brand's visibility and connect with your target audience.

According to recent industry statistics, the global meat processing market is projected to grow at a CAGR of 4.5% from 2021 to 2026. This growth indicates a rising demand for quality meat products, particularly those that adhere to sustainable practices. By showcasing your adherence to meat processing regulations and the ethical treatment of animals, EcoMeat Provisions can capitalize on this trend.

Building a loyal customer base will not happen overnight; however, consistent, strategic marketing can significantly shorten your timeline for opening a meat processing plant and establishing a successful business. Focus on creating a business model for your meat processing plant that emphasizes quality, sustainability, and community engagement.

| Marketing Strategy | Estimated Cost | Expected ROI |

|---|---|---|

| Online Advertising | $5,000 | 3x |

| Local Outreach Events | $2,000 | 4x |

| Content Production (Blogs, Videos) | $1,500 | 5x |

By applying these marketing tactics and tracking their effectiveness, you can ensure that your meat processing plant startup guide includes a comprehensive approach to engaging your market. Building a strong, loyal customer base will be crucial for long-term sustainability and growth in the industry.