Related Blogs

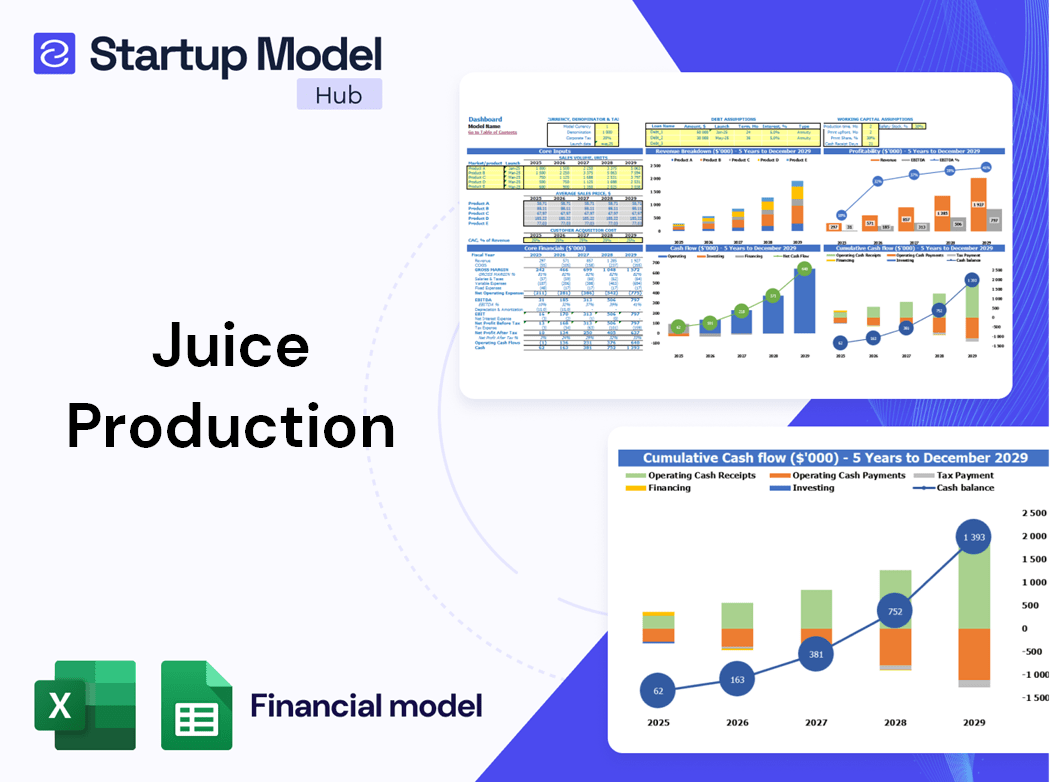

Are you curious about the top nine startup costs for launching a juice production business? Understanding these essential expenses can significantly impact your success. From equipment to raw ingredients, each factor plays a crucial role in your financial planning. Discover how to navigate these costs effectively and set yourself up for profitability by exploring our detailed business plan here: Juice Production Financial Model.

How Much Does It Cost To Start A Juice Production Business?

Starting a juice production business like FreshSqueeze Naturals involves several startup costs that can vary widely based on location, scale, and business model. On average, the total cost to start a juice business can range from $50,000 to $150,000. This cost encompasses various essential expenses that are crucial for launching a successful operation.

Here’s a breakdown of the primary juice business expenses:

- Cold-Pressed Juicer and Equipment: Investing in quality juice production equipment is vital. Expect to spend between $10,000 to $50,000 on juicers, blenders, and other machinery.

- Raw Ingredients and Inventory: Depending on your sourcing strategy and volume, raw ingredients can cost around $2,000 to $10,000 for initial inventory.

- Packaging Materials: Packaging is critical for branding and preservation. Budget around $1,000 to $5,000 for bottles, labels, and other materials.

- Licensing and Permits: Obtaining the necessary permits can set you back $500 to $5,000, depending on your location and regulatory requirements.

- Branding and Marketing Costs: To penetrate the market, allocate around $3,000 to $15,000 for marketing strategies, including logo design and advertising.

- Rent or Lease for Production Facility: Rental costs can vary significantly, but expect to pay between $1,000 to $5,000 monthly, based on the facility's size and location.

- Utility Setup Costs: Setting up utilities may require an initial investment of $500 to $2,000.

- Insurance Coverage: Insurance is essential for protecting your business, costing approximately $1,000 to $3,000 annually.

- Professional Services (Legal, Accounting): Hiring professionals for legal and accounting services can run between $1,000 to $5,000 during the startup phase.

In total, the startup costs for a juice business can add up quickly, but understanding where your money goes is crucial for effective financial planning.

Tips for Minimizing Juice Business Costs

- Consider purchasing used or refurbished equipment to cut down on initial investments.

- Negotiate bulk purchasing agreements with local suppliers to reduce raw ingredient costs.

- Utilize social media and grassroots marketing strategies to lower your marketing budget.

For a more detailed cost breakdown for juice business operations, exploring resources such as this article can provide additional insights into effective budgeting strategies.

Is it Possible to Start a Juice Production Business with Minimal Investment?

Starting a juice production business, such as FreshSqueeze Naturals, can indeed be approached with minimal investment, provided you are strategic about your juice production business costs. The average cost to start a juice business ranges between $10,000 to $50,000, depending on the scale and the market. However, with careful planning, you can significantly reduce these startup expenses for juice production.

One of the most effective ways to minimize your juice business expenses is by sourcing raw ingredients locally. This not only supports the community but can also decrease transportation costs. Moreover, choosing to start with a smaller production scale or even a home-based setup can drastically lower startup costs for juice business.

Consider the following tactics to start your juice production business on a budget:

Tips to Minimize Costs

- Utilize rented or shared kitchen spaces to lower the cost of renting a dedicated facility.

- Invest in affordable juice production equipment or consider buying used machinery to save money.

- Focus on an effective marketing strategy using social media and community events instead of traditional advertising.

- Negotiate with suppliers for better prices on packaging materials and raw ingredients.

In terms of creating a juice production startup budget, prioritize essential expenses. A detailed cost breakdown for juice business should include:

- Equipment costs: Look for affordable options or second-hand equipment.

- Licensing fees for juice production: Research local regulations to minimize permit expenses.

- Marketing budget for juice business: Start small with grassroots marketing efforts.

Statistical data shows that startups with a clear financial plan for juice production can increase their chances of success by over 30%. Writing a comprehensive business plan helps to define your goals while keeping your juice business financing options in check. Whether through bootstrapping or seeking small business loans, ensure that your investment strategies align with your budget.

By keeping an eye on your startup expenses for juice production and utilizing the right resources, it's entirely feasible to launch your juice brand with a minimal initial investment. The growth potential in this sector, driven by consumer demand for healthier beverage options, only adds to the viability of starting a juice production business under budget constraints.

Which Costs Can Be Reduced For A Juice Production Business?

Starting a juice production business like FreshSqueeze Naturals involves a range of startup costs that can quickly add up. However, some expenses can be minimized or optimized to make your juice business more financially viable. Here’s a breakdown of costs that can be reduced:

- Equipment Investment: While purchasing high-quality juice production equipment is essential, consider leasing or buying used machinery to cut **juice production equipment investment** costs. This approach can save you up to **30%** compared to new equipment prices.

- Raw Ingredients Cost: By sourcing ingredients locally and in bulk, you can significantly reduce **raw ingredients cost**. Establish relationships with farmers and local suppliers to negotiate better prices, potentially saving between **15-25%** on ingredient costs.

- Packaging Expenses: Invest in eco-friendly yet affordable packaging solutions. Research and partner with suppliers who offer discounts for bulk orders, which can help lower your **packaging expenses for juice** by as much as **20%**.

- Marketing Budget: Rather than spending heavily on traditional advertising, utilize social media and grassroots marketing strategies that cost less yet can yield high engagement. This could lower your **marketing budget for juice business** by **50%** or more.

- Renting a Production Facility: Starting small can keep your rent costs lower. Consider shared commercial kitchen spaces or co-working facilities designed for food businesses, which can reduce your **startup expenses for juice production** by **40-60%**.

Tips for Reducing Juice Production Costs

- Conduct a thorough market analysis to identify the best suppliers for ingredients and equipment, ensuring you get the most competitive prices.

- Implement a just-in-time inventory system to reduce storage costs related to ingredients and packaging materials.

- Utilize social media platforms to market your products effectively and at a lower cost than traditional media.

By focusing on these areas, you can optimize your **startup costs for juice business** and develop more effective **juice business financing** strategies, ultimately increasing the sustainability and profitability of your venture. Reviewing your financial plan actively to pinpoint potential savings is crucial for long-term success.

Examples of Startup Budgets for Juice Production Businesses

Starting a juice production business like FreshSqueeze Naturals requires careful planning and a clear understanding of the juice production business costs. Here’s a detailed breakdown of potential startup budgets to give you a sense of the financial commitment involved.

Estimated Startup Budget

The following example outlines a projected budget for a small-scale juice production business:

- Cold-Pressed Juicer and Equipment: $10,000 - $25,000

- Raw Ingredients and Inventory: $5,000 - $15,000

- Packaging Materials: $2,000 - $5,000

- Licensing and Permits: $1,000 - $3,000

- Branding and Marketing Costs: $2,500 - $7,500

- Rent or Lease for Production Facility: $1,500 - $3,000/month

- Utility Setup Costs: $1,500 - $2,500

- Insurance Coverage: $800 - $2,000 annually

- Professional Services (Legal, Accounting): $1,000 - $3,000

In total, the estimated startup costs for juice business can range between $25,000 to $72,000 for a small to medium-sized operation, depending on the scale and quality of the equipment and resources.

Cost Breakdown for Juice Business

It’s essential to have a detailed cost breakdown for juice business expenditures. For instance, high-quality juice production equipment can significantly impact your initial investment. By opting for refurbished or used machinery, one could potentially save up to 30% on equipment costs.

Tips for Budget Management

- Consider starting with a smaller production run and gradually scale up as demand grows.

- Utilize local suppliers to reduce raw ingredients costs and support community businesses.

- Explore collaborative marketing strategies with local gyms or health food stores to share costs.

Ultimately, securing financing is a crucial aspect of launching your juice production startup. Many business owners explore options such as juice business financing through personal savings, loans, crowdfunding, or investment from friends and family. Understanding your startup expenses for juice production will help you present a solid case to potential investors.

Additionally, you can check resources such as this article on opening a juice production business to gain insights on budgeting and operational costs.

Whether you aim for an affordable juice production model or seek extensive investment strategies, detailed financial planning is essential for sustainability and growth in the competitive juice market.

How to Secure Enough Funding to Start a Juice Production Business?

Securing adequate funding is a critical step when launching a juice production business like FreshSqueeze Naturals. On average, the startup costs for a juice business can range from $50,000 to $150,000 depending on various factors such as location, equipment, and marketing strategies. Understanding how to acquire these funds effectively will set the foundation for your business's success.

Consider these main funding avenues:

- Personal Savings: Utilizing your own savings minimizes debt but requires a significant financial commitment.

- Bank Loans: Traditional banks offer loans, but expect to present a detailed business plan and financial projections to secure the necessary capital.

- Investors: Seeking angel investors or venture capital can provide substantial funding in exchange for equity in your company.

- Crowdfunding: Platforms like Kickstarter or Indiegogo allow you to pitch your juice business idea to potential backers, generating funds while validating your concept.

- Grants and Competitions: Look for local or national grants aimed at promoting organic food businesses. Participating in startup competitions can also provide funding opportunities.

In order to create a comprehensive financial plan, break down your projected juice production business costs into key categories:

- Equipment: Expect to invest around $20,000 to $50,000 for cold-pressed juicers and other essential machinery.

- Raw Ingredients: Monthly expenses for quality ingredients can range from $2,000 to $10,000 depending on sales volume and product variety.

- Licensing and Permits: Budget approximately $1,000 to $5,000 to cover local health regulations and food production permits.

- Marketing and Branding: A solid marketing strategy may require a budget of $5,000 to $15,000 to establish brand recognition and reach your target audience.

Tips for Securing Funds Effectively

- Prepare a detailed juice production startup budget to showcase to potential lenders or investors; include cost breakdowns for equipment, packaging, and operational expenses.

- Highlight the health trends and market potential for your juice business in your pitch; this can help convince investors of the viability of your venture.

- Networking is crucial; attend industry conferences and local business events to connect with potential investors and partners.

Investors are increasingly looking for informed decisions, hence providing a robust financial plan can lead to more favorable financing options. As you explore juice business financing opportunities, remember to highlight the sustainability aspect of FreshSqueeze Naturals, as environmentally-friendly practices often attract funding.

Researching industry benchmarks can also enhance your funding strategy. For instance, businesses in the beverage industry can expect up to a 20% growth rate annually. Use this data to demonstrate potential return on investment (ROI) when pitching to investors or lenders. For more insights on costs, consider reviewing this article on [juice production profitability](https://financialmodeltemplates.com/blogs/profitability/juice-production).

How to Use the Financial Plan for Your Juice Production Business?

Creating a financial plan for your juice production business is an essential step that lays the groundwork for sustainability and growth. A well-structured financial plan will help you navigate through the various startup costs for your juice business and ensure you are aware of the financial implications of your decisions. It serves as a blueprint for understanding your costs, projecting revenue, and securing juice business financing.

When developing your financial plan, you should start by breaking down your startup costs into manageable categories. This cost breakdown for juice business can include:

- Cold-pressed juicer and equipment costs

- Raw ingredients cost for juice

- Packaging expenses for juice

- Licensing fees for juice production

- Marketing budget for juice business

- Renting a juice production facility

- Insurance needs for juice production

- Startup permits for juice business

For instance, initial equipment investment can range from $10,000 to $50,000 depending on the scale of production. Meanwhile, raw ingredients cost for juice can vary significantly based on seasonality and sourcing methods, potentially impacting your juice production startup budget.

Utilizing this financial plan also means calculating your expected monthly expenses and revenue. This information can help you gauge the feasibility of your juice production business and set realistic profitability targets. According to industry benchmarks, many juice startups aim for a gross margin of about 30% to 40%.

Tips for Effective Financial Planning

- Regularly update your financial projections to reflect changing market conditions.

- Use software or templates specifically designed for juice production financial modeling to streamline calculations.

- Consider consulting with a financial advisor to refine your budgeting strategies.

Moreover, keeping track of your cash flows is crucial. You need to understand when your business will break even, which can often be a few months to a year after opening. If your estimated cost to start a juice business is around $75,000, it is essential to plan for adequate funding to cover operational costs until you start generating consistent revenue.

Finally, regularly review your financial plan against actual performance and make necessary adjustments to minimize juice business costs and optimize your investment strategies. By doing so, you will not only enhance your understanding of your juice business expenses but also develop a robust framework for growth.

What Are The Expenses To Start A Juice Production Business?

Starting a juice production business like FreshSqueeze Naturals involves a variety of expenses that you must carefully plan for to ensure success in the competitive beverage industry. The cost to start a juice business can vary widely based on factors such as location, equipment, and production scale. Here’s a detailed breakdown of the essential juice business expenses you need to consider:

Cold-Pressed Juicer and Equipment

Investing in high-quality juice production equipment is paramount. A cold-pressed juicer can range from $3,000 to $10,000, depending on the brand and capacity. Additionally, you’ll need other equipment such as blenders, storage containers, and cleaning tools, which can add another $1,000 to $3,000 to your startup costs for juice business.

Raw Ingredients and Inventory

The cost of raw ingredients can vary significantly based on your sourcing strategy. Buying organic, locally sourced produce may cost around $1,000 to $3,000 per month, depending on the amount of juice you intend to produce. This translates into a significant part of your juice production startup budget.

Packaging Materials

Effective and appealing packaging is vital for any juice brand. Expect to spend approximately $0.50 to $2.00 per bottle for bottles, labels, and caps. If you plan to produce 1,000 bottles per month, this could lead to an expense of $500 to $2,000 just for packaging.

Licensing and Permits

To operate legally, you must acquire necessary licenses and permits, which commonly cost between $1,000 and $5,000, depending on your location and the specific regulations surrounding food and beverage businesses. Always stay updated on licensing fees for juice production in your area.

Branding and Marketing Costs

Establishing a strong brand presence is crucial in attracting customers. Initial marketing expenses could range from $1,000 to $5,000, depending on whether you focus on digital marketing, local advertising, or influencer partnerships. A solid marketing budget for juice business should include social media campaigns, flyers, and promotional events.

Rent or Lease for Production Facility

If you're not producing juice at home, renting a production facility is necessary. Monthly rents can range from $1,500 to $5,000, depending on the location and size of the facility. It is essential to factor in these costs when calculating your startup expenses for juice production.

Utility Setup Costs

Utilities (water, electricity, and gas) are vital for running your juice production efficiently. Initial setup costs can be approximately $500 to $1,500, with ongoing monthly utility bills averaging $300 to $800.

Insurance Coverage

Insurance is necessary to protect your business from unforeseen events. Expect to spend about $500 to $2,000 annually on general liability and product liability insurance. This investment is crucial for mitigating risks associated with juice production.

Professional Services (Legal, Accounting)

Hiring professionals for legal and accounting advice is a wise investment. Engaging legal services may cost around $1,000, while accounting services could add another $1,000 to $3,000 annually. These services are essential to maintain compliance and streamline operations.

Tips for Minimizing Juice Business Costs

- Consider starting with smaller, less expensive equipment to reduce initial expenses.

- Utilize local farmers or community-supported agriculture (CSA) programs for lower raw ingredient costs.

- Engage in pre-sales or subscriptions to secure initial funding and minimize risk.

- Network with local businesses to share resources, such as facilities, and reduce rental costs.

Planning effectively for these juice production business costs will significantly enhance your chances of success. By understanding the landscape of startup costs for juice business, you can create a comprehensive financial plan to navigate the early stages of your operation. For more detailed financial insights, consider exploring this resource.

Cold-Pressed Juicer and Equipment

Starting a juice production business like FreshSqueeze Naturals requires a significant investment in cold-pressed juicing equipment, which is essential for creating high-quality juices. The **cost to start a juice business** often begins with the machinery needed to extract juice efficiently while preserving the nutrients and flavor of organic ingredients. The primary equipment you'll need includes:

- Cold-Pressed Juicer: Prices for high-quality cold-pressed juicers can range from $3,000 to $10,000, depending on the brand and capacity.

- Blenders: A commercial-grade blender can cost between $500 and $2,500, vital for creating bases and smoothies.

- Storage Tanks: Food-grade storage tanks for storing raw juices can set you back around $1,000 to $5,000.

- Filtration Systems: To ensure product safety, filtration systems can also add an additional cost of around $1,000 to $3,000.

- Cleaning Equipment: A significant aspect of food production, cleaning equipment and supplies may add another $500 to $1,000 to your costs.

In addition to juicers, various other equipment is vital for juice production, including:

- Labeling Machines: Essential for branding, with costs ranging from $1,000 to $3,500.

- Refrigeration Units: For storing perishable ingredients and finished products, expect to spend $2,000 to $10,000, depending on size and quality.

- Point of Sale System: Necessary for transactions, this can cost between $300 and $2,000.

Overall, the **juice production startup budget** primarily depends on the scale of your operation and the quality of equipment you choose. A reasonable estimate for equipment costs usually falls within the range of $10,000 to $30,000. To help you better understand these costs, here is a breakdown of a potential equipment investment:

| Equipment Type | Estimated Cost | Notes |

|---|---|---|

| Cold-Pressed Juicer | $3,000 - $10,000 | Essential for nutrient preservation |

| Commercial Blender | $500 - $2,500 | For smoothies and juice bases |

| Storage Tanks | $1,000 - $5,000 | Necessary for juice storage |

| Filtration System | $1,000 - $3,000 | Ensures product safety |

| Labeling Machine | $1,000 - $3,500 | For branding and compliance |

| Refrigeration Units | $2,000 - $10,000 | For ingredient and product storage |

Investing in the right equipment is crucial for the success of your juice production business. However, it’s important to find ways to minimize juice business costs without compromising quality. Here are a few tips:

Tips for Minimizing Equipment Costs

- Consider purchasing used equipment or refurbished items to lower upfront costs significantly.

- Explore leasing options for expensive juicers and machines to avoid large initial investments.

- Invest in multi-functional equipment that can perform various tasks to reduce the need for multiple machines.

The financing options for your equipment can also vary. Research local grants for food businesses, consider business loans tailored to startups, or explore crowdfunding if you need additional funds. Overall, the right equipment investment is essential for launching a successful juice production business while maintaining affordability and efficiency.

For a comprehensive financial plan that includes all your equipment and operational costs, consider utilizing resources like those found at this financial model for juice production.

Raw Ingredients and Inventory

One of the most significant components of startup costs for juice business is the procurement of raw ingredients and inventory. For FreshSqueeze Naturals, focusing on organic, locally sourced ingredients can enhance product quality and appeal. However, it does come with its own set of cost implications.

When estimating the juice production startup budget, consider the following key aspects:

- Ingredient Costs: The cost of fruits, vegetables, and other organic ingredients can fluctuate based on seasonality and supplier rates. On average, the cost of raw ingredients for a small-scale juice production might range between $1,000 to $3,000 per month.

- Inventory Management: Maintaining an adequate inventory is crucial, especially when considering the perishability of fresh produce. Investing in efficient storage solutions could help manage costs effectively.

- Supplier Relationships: Establishing relationships with local farmers can yield better rates, ensuring your juice business expenses remain manageable.

Here’s a cost breakdown for juice business financing:

| Ingredient Type | Cost Per Unit | Estimated Monthly Usage | Total Monthly Cost |

|---|---|---|---|

| Fruits | $2.00 | 500 lbs | $1,000 |

| Vegetables | $3.00 | 300 lbs | $900 |

| Herbs & Additives | $10.00 | 50 lbs | $500 |

| Total | $2,400 |

As you navigate your startup expenses for juice production, it’s essential to consider tips on minimizing costs:

Tips for Minimizing Raw Ingredients Costs

- Seasonal Buying: Purchase ingredients that are in season to reduce costs.

- Bulk Purchases: Consider buying in bulk to negotiate better pricing with suppliers.

- Local Sourcing: Engaging with local farmers can sometimes yield better rates and fresher ingredients.

In addition to raw ingredients, packaging materials play an essential role in inventory management. Investing in sustainable packaging can not only enhance your brand's image but also appeal to eco-conscious consumers, thereby potentially reducing your juice production business costs in the long run. Packaging expenses could range from $500 to $1,500 per month, depending on your production scale.

Finally, as you develop your financial plan, keep in mind that licensing fees for juice production and compliance with health regulations will also factor into your overall costs. Pursuing a transparent and efficient budgeting process now will help establish a solid foundation for your juice production journey.

By carefully assessing and managing your juicing business expenses, you can set the stage for a successful venture that aligns with your vision of providing delicious, health-oriented beverages.

For a detailed guide on creating your financial plan and understanding your costs better, you can check out this comprehensive resource: Juice Production Financial Model.

Packaging Materials

In the juice production business, particularly with a model like FreshSqueeze Naturals that emphasizes freshness and organic quality, the choice of packaging materials is critical. Not only does it play a significant role in preserving product quality and ensuring safety, but it also influences marketing and consumer perception. Packaging expenses for a juice business can vary widely based on materials, design, and sustainability options.

On average, packaging can account for approximately 20% to 30% of total startup costs for juice business operations. Below are common types of packaging materials you might consider:

- Glass Bottles: Often preferred for premium juices, offering a high-end look.

- Plastic Bottles: Lightweight and cost-effective, but may not appeal to all consumers.

- Pouches: Flexible and space-saving, suitable for on-the-go consumption.

- Labels and Branding: Essential for market differentiation, they can include legally required information and marketing graphics.

- Eco-friendly Options: Biodegradable materials or recycled plastics can attract environmentally-conscious consumers.

Tips for Reducing Packaging Costs

- Negotiate bulk purchasing agreements with suppliers to lower per-unit costs.

- Opt for minimalist designs that require fewer materials while still engaging consumers.

- Consider using returnable glass bottles to further reduce waste and costs over time.

When developing a juice production startup budget, it's essential to include a detailed breakdown of packaging expenses. For instance, if you project an initial production volume of 1,000 bottles per month, the following cost breakdown may apply:

| Packaging Type | Cost per Unit ($) | Total Monthly Cost ($) |

|---|---|---|

| Glass Bottles | 1.50 | 1,500 |

| Plastic Bottles | 0.80 | 800 |

| Labels | 0.30 | 300 |

Calculating these costs accurately can help ensure your juice production business costs remain manageable and in line with your financial projections. Additionally, keep in mind the importance of licensing fees for juice production, which can significantly impact your overall expenses. A well-planned packaging strategy can also elevate your branding efforts, as attractive containers can draw in consumers looking for high-quality options.

While it may be tempting to opt for the cheapest packaging solutions, balancing cost with quality is crucial to maintain the integrity of your product. Ensuring your packaging reflects the health-conscious values of your target market can be a game-changer in a competitive landscape. This approach aligns with your goals for marketing and consumer outreach, as effective branding coupled with quality packaging can help you capture a larger share of the market.

Licensing And Permits

Starting a juice production business like FreshSqueeze Naturals involves obtaining essential licenses and permits to legally operate. The costs associated with licensing can vary significantly based on your location and the scale of your business. On average, the licensing fees for juice production can range between $500 to $5,000 depending on various factors such as state regulations and local ordinances.

Here are some primary licenses and permits you may need for your juice business:

- Food Business License – Required to sell food products.

- Health Department Permit – Ensures compliance with health and safety standards.

- Business Registration – Legally registers your business with local authorities.

- Sales Tax Permit – Required if you plan to sell your product directly to consumers.

- Labeling Requirements – Adherence to FDA regulations for product labeling.

When budgeting for your juice production startup, it’s crucial to include not only the direct costs of these licenses but also the time and resources needed to navigate the application processes. Some states have streamlined processes, while others can be quite complex.

Tips for Managing Licensing Costs

- Research local regulations well in advance to anticipate potential costs.

- Consider consulting with a legal expert to ensure compliance with all laws.

- Look for local small business programs that may offer assistance with permits.

In addition to the direct costs of licenses, be aware of any ongoing fees that may arise post-application. For instance, annual renewal fees may range from $100 to $1,000 depending on the type of license. Therefore, when creating your juice production startup budget, factor in these recurring expenses as part of your long-term financial planning.

| License/Permit | Estimated Cost | Frequency |

|---|---|---|

| Food Business License | $200 - $1,000 | Annual |

| Health Department Permit | $100 - $500 | Annual |

| Business Registration | $50 - $300 | One-time |

| Sales Tax Permit | $30 - $100 | One-time or Annual |

Understanding the cost breakdown for juice business licensing and permits will help ensure that your venture adheres to legal guidelines and operates smoothly. This proactive approach can save you from potential fines or shutdowns that could jeopardize your juice production business investment strategies. For a detailed financial plan tailored to juice production, consider using resources available at https://financialmodeltemplates.com/products/juice-production-financial-model.

Branding and Marketing Costs

In the juice production business, specifically for an innovative brand like FreshSqueeze Naturals, branding and marketing costs are crucial elements that can significantly impact your overall startup budget. Establishing a strong brand identity and effectively marketing your products can help differentiate your juice offerings in a competitive market, attracting health-conscious consumers seeking nutritious alternatives.

On average, branding and marketing costs can range from 10% to 20% of your total startup expenses. Here's a breakdown of typical costs associated with building your brand and marketing your products:

| Expense Type | Estimated Cost | Notes |

|---|---|---|

| Logo Design | $500 - $3,000 | Professional design for brand identity. |

| Website Development | $1,000 - $5,000 | Responsive design optimized for e-commerce. |

| Social Media Advertising | $500 - $2,000/month | Targeted ads to reach potential customers. |

| Content Marketing | $300 - $1,500/month | Blog posts and videos to engage customers. |

| Promotional Events | $1,000 - $5,000 | Tastings and local fairs to increase brand visibility. |

Aside from these typical expenses, it’s essential to consider ongoing brand maintenance and promotional strategies. Allocating funds for consistent marketing efforts and exploring affordable juice production options can help manage your budget effectively.

Tips for Minimizing Branding and Marketing Costs

- Utilize social media platforms for organic reach rather than solely relying on paid ads.

- Collaborate with local businesses or influencers for co-marketing opportunities.

- Invest in quality content creation to improve visibility and customer engagement without recurring costs.

- Host free promotional events such as community juice tastings to build your customer base.

The juice business expenses related to branding and marketing are not just initial investments; they are ongoing commitments that contribute to the growth and sustainability of FreshSqueeze Naturals. Ensure you develop a comprehensive marketing budget that aligns with your overall business plan. A well-designed juice production startup budget can lead to effective brand recognition and customer loyalty over time.

Realizing the importance of branding and marketing in creating a robust market presence is vital. This aspect often involves substantial outlay, but the potential return on investment can far exceed the initial expenditure, particularly within health markets where consumers prioritize brand reputation and quality. For detailed insights, consider exploring comprehensive financial modeling resources, such as the one found at this link.

Rent or Lease for Production Facility

One of the most significant startup costs for your juice production business is the rent or lease for a production facility. The location and size of this facility can greatly influence your overall operational expenses and revenue potential.

In urban areas, rental rates for commercial spaces can range from $2 to $5 per square foot, while rural locations may offer lower rates, often between $1 to $3 per square foot. It's crucial to find a space that not only fits your budget but also meets health and safety regulations relevant to juice production.

Here are some factors that contribute to the overall cost of leasing a production facility:

- Size of the facility: A larger space may be necessary for equipment and storage, increasing costs.

- Location: Proximity to suppliers and customers can affect logistics and delivery expenses.

- Lease term: Short-term leases may have higher rates compared to longer commitments.

- Utilities: Costs for water, electricity, and waste disposal can add significantly to your monthly expenses.

Tips for Minimizing Facility Expenses

- Consider starting in a shared facility or co-packing arrangement to reduce initial costs.

- Negotiate lease terms to include a build-out period where rent is reduced while you set up the space.

- Look for government incentives or grants for businesses in the food and beverage sector in certain areas.

On average, a startup budget for a juice production business may allocate about 10-20% of total startup costs to rent or lease expenses. This percentage can be higher if you're in a prime location aimed at direct-to-consumer sales through retail or online channels.

| Location Type | Average Rent Per Sq Ft | Estimated Monthly Cost (1,000 sq ft) |

|---|---|---|

| Urban | $3.50 | $3,500 |

| Suburban | $2.50 | $2,500 |

| Rural | $1.50 | $1,500 |

Additionally, many juice production businesses are now considering affordable juice production methods, like starting operations in kitchen incubators, which can greatly reduce initial leasing expenses while providing necessary equipment and infrastructure. This setup is particularly beneficial for those looking to test their business model before committing to a long-term lease.

In conclusion, effectively managing your rent or lease expenses is crucial for setting up a successful juice production business. By carefully planning your budget and exploring various facility options, you can significantly reduce the financial burden during your startup phase.

For help creating a comprehensive financial plan tailored specifically to your juice production goals, consider utilizing professional resources that can guide your investment strategies, like those available here.

Utility Setup Costs

When starting a juice production business like FreshSqueeze Naturals, understanding the utility setup costs is crucial for accurate startup budgeting for juice business. These costs can vary significantly based on location, size of the facility, and the specific production processes employed. Essential utility setups typically include electricity, water, gas, and waste disposal services, which are fundamental for the operation of any juice production facility.

Here's a breakdown of what to consider when estimating utility costs for a juice production business:

- Electricity: Depending on the equipment used, electricity can be a significant expense. For instance, cold-pressed juicers and refrigeration units consume considerable energy. Monthly electricity costs can range from $500 to $1,500 or more, depending on the scale of production.

- Water: Fresh ingredients require a substantial amount of water for washing and production. Businesses should account for water supply and waste disposal, estimating monthly costs between $100 to $400.

- Gas: If the production facility requires gas for heating or other operations, this should be factored in as well. Monthly gas bills can average around $200 to $600.

- Waste Disposal: Proper waste management is crucial for compliance and sustainability. Expect to pay around $100 to $300 monthly for waste disposal services, depending on the volume and type of waste.

For a clearer understanding, here’s a sample utility cost table for a mid-sized juice production facility:

| Utility Type | Estimated Monthly Cost | Annual Cost |

|---|---|---|

| Electricity | $1,000 | $12,000 |

| Water | $250 | $3,000 |

| Gas | $400 | $4,800 |

| Waste Disposal | $200 | $2,400 |

| Total | $1,850 | $22,200 |

By anticipating these utility expenses and including them in your juice production startup budget, you can avoid potential financial pitfalls. Additionally, securing a reliable service provider for utilities from the outset can lead to better rates and service reliability.

Tips for Minimizing Utility Costs

- Choose energy-efficient equipment to reduce electricity consumption.

- Implement water-saving practices in your production process.

- Consider negotiating long-term contracts with utility providers for better rates.

In summary, understanding and carefully planning for utility setup costs is a vital step in launching a successful juice business. These costs are often overlooked but can have a significant impact on the overall viability of your juice production business plans. To further structure your financial outlook, take advantage of resources available at this financial model template, specifically designed to help juice entrepreneurs calculate and plan their startup expenses efficiently.

Insurance Coverage

When starting a juice production business like FreshSqueeze Naturals, understanding the insurance coverage necessary for operation is crucial. Adequate insurance protects your assets, ensures compliance with regulations, and safeguards against unforeseen risks. The following are essential types of insurance to consider:

- General Liability Insurance: This covers legal fees and settlements if someone is injured or their property is damaged due to your operations. For juice production, this is particularly relevant if customers consume your product on-site or if any incidents occur during deliveries.

- Product Liability Insurance: Especially important in the food and beverage industry, this protects against claims related to food safety and quality. If a consumer claims to have fallen ill from your juice, this insurance will help handle legal costs.

- Property Insurance: This covers damages to your production facility, equipment, and any inventory. Given the investment in juice production equipment, proper coverage is vital to mitigate potential losses from theft or natural disasters.

- Workers' Compensation Insurance: If you hire employees for juice production, this insurance is mandatory in many areas. It covers medical expenses and lost wages for employees injured on the job.

- Business Interruption Insurance: This helps replace lost income if your business is forced to close temporarily due to a covered event, such as a fire or flooding at your facility.

The average annual cost for these insurance policies can vary widely based on your location, the size of your operation, and the level of coverage required. On average, small businesses may pay between $500 to $3,000 annually for comprehensive coverage. Having a detailed financial plan that factors these juice business expenses is essential to avoid unexpected costs.

Here’s a breakdown of estimated insurance costs for a juice production startup:

| Type of Insurance | Estimated Annual Cost |

|---|---|

| General Liability Insurance | $600 - $2,000 |

| Product Liability Insurance | $500 - $1,500 |

| Property Insurance | $800 - $2,500 |

| Workers' Compensation Insurance | $1,000 - $3,000 |

| Business Interruption Insurance | $400 - $1,200 |

Tips for Managing Insurance Costs

- Shop around and compare quotes from multiple insurance providers to secure the best rates.

- Consider bundling different types of insurance policies with the same provider for potential discounts.

- Regularly review your insurance needs as your business grows to ensure that you are not overpaying for coverage.

To minimize overall startup costs for juice business, it's vital to approach insurance strategically. By ensuring you have the necessary coverage without overspending, you can help secure the financial foundation of your juice business. Furthermore, considering the financial model for juice production can provide insights into how to allocate your budget effectively, ensuring that insurance is a manageable expense rather than a financial burden. For more details, you can check out this comprehensive financial model for juice production.

Professional Services (Legal, Accounting)

Starting a juice production business like FreshSqueeze Naturals involves navigating a complex landscape of legal and financial obligations. Legal and accounting services are critical components of the startup costs for a juice business. These services ensure compliance with regulations and the efficient management of finances, both of which are crucial for the sustainability of your business.

Here’s a breakdown of the key professional services needed for your juice production startup:

- Legal Fees: Engaging a lawyer to assist with business structure registrations, licensing, and permits can be a substantial initial cost. Legal fees can range from $500 to $5,000, depending on the complexity of the services.

- Accounting Services: Hiring an accountant can help you manage your juice business expenses and prepare for tax obligations. Expect to spend around $300 to $2,000 annually, based on your revenue and transaction volume.

- Licensing and Permits: Depending on your location, acquiring necessary licenses (like health permits) could cost you anywhere from $200 to $1,500. These are non-negotiable expenses that need to be factored into your juice production startup budget.

Moreover, working with experienced professionals can save you money in the long run by avoiding potential fines and operational pitfalls associated with non-compliance.

Tips for Budgeting for Professional Services

- Consider hiring professionals on a project basis to minimize initial costs.

- Leverage free resources or online platforms for basic legal templates to reduce attorney fees.

- Utilize accounting software to track expenses and streamline financial management.

To paint a clearer picture of these costs, here’s a sample cost structure for your juice production business:

| Service | Estimated Cost | Frequency |

|---|---|---|

| Legal Fees | $1,500 | One-time |

| Accounting Services | $1,000 | Annual |

| Licensing Fees | $800 | One-time |

These figures indicate that the cost to start a juice business can be managed effectively with a clear understanding of professional service expenses.

Additionally, while considering juice business financing, highlight your plan to potential investors, ensuring they are aware of the comprehensive financial strategy you've laid out, including your budget for legal and accounting services. Having a solid financial plan can bolster confidence in your business model.

For more detailed financial templates specific to the juice production industry, you can explore resources at this link.